содержание .. 1544 1545 1546 1547 ..

Nissan X-Trail 32. Manual - part 1546

LU-20

< PRECAUTION >

[QR25DE]

PRECAUTIONS

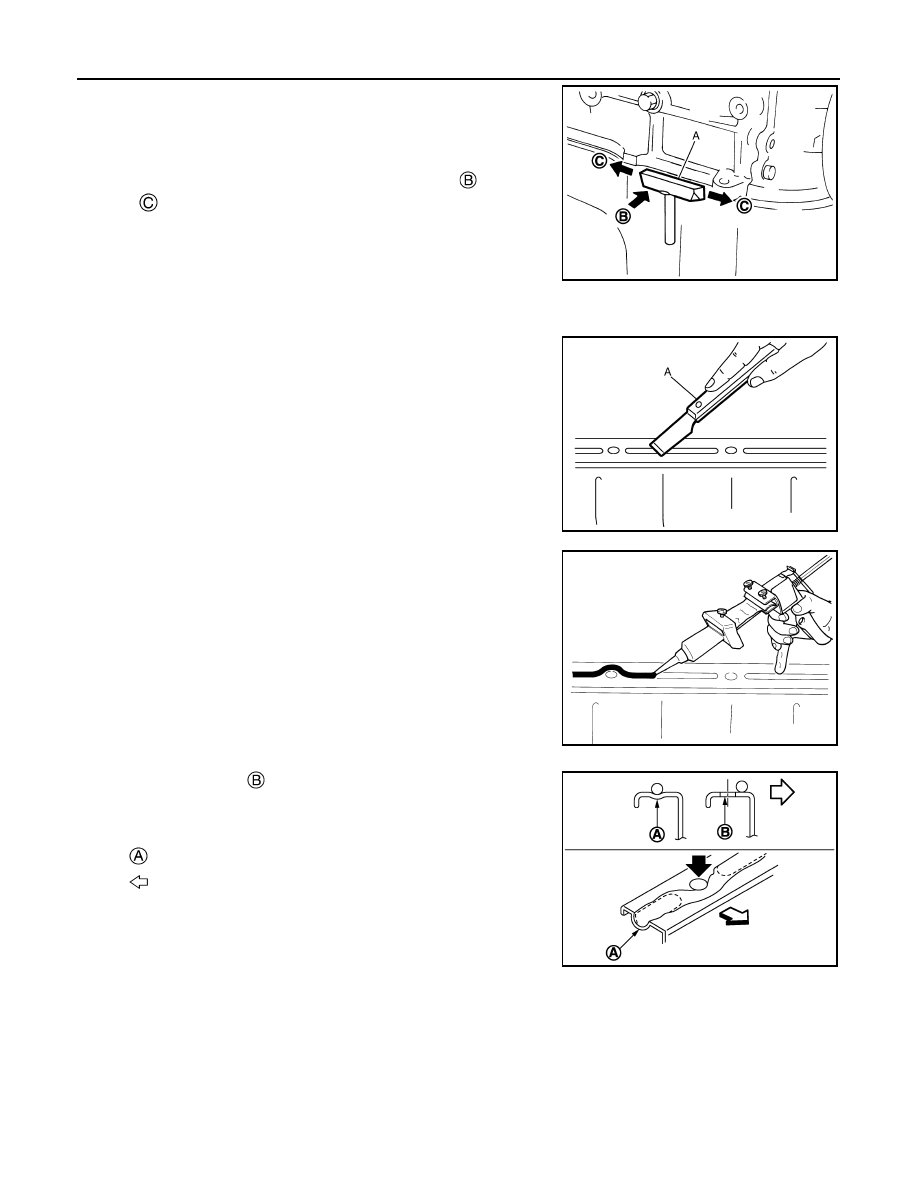

• After removing mounting nuts and bolts, separate the mating sur-

face using the seal cutter [SST: KV10111100] (A) and remove old

liquid gasket sealing.

CAUTION:

Never damage the mating surfaces.

• Tap the seal cutter [SST: KV10111100] to insert it

, and then

slide it

by tapping on the side as shown in the figure.

• In areas where the seal cutter [SST: KV10111100] is difficult to use,

lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1.

Using a scraper (A), remove old liquid gasket adhering to the liq-

uid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, mounting bolts, and bolt holes.

2.

Wipe the liquid gasket application surface and the mating sur-

face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3.

Attach liquid gasket tube to the tube presser (commercial ser-

vice tool).

Use Genuine Liquid Gasket or equivalent.

4.

Apply liquid gasket without gaps to the specified location accord-

ing to the specified dimensions.

• If there is a groove for liquid gasket application, apply liquid

gasket to the groove.

• As for bolt holes

, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation.

• After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

: Groove

: Inside

JPBIA0010ZZ