содержание .. 1017 1018 1019 1020 ..

Nissan X-Trail 32. Manual - part 1019

LOW PRESSURE FUEL PUMP

EC-1205

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

LOW PRESSURE FUEL PUMP

Component Function Check

INFOID:0000000010935912

1.

CHECK FUEL PUMP FUNCTION

1.

Turn ignition switch ON.

2.

Pinch fuel feed hose with two fingers.

NOTE:

Fuel pressure pulsation should be felt on the fuel feed hose for 1 second after ignition switch is turned ON.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>>

EC-1205, "Diagnosis Procedure"

Diagnosis Procedure

INFOID:0000000010935913

1.

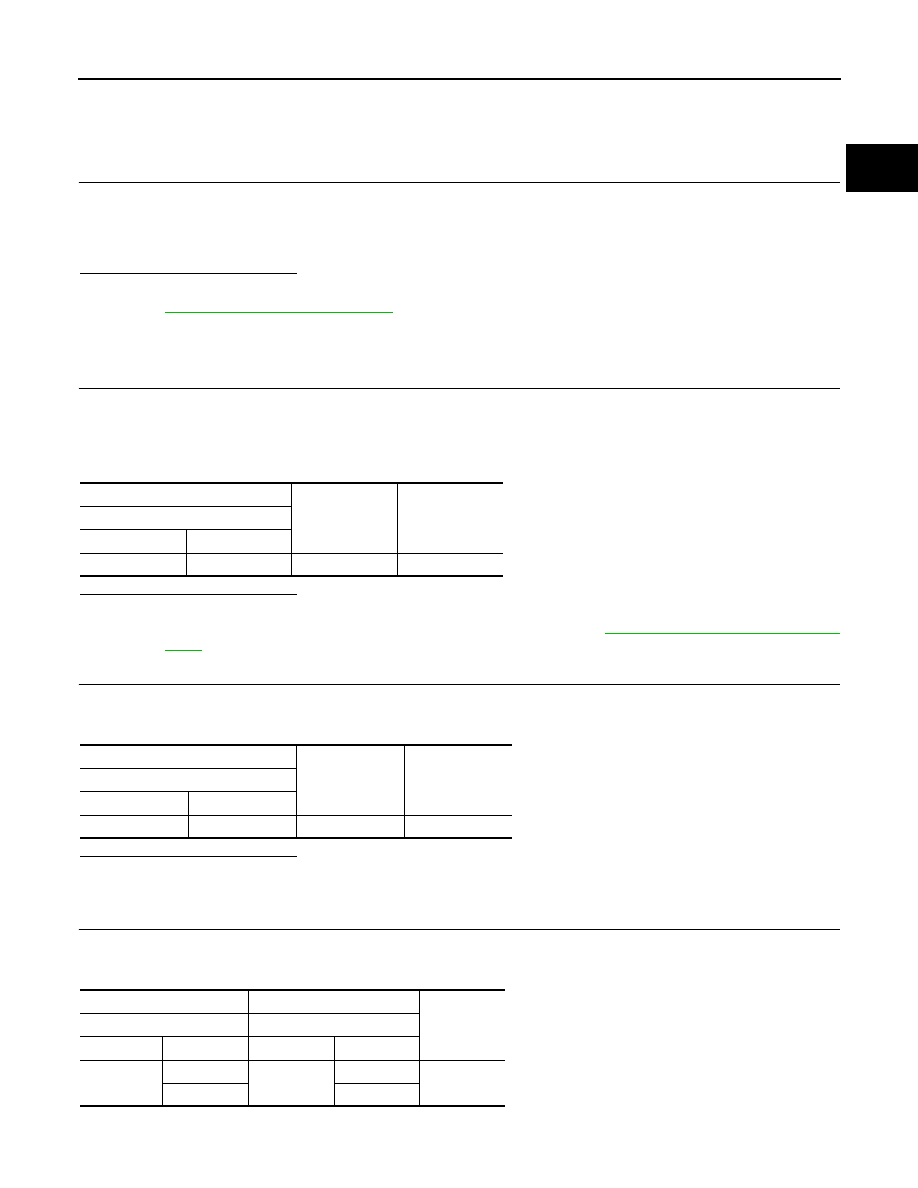

CHECK FPCM POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect FPCM harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between FPCM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Perform the trouble diagnosis for power supply circuit. Refer to

EC-963, "ECM : Diagnosis Proce-

.

2.

CHECK FPCM GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check the continuity between FPCM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit or short to power in harness or connectors.

3.

CHECK FPCM INPUT AND OUTPUT CIRCUIT

1.

Disconnect ECM harness connector.

2.

Check the continuity between FPCM harness connector and ECM harness connector.

3.

Also check harness for short to ground and to power.

+

−

Voltage

FPCM

Connector

Terminal

B132

8

Ground

Battery voltage

+

−

Continuity

FPCM

Connector

Terminal

B132

7

Ground

Existed

+

−

Continuity

FPCM

ECM

Connector

Terminal

Connector

Terminal

B133

9

E79

20

Existed

10

22