Nissan Qashqai J11. Manual - part 975

NORMAL OPERATING CONDITION

BRC-137

< SYMPTOM DIAGNOSIS >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

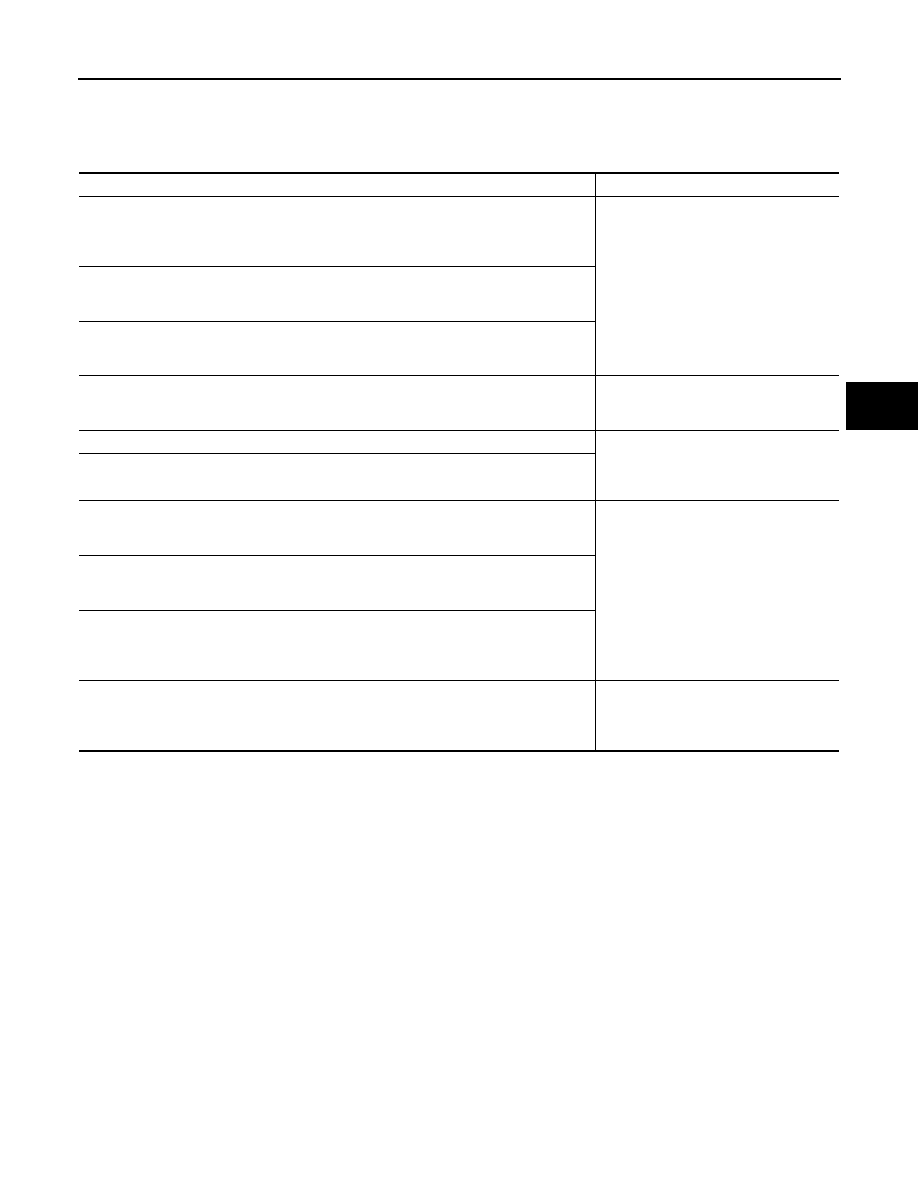

NORMAL OPERATING CONDITION

Description

INFOID:0000000010329888

Symptom

Result

Brake pedal slightly vibrates and operation sound (motor sound and sound from suspen-

sion) occurs when VDC function, TCS function, ABS function, EBD function, Brake limited

slip differential (BLSD) function, Brake assist function, hill start assist function or Brake

force distribution function operates.

This is not a malfunction, because it is

caused by VDC function, TCS function,

ABS function, EBD function, Brake limited

slip differential (BLSD) function, Brake

assist function, hill start assist function

and Brake force distribution function that

are normally operated.

Brake stopping distance may become longer than models without ABS function depending

on the road conditions, when ABS function is operated on slippery road like rough road,

gravel road or snowy road.

Brake pedal vibrates and operation sound occurs during sudden acceleration and corner-

ing, when VDC function, TCS function, Brake assist function or Brake force distribution

function is operated.

Brake pedal vibrates and motor sound from the engine room occurs, when the engine starts

or the vehicle starts just after starting the engine.

This is not a malfunction, because it is

caused by operation check of ABS actua-

tor and electric unit (control unit).

Acceleration may be felt insufficient depending on the road conditions.

This is not a malfunction, because it is

caused by TCS function that puts the

highest priority to obtain the optimum

traction (stability).

TCS function may operate momentarily, while driving on a road where friction coefficient

varies, or when downshifting, or fully depressing accelerator pedal.

ABS warning lamp and VDC OFF indicator lamp may turn ON, when the vehicle is on a ro-

tating turntable or is given a strong shaking or large vibrations on a ship while the engine is

running.

In this case, restart the engine on a nor-

mal road. If the normal condition is re-

stored, there is no malfunction. In that

case, erase “ABS” self-diagnosis result

memory with CONSULT.

VDC warning lamp may turn ON and VDC function, TCS function, Brake assist function,

and Brake force distribution function may not normally operate, when driving on a special

road the is extremely slanted (bank in a circuit course).

A malfunction in yaw rate/side/decel G sensor system may be detected when the vehicle

sharply turns during a spin turn, acceleration turn or drift driving while VDC function, TCS

function, are OFF (VDC OFF switch is pressed and VDC OFF indicator lamp is in ON sta-

tus).

The vehicle speed does not increase, when the accelerator pedal is depressed while the

vehicle is on a 2-wheel chassis dynamometer for speedometer check.

This is normal. (When checking the vehi-

cle on a chassis dynamometer, operate

VDC OFF switch so that TCS function is

OFF.)