Nissan Qashqai J11. Manual - part 812

DLN-164

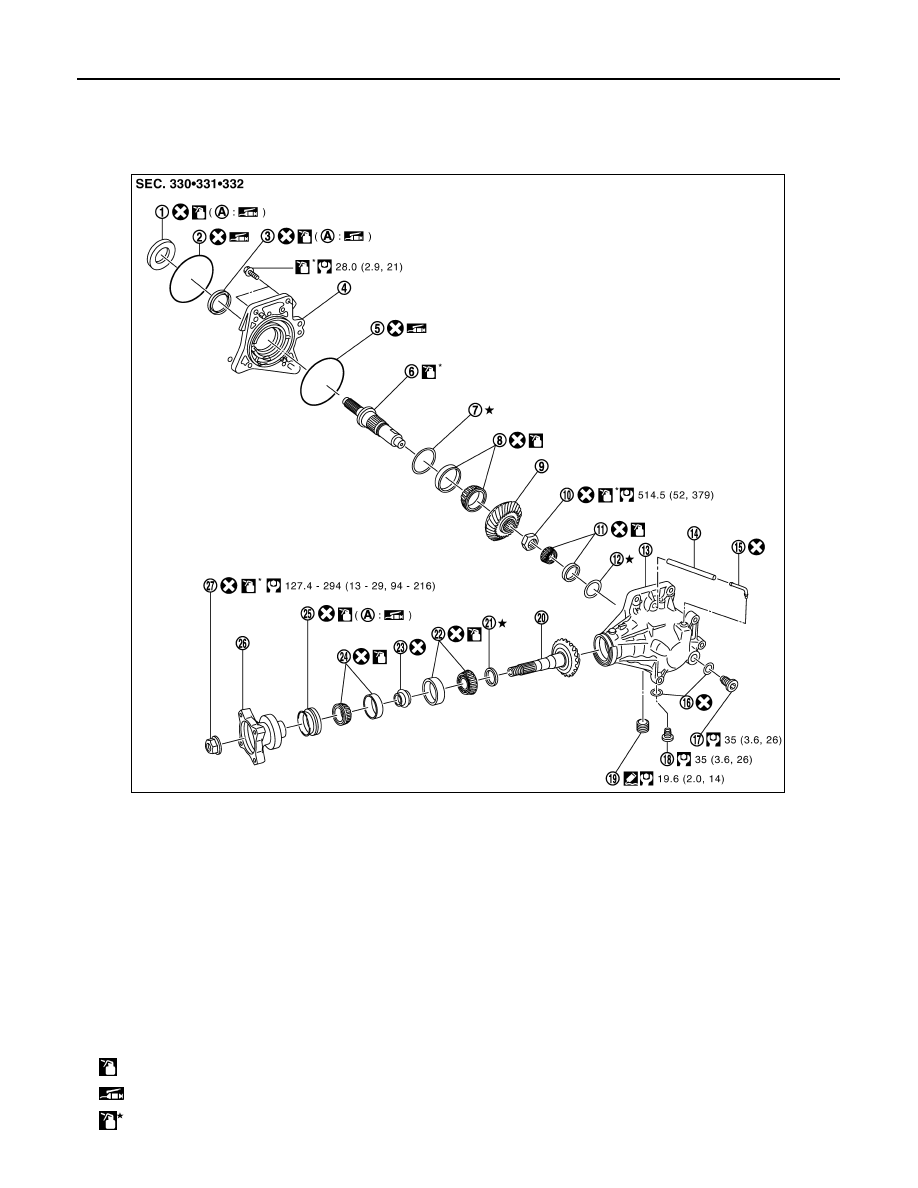

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY30A]

DRIVE PINION

DRIVE PINION

Exploded View

INFOID:0000000010288363

1.

Adapter case oil seal (outer)

2.

O-ring (outer)

3.

Adapter case oil seal (inner)

4.

Adapter case

5.

O-ring (inner)

6.

Ring gear shaft

7.

Ring gear adjusting shim

(adapter case side)

8.

Ring gear shaft bearing

(adapter case side)

9.

Ring gear

10. Ring gear nut

11.

Ring gear shaft bearing

(transfer case side)

12. Ring gear adjusting shim

(transfer case side)

13. Transfer case

14. Air breather hose

15. Air breather tube

16. Gasket

17. Filler plug

18. Drain plug

19. Plug

20. Drive pinion

21. Drive pinion adjusting shim

22. Drive pinion bearing (front side)

23. Collapsible spacer

24. Drive pinion bearing (rear side)

25. Drive pinion oil seal

26. Companion flange

27. Lock nut

A: Oil seal lip

: Apply gear oil.

: Apply multi-purpose grease.

: Apply anti-corrosive oil.

JSDIA0319GB