Content .. 2239 2240 2241 2242 ..

Nissan Qashqai J11. Manual - part 2241

DMS

ECO MODE SWITCH

DMS-17

< DTC/CIRCUIT DIAGNOSIS >

[ECO MODE (CVT)]

C

D

E

F

G

H

I

J

K

L

M

B

N

P

A

7.

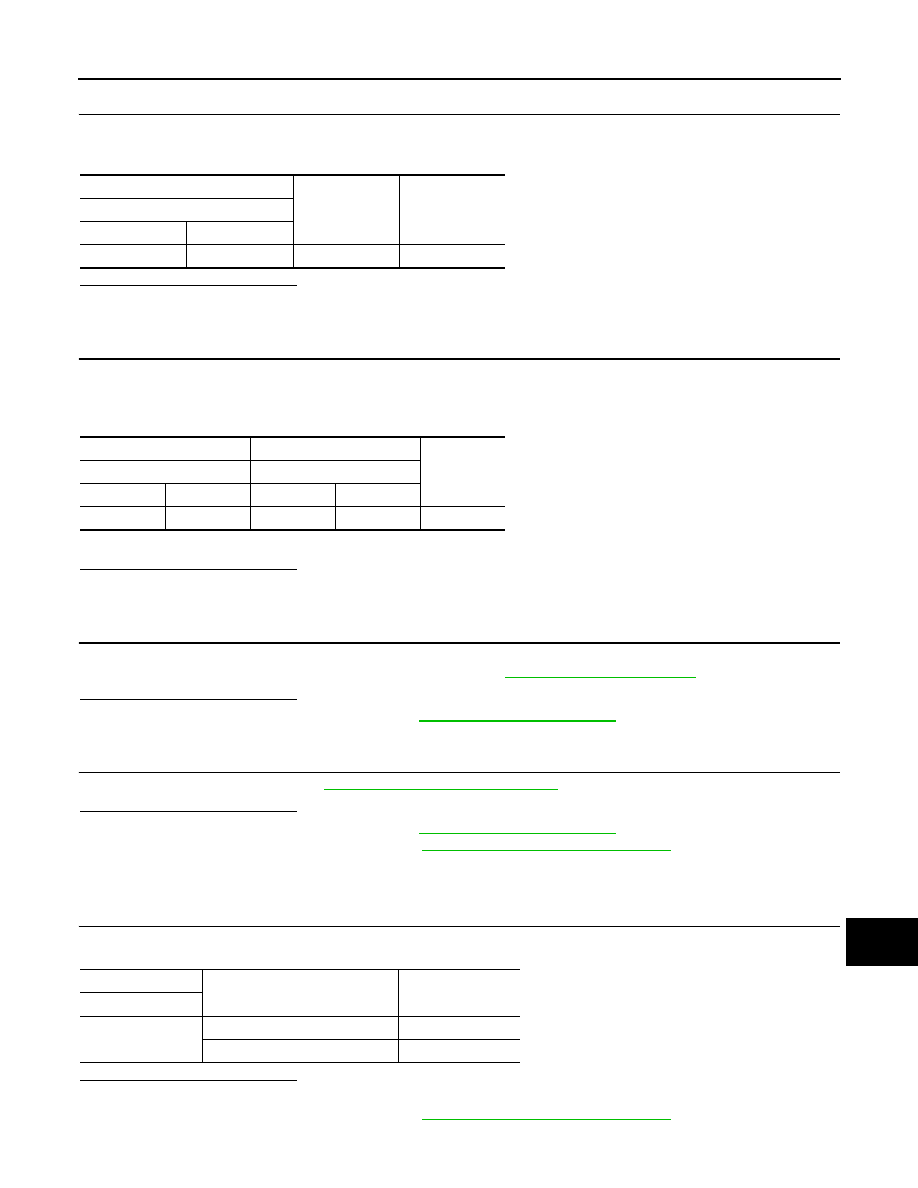

CHECK GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check the continuity between ECO mode switch harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair harness or connector.

8.

CHECK CIRCUIT BETWEEN COMBINATION METER AND ECO MODE SWITCH-1

1.

Disconnect combination meter harness connector.

2.

Check continuity between combination meter harness connector terminal and ECO mode switch harness

connector terminal.

3.

Also check harness for short to power and short to ground.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace damaged parts.

9.

CHECK COMBINATION METER INPUT/OUTPUT SIGNAL

1.

Connect all of disconnected connectors.

2.

Check input/output signal of combination meter. Refer to

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Repair or replace error detected parts.

10.

CHECK ECO MODE SWITCH

Check ECO mode switch. Refer to

DMS-17, "Component Inspection"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace ECO mode switch. Refer to

DMS-19, "Removal and Installation"

Component Inspection

INFOID:0000000010433950

1.

CHECK ECO MODE SWITCH

Check continuity between ECO mode switch connector terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace ECO mode switch. Refer to

DMS-19, "Removal and Installation"

+

−

Continuity

ECO mode switch

Connector

Terminal

M109

2

Ground

Existed

+

−

Continuity

Combination meter

ECO mode switch

Connector

Terminal

Connector

Terminal

M51

9

M109

1

Existed

ECO mode switch

Condition

Continuity

Terminal

1 – 2

ECO mode switch is depressed.

Existed

ECO mode switch is released.

Not existed