Nissan Qashqai J11. Manual - part 60

FLYWHEEL

EM-179

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Secure flywheel

with a stopper plate [SST: KV11105210]

(A), and tighten mounting bolts.

• Using TORX socket (size E20), tighten mounting bolts.

CAUTION:

Never damage or scratch and contact surface for clutch disc of flywheel.

Inspection

INFOID:0000000010715495

FLYWHEEL DEFLECTION

• Measure the deflection of flywheel contact surface to torque with a

dial indicator (A).

• Measure the deflection at 210 mm (8.27 in) diameter.

• If measured value is out of the standard, replace flywheel.

• If a trace of burn or discoloration is found on the surface, repair it

with sandpaper.

MOVEMENT AMOUNT OF FLYWHEEL

CAUTION:

Never disassemble double mass flywheel.

Movement Amount of Thrust (Fore-and-Aft) Direction

• Measure the movement amount of thrust (fore-and-aft) direction when 100 N (10.2 kg, 22 lb) force is added

at the portion of 125 mm (4.92 in) radius from the center of flywheel.

• If measured value is out of the standard, replace flywheel.

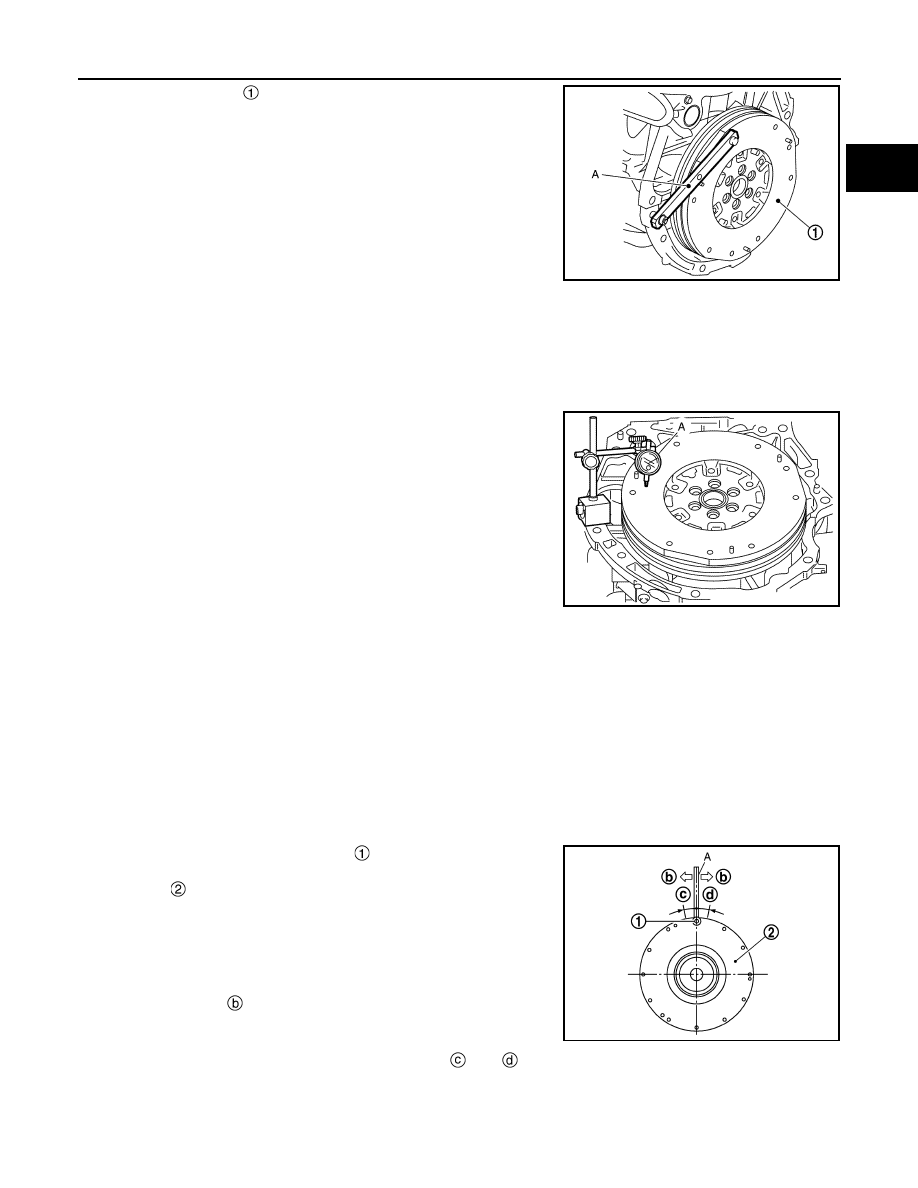

Movement Amount in Radial (Rotation) Direction

Check the movement amount of radial (rotation) direction with the following procedure:

1.

Install clutch cover mounting bolt

to clutch cover mounting

hole, and place a torque wrench (A) on the extended line of the

flywheel

center

line.

• Tighten bolt at a force of 9.8 N·m (1.0 kg-m, 87 in-lb) to keep it

from loosening.

2.

Put a mating mark on circumferences of the two flywheel

masses without applying any load (Measurement standard

points).

3.

Apply a force of

[9.8 N·m (1.0 kg-m, 87 in-lb)] in each direc-

tion, and mark the movement amount on the mass on the tran-

saxle side.

4.

Measure the dimensions of movement amounts

and

on circumference of the flywheel on the tran-

saxle side.

JSBIA1438ZZ

Limit : 0.45 mm (0.0177 in) or less.

JSBIA1439ZZ

Standard

: 1.8 mm (0.071 in) or less

Limit

: 33.2 mm (1.307 in) or less.

JPBIA6915ZZ