Nissan Juke F15. Manual - part 539

P0420 THREE WAY CATALYST FUNCTION

EC-969

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

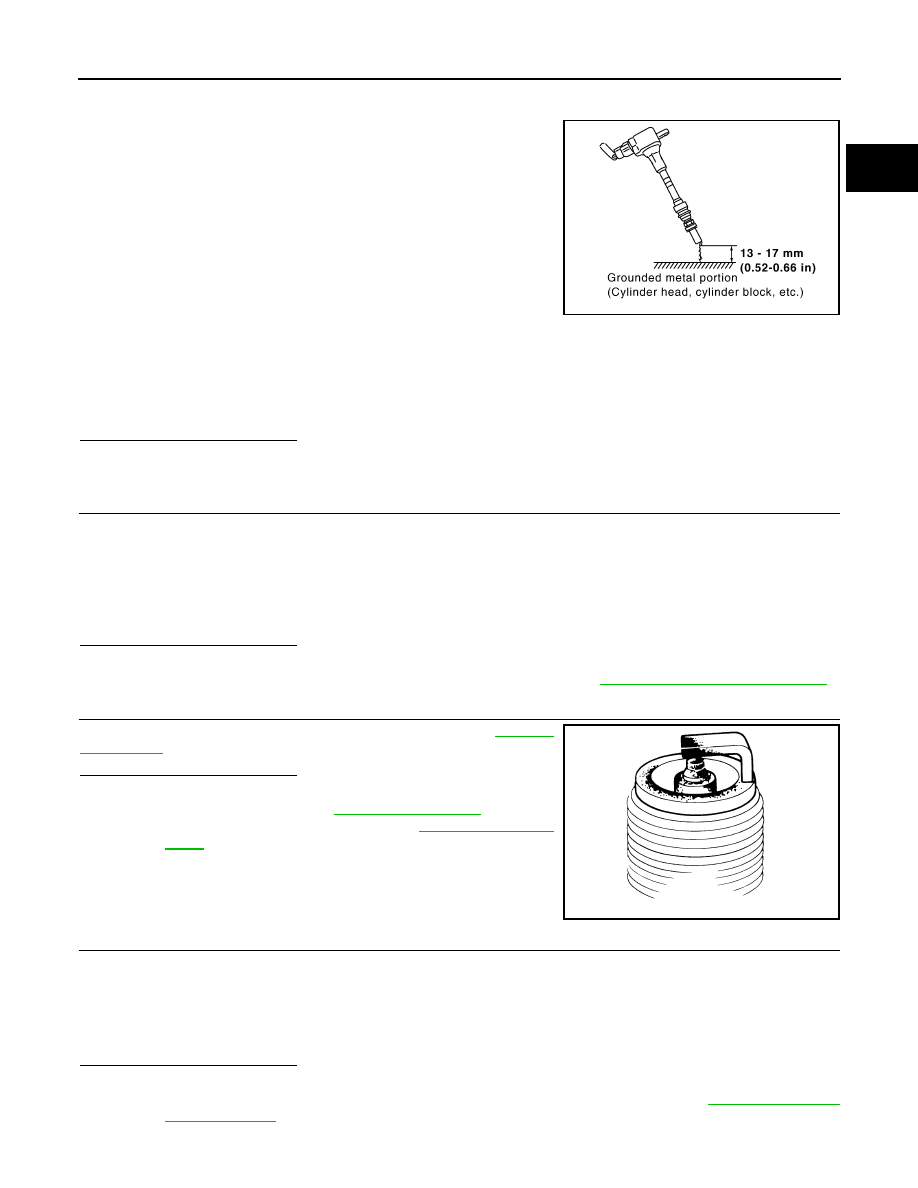

H

I

J

K

L

M

A

EC

N

P

O

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coil

within 50 cm (19.7 in). Be careful not to get an electrical

shock while checking, because the electrical discharge

voltage becomes 20 kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the spark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 7.

7.

CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded metal portion.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Check ignition coil, power transistor and their circuits. Refer to

EC-1229, "Diagnosis Procedure"

.

8.

CHECK SPARK PLUG

Check the initial spark plug for fouling, etc. Refer to

Is the inspection result normal?

YES

>> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to

NO

>> Repair or clean spark plug. Refer to

. Then GO TO 9.

9.

CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded portion.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace spark plug(s) with standard type one(s). For spark plug type, refer to

.

Spark should be generated.

JMBIA0066GB

Spark should be generated.

SEF156I

Spark should be generated.