содержание .. 342 343 344 345 ..

Nissan Tiida C11. Manual - part 344

EC-26

< BASIC INSPECTION >

[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

IDLE SPEED : Description

INFOID:0000000001161126

This describes how to check the idle speed. For the actual procedure, follow the instructions in “BASIC

INSPECTION”.

IDLE SPEED : Special Repair Requirement

INFOID:0000000001161127

1.

CHECK IDLE SPEED

With CONSULT-III

Check idle speed in “DATA MONITOR” mode with CONSULT-III.

With GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

IGNITION TIMING

IGNITION TIMING : Description

INFOID:0000000001161128

This describes how to check the ignition timing. For the actual procedure, follow the instructions in “BASIC

INSPECTION”.

IGNITION TIMING : Special Repair Requirement

INFOID:0000000001161129

1.

CHECK IGNITION TIMING

1.

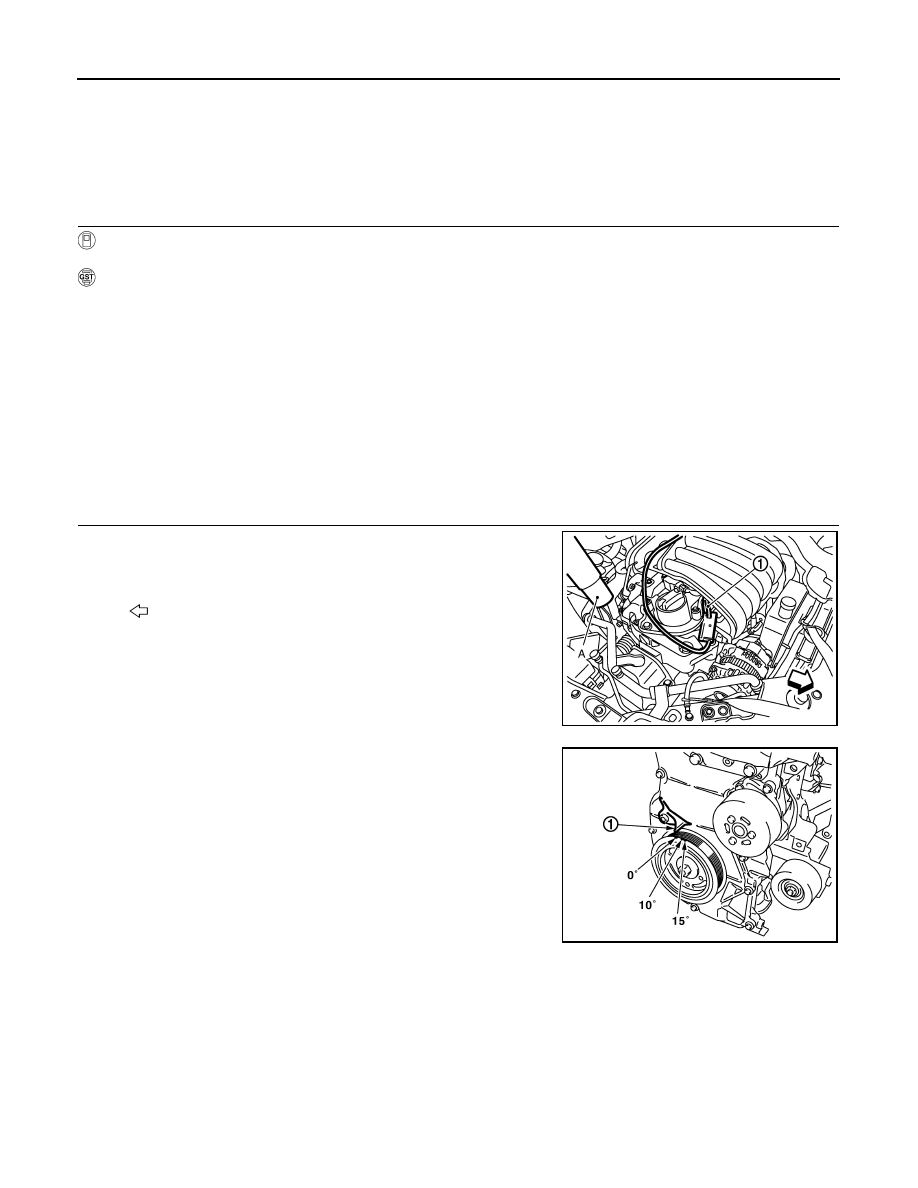

Attach timing light to No.1 ignition coil wire harness (1) as

shown.

2.

Check ignition timing.

>> INSPECTION END

ACCELERATOR PEDAL RELEASED POSITION LEARNING

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Description

INFOID:0000000001161130

Accelerator Pedal Released Position Learning is a function of ECM to learn the fully released position of the

accelerator pedal by monitoring the accelerator pedal position sensor output signal. It must be performed each

time harness connector of accelerator pedal position sensor or ECM is disconnected.

ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Re-

2

: Timing light

: Vehicle front

PBIB2955E

1

: Timing indicator

MBIB1331E