Mitsubishi Outlander XL. Manual - part 45

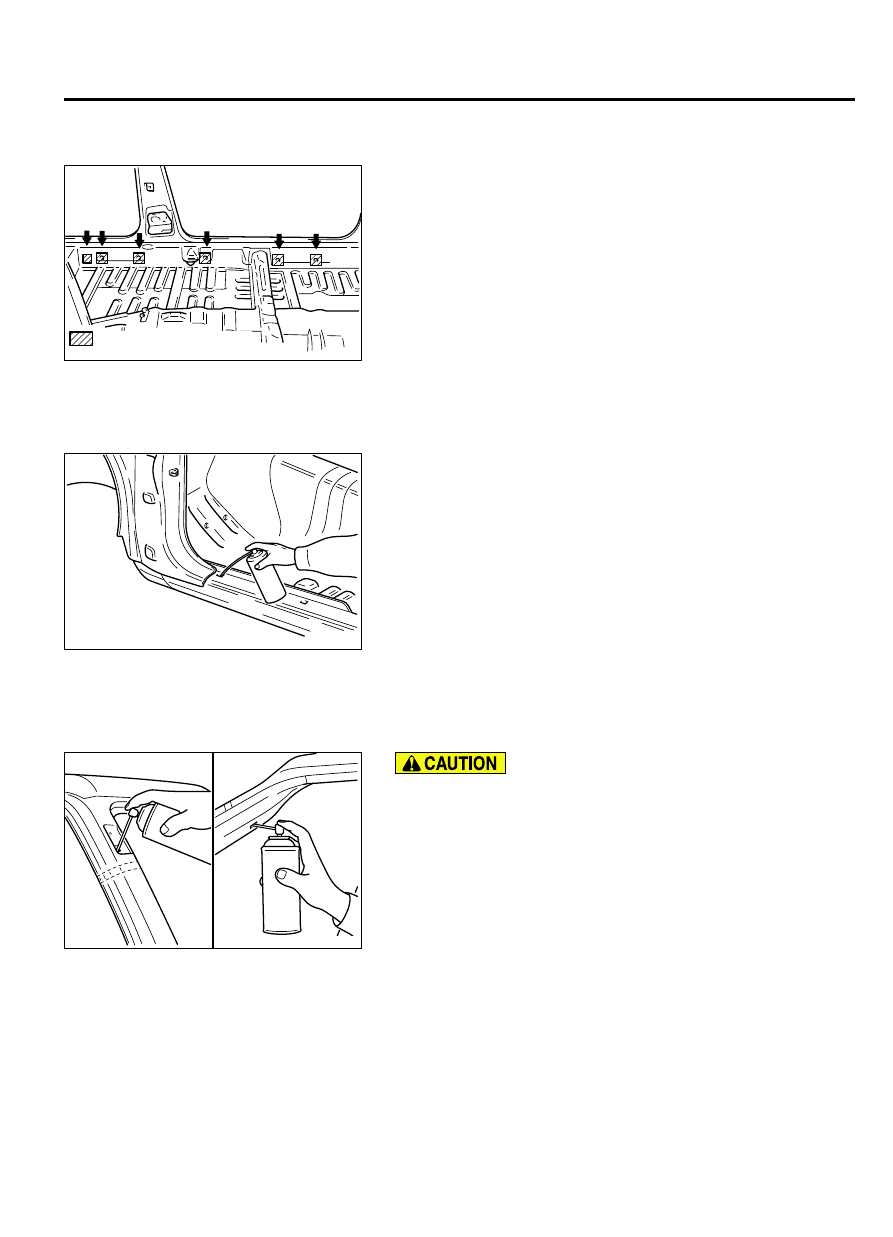

SEALING TAPE

ZB6002670000

: Locations for

attachment of sealing tape

Sealing tape is attached at unused holes, at the inner side of the

panel, for waterproofing and anticorrosion protection.

ANTICORROSION TREATMENT AT THE TIME OF

BODY REPAIR WORK

M40900000200USA0000010000

ZB6002680000

The following procedures should be followed for anticorrosion

protection when making repairs.

CORROSION PROTECTION FOR HOLLOW PARTS

ZB6002690000

⦆

Wipe away any excess anticorrosion agent on the coated

surface, because it can adversely affect the coating.

⦆

When spraying the anticorrosion agent, use holes in

different areas to ensure that all weld surfaces of the

hollow structure are well coated.

The insides of hollow parts (such as the side sill, pillars, etc.)

which have been welded are more susceptible to corrosion.

Spray an aerosol-type anticorrosion agent into these parts by

using the trim mounting holes and other openings.

ANTICORROSION TREATMENT OF ROUGH CUTS

An anticorrosion agent should be applied to rough cuts made in

the course of welding, because the surface film has been

damaged by the heat of welding.

BASE OF BODY REPAIR

9-39

CORROSION PROTECTION