Mitsubishi Montero (2004+). Manual - part 256

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-511

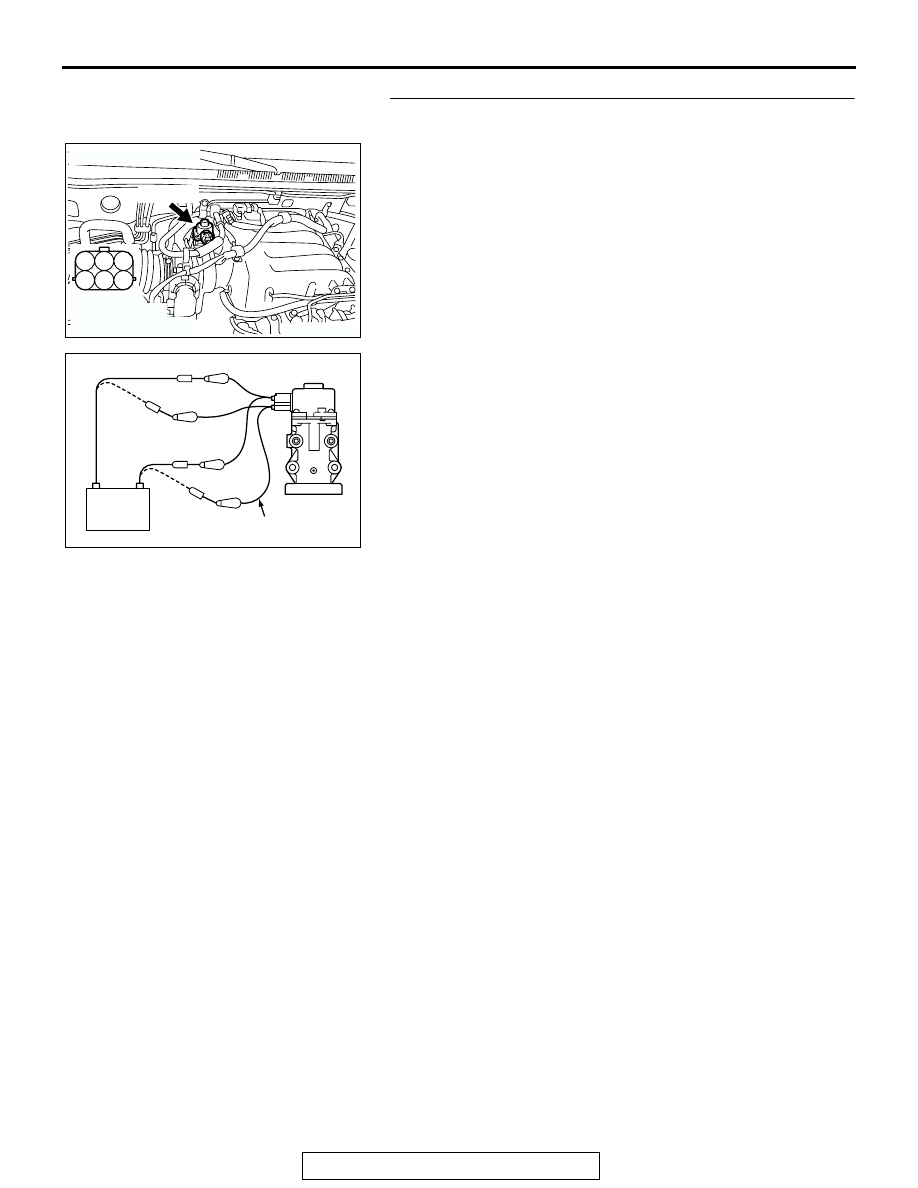

STEP 9. Check the EGR valve operation using special tool

MB991658.

(1) Remove the EGR valve.

(2) Connect special tool MB991658 to the EGR valve. (All

terminals should be connected.)

(3) Use the jumper wires to connect terminal No. 2 of the EGR

valve connector to the positive battery terminal.

(4) Check to ensure that the motor operates when the terminal

No. 1 and No. 3 of the EGR valve connector are

respectively connected to the negative battery terminal

using a jumper wire.

• Vibration should be present at each application of volt-

age to test clip combination.

(5) Then. Use jumper wires to connect the terminal No. 5 of the

EGR valve connector to the positive battery terminal.

(6) Check to ensure that the motor operates when the terminal

No. 4 and No. 6 of the EGR valve connector are

respectively connected to the negative battery terminal

using a jumper wire.

• Vibration should be present at each application of volt-

age to test clip combination.

(7) Reinstall the EGR valve, using a new gasket, and tighten to

the specified torque.

Tighten torque : 24

± 3 N⋅m [17 ± 3 ft⋅Ib]

Q: Is the EGR valve operating properly?

YES : Go to Step 10.

NO : Replace the EGR valve. Then go to Step 12.

AK200967

1

2

3

4

5

6

AB

HARNESS

CONNECTOR:

COMPONENT SIDE

B-56(GR)

CONNECTOR: B-56

AK000888

BATTERY

MB991658

AC