Content .. 1087 1088 1089 1090 ..

Mitsubishi Montero (2002-2004). Manual - part 1089

IGNITION SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-29

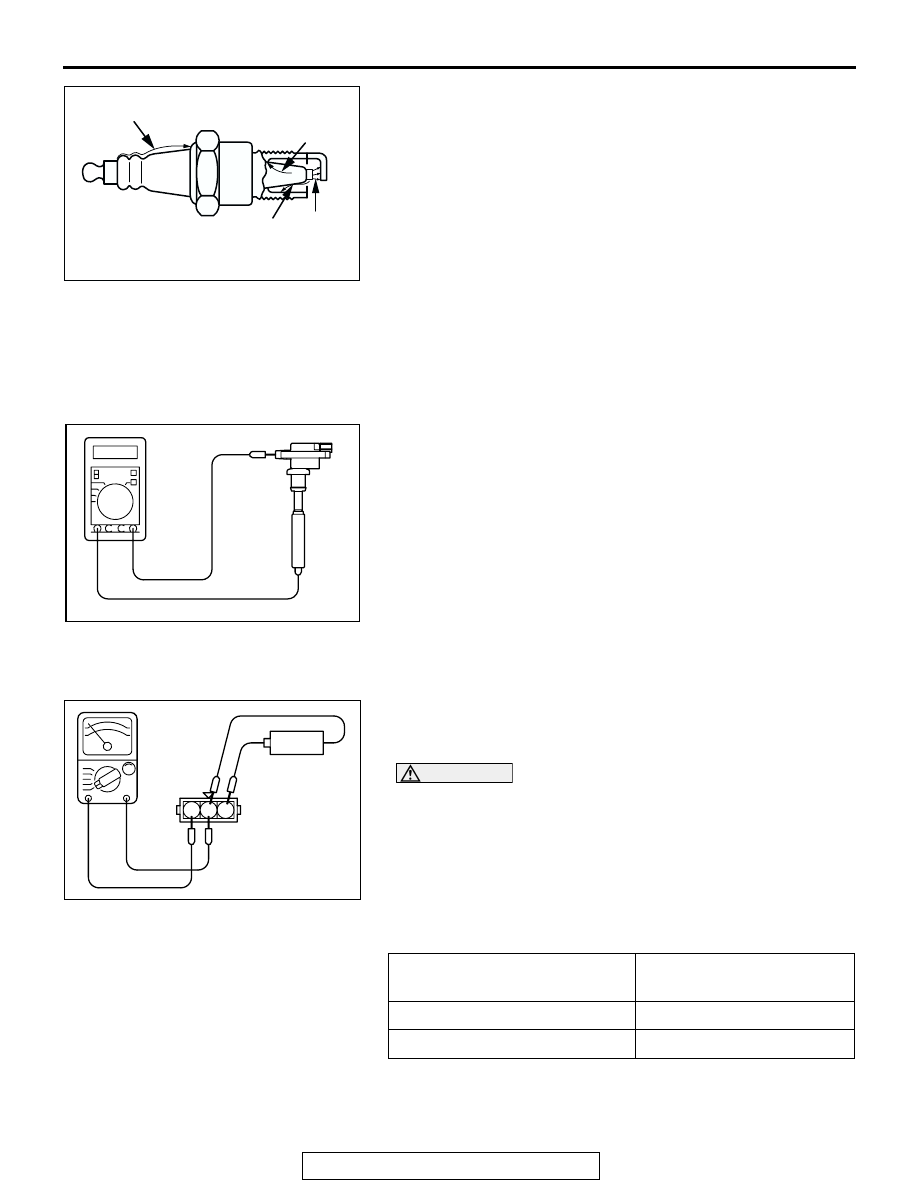

2. Ground the spark plug outer electrode (body), and crank the

engine.

Check that there is an electrical discharge between the

electrodes at this time.

IGNITION COIL CHECK

M1163001200153

Check by the following procedure, and replace the coil if there

is a malfunction.

.

SECONDARY COIL RESISTANCE CHECK

Measure the resistance between the high-voltage terminals of

the ignition coil.

Standard value: 8.5

− 11.5 kΩ

.

PRIMARY COIL AND IGNITION POWER TRANSISTOR

CONTINUITY CHECK

NOTE: An analog-type ohmmeter should be used.

NOTE: Connect the negative probe of the ohmmeter to termi-

nal 1.

CAUTION

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning and ignition power tran-

sistor from breaking.

1. Connect and disconnect 1.5 V battery between terminals 2

and 3, and observe the ohmmeter whether there is

continuity or not.

2. If results do not agree with the table below, replace the

primary coil and ignition power transistor assembly.

AKX00277

DEFECTIVE INSULATION

DEFECTIVE INSULATION

DEFECTIVE

INSULATION

GOOD

AB

AKX01264

1.5 V POWER SUPPLY

BETWEEN 2

− 3

CONTINUITY BETWEEN

1

− 2

Current flowing

Yes

Current not flowing

No

AKX01265AB

1.5 V

1 2 3

+

–