Mitsubishi Space Star. Manual - part 48

GDI –

Troubleshooting

13A-119

INJECTORS AND INJECTOR OPEN CIRCUIT CHECK

SIGNAL

The measurement method has been changed from the previous

description.

Measurement Method

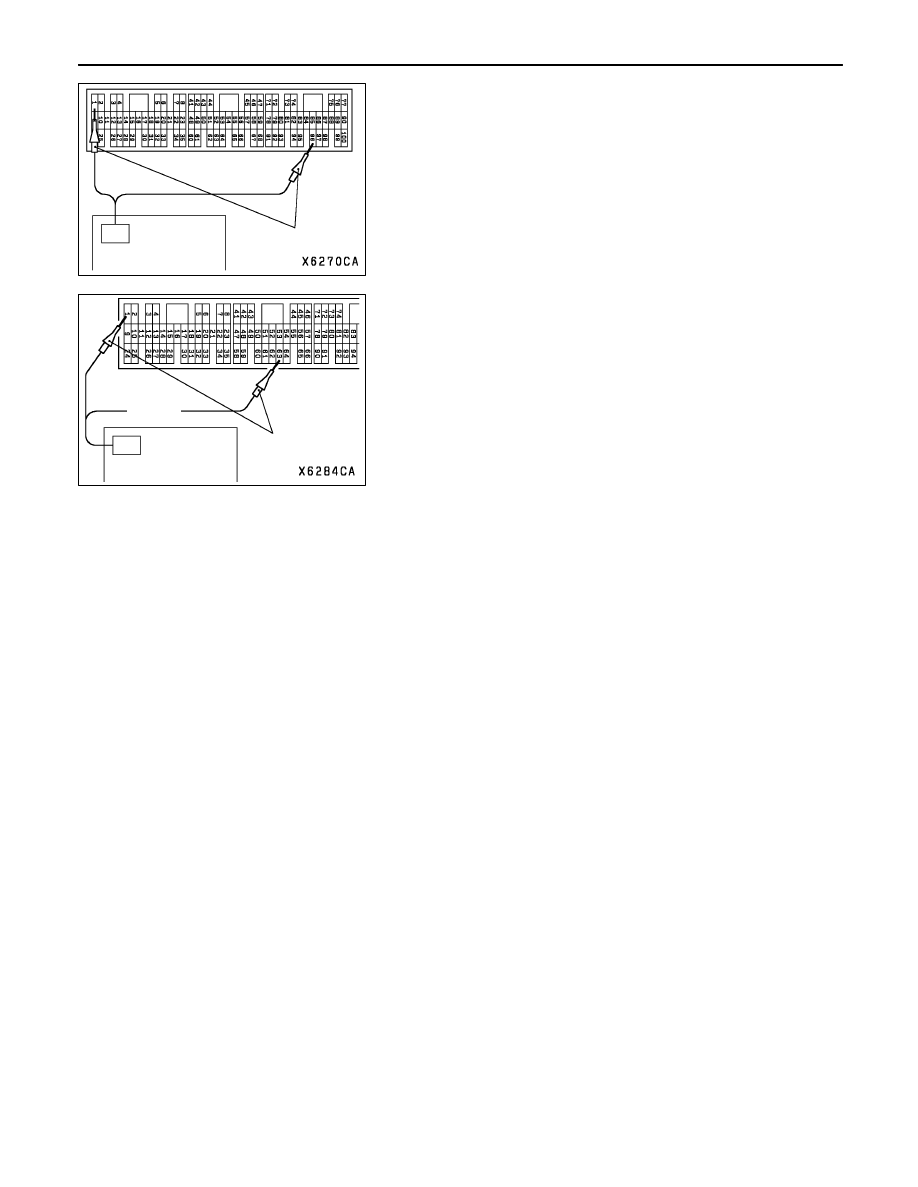

<Vehicles with M/T>

1.

Connect the analyzer special patterns pickup to terminal

1 (No. 1 injector) of the engine-ECU connector.

2.

Connect the analyzer special patterns pickup to terminal

96 (injector open circuit check signal) of the engine-ECU

connector.

3.

After checking terminal 1, check terminal 9 (No. 2 injector),

terminal 24 (No. 3 injector) and terminal 2 (No. 4 injector).

<Vehicles with A/T>

1.

Connect the analyzer special patterns pickup to terminal

1 (No. 1 injector) of the engine-A/T-ECU connector.

2.

Connect the analyzer special patterns pickup to terminal

63 (injector open circuit check signal) of the

engine-A/T-ECU connector.

3.

After checking terminal 1, check terminal 9 (No. 2 injector),

terminal 24 (No. 3 injector) and terminal 2 (No. 4 injector).

IGNITION COIL AND POWER TRANSISTOR

(Power transistor control signal)

The followings have been changed from the previous

description.

Alternate Method (Test harness not available)

<Vehicles with M/T>

Connect the analyzer special patterns pickup to engine-ECU

terminal 3 (No. 1 ignition coil), terminal 13 (No. 2 ignition

coil), terminal 12 (No. 3 ignition coil) and terminal 4 (No. 4

ignition coil) respectively.

<Vehicles with A/T>

Connect the analyzer special patterns pickup to

engine-A/T-ECU terminal 11 (No. 1 ignition coil), terminal 12

(No. 2 ignition coil), terminal 31 (No. 3 ignition coil) and terminal

30 (No. 4 ignition coil) respectively.

Special patterns

pickup

Analyzer

Special patterns

pickup

Analyzer