Mitsubishi Lancer Evolution X. Manual - part 512

SPECIAL TOOLS

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-5

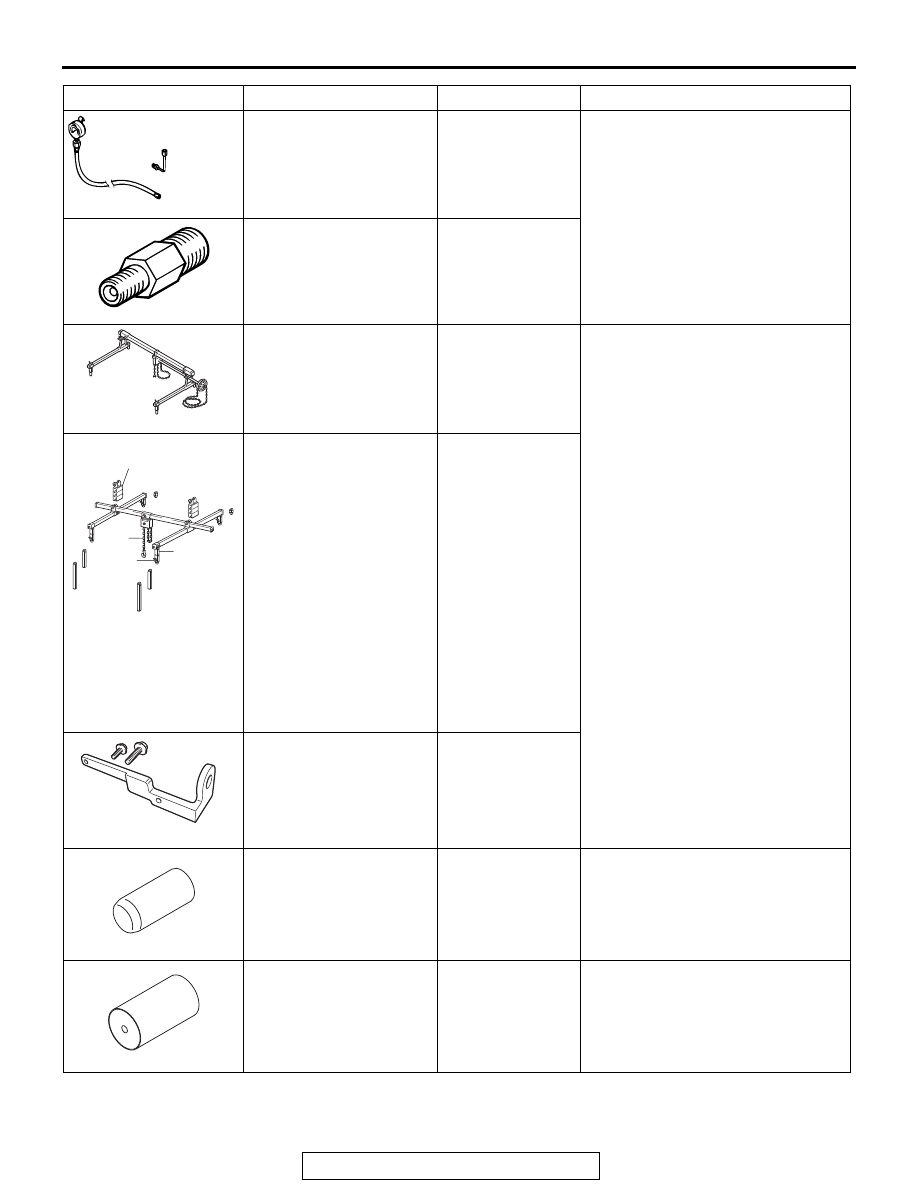

MD998330 (Includes

MD998331)

Oil pressure gauge (3.0

MPa, 427 psi)

MD998330-01

Measurement of hydraulic pressure

MB991705

Adapter

MB991895

Engine hanger

Tool not available When the engine hanger is used:

Supporting the engine assembly

during removal and installation of

the transaxle assembly

MB991928

Engine hanger

a: MB991929

Joint (50) × 2

b: MB991930

Joint (90) × 2

c: MB991931

Joint (140) × 2

d: MB991932

Foot (standard) × 4

e: MB991933

Foot (short) × 2

f: MB991934

Chain and hook

assembly

Tool not available

MB992201

Engine hanger plate

−

MB992311

Oil seal guide

−

Installation of transaxle case (LH)

oil seal

MB992310

Oil seal installer

−

Installation of transaxle case (LH)

oil seal

Tool

Tool number and name Supersession

Application

AC103525

MB991705

MB991895

B991928

a

b

c

d

e

f

Slide Bracket (HI)

B992201