Mitsubishi Lancer Evolution X. Manual - part 357

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-493

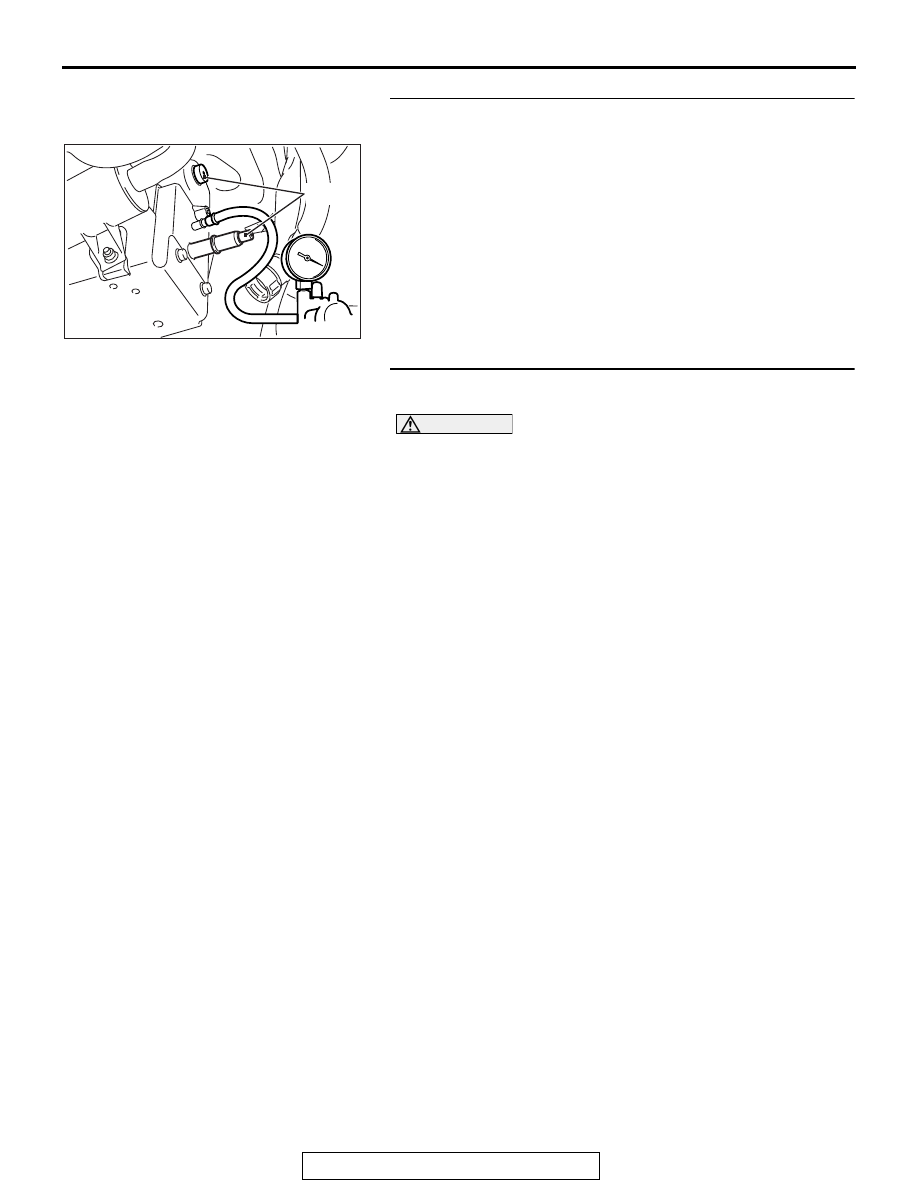

STEP 12. Check the evaporative emission canister for

vacuum leaks.

(1) Connect a hand vacuum pump to the evaporative emission

canister and plug the other nipples.

(2) Apply a pressure on the hand vacuum pump, and confirm

that air is maintained.

(3) Disconnect the hand vacuum pump and remove the plugs.

Q: Is the evaporative emission canister in good condition?

YES : Go to Step 13 .

NO : Replace the evaporative emission canister. Then go

to Step 14 .

STEP 13. Using scan tool MB991958, check the

evaporative emission system monitor test.

CAUTION

• During this test, the ECM automatically increases the

engine speed to 1,600 r/min or greater. Check that the

transaxle is set to "P" position.

(1) Turn the ignition switch to the "ON" position.

(2) Erase the DTCs using scan tool MB991958.

(3) Check that the fuel cap is securely closed (Tighten until

three clicks are heard).

(4) Start the engine.

(5) Select "Special Function"

(6) Select "Evap Leak Monitor"

(7) During the test, keep the accelerator pedal at the idle

position.

(8) Keep the engine speed and engine load within the specified

range. When the monitor test starts, the "In Progress" item

on scan tool MB991958 will change from "NO" to "YES".

(9) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is "Evap Leak Mon. Completed. Test Failed and DTCs

Set" displayed on scan tool MB991958?

YES : Replace the ECM. When the ECM is replaced,

register the ID code. Refer to GROUP 42B, ID Code

Registration Judgment Table <Vehicles with KOS>

or GROUP 42C, ID Code Registration

Judgment Table <Vehicles with WCM>

go to Step 14 .

NO <"Evap Leak Mon. Completed. Test Passed" is

displayed on scan tool MB991958.> : The evaporative

emission system is working properly at this time. Go

to Step 14 .

NO <"Evap Leak Mon. Discontinued. Retest again from

the first" is displayed on scan tool MB991958.> : The

EVAP monitor has been interrupted during the test.

Turn the ignition switch to the "LOCK" (OFF) position

once, and repeat the monitoring.

AK704702

AB

Plugs

AB