Mitsubishi Lancer Evolution IX. Manual - part 488

AC000872

Good

No good

AB

ON-VEHICLE SERVICE

SERVICE BRAKES

35A-7

(3) With the engine running, step on the brake

pedal and then stop the engine. Hold the

pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good

condition, if the pedal rises, the booster is

defective.

2. If the above three tests are okay, the booster is

OK. If one of the above three tests is not okay, the

check valve, vacuum hose, or booster is

defective. Check the check valve operation (Refer

to

), vacuum hose for leaks, high volume

engine vacuum applied to booster. Repair or

replace as necessary. If these are OK, replace the

booster and repeat this test starting at Step 1.

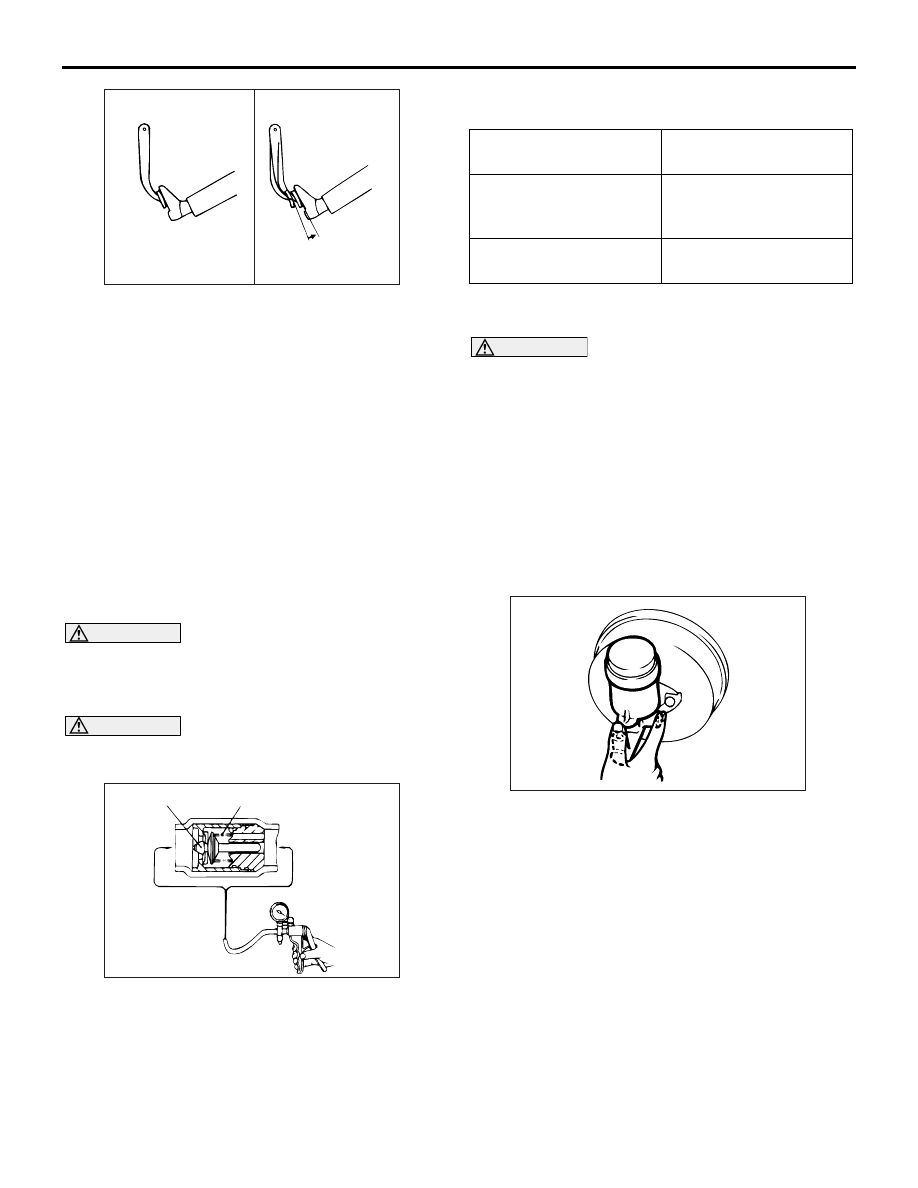

CHECK VALVE OPERATION CHECK

M1351009000462

CAUTION

The check valve should not be removed from the

vacuum hose.

1. Remove the vacuum hose (Refer to

).

CAUTION

If the check valve is defective, replace it as an

assembly unit together with the vacuum hose.

AC000873AE

A

B

Valve

Spring

Intake manifold

side

(does not hold)

Booster side

(holds)

2. Check the operation of the check valve by using a

vacuum pump.

Vacuum pump

connection

Accept/reject criteria

Connection at the brake

booster side (A)

A negative pressure

(vacuum) is created and

held.

Connection at the intake

manifold side (B)

A negative pressure

(vacuum) is not created.

BLEEDING

M1351001400552

CAUTION

Use only brake fluid DOT 3 or DOT 4. Never mix

the specified brake fluid with other fluid as it will

affect the braking performance significantly.

MASTER CYLINDER BLEEDING

The master cylinder has no check valve, so if bleed-

ing is carried out by the following procedure, bleed-

ing of air from the brake pipeline will become easier

(When brake fluid is not contained in the master cyl-

inder).

1. Fill the reserve tank with brake fluid.

2. Keep the brake pedal depressed.

AC000876

3. Have another person cover the master cylinder

outlet with a finger.

4. With the outlet still closed, release the brake

pedal.

5. Repeat steps 2

− 4 three or four times to fill the

inside of the master cylinder with brake fluid.