Mitsubishi Lancer Evolution VI. Manual - part 126

FULL-AUTOMATIC AIR CONDITIONER –

Troubleshooting /

On-vehicle Service

55-56

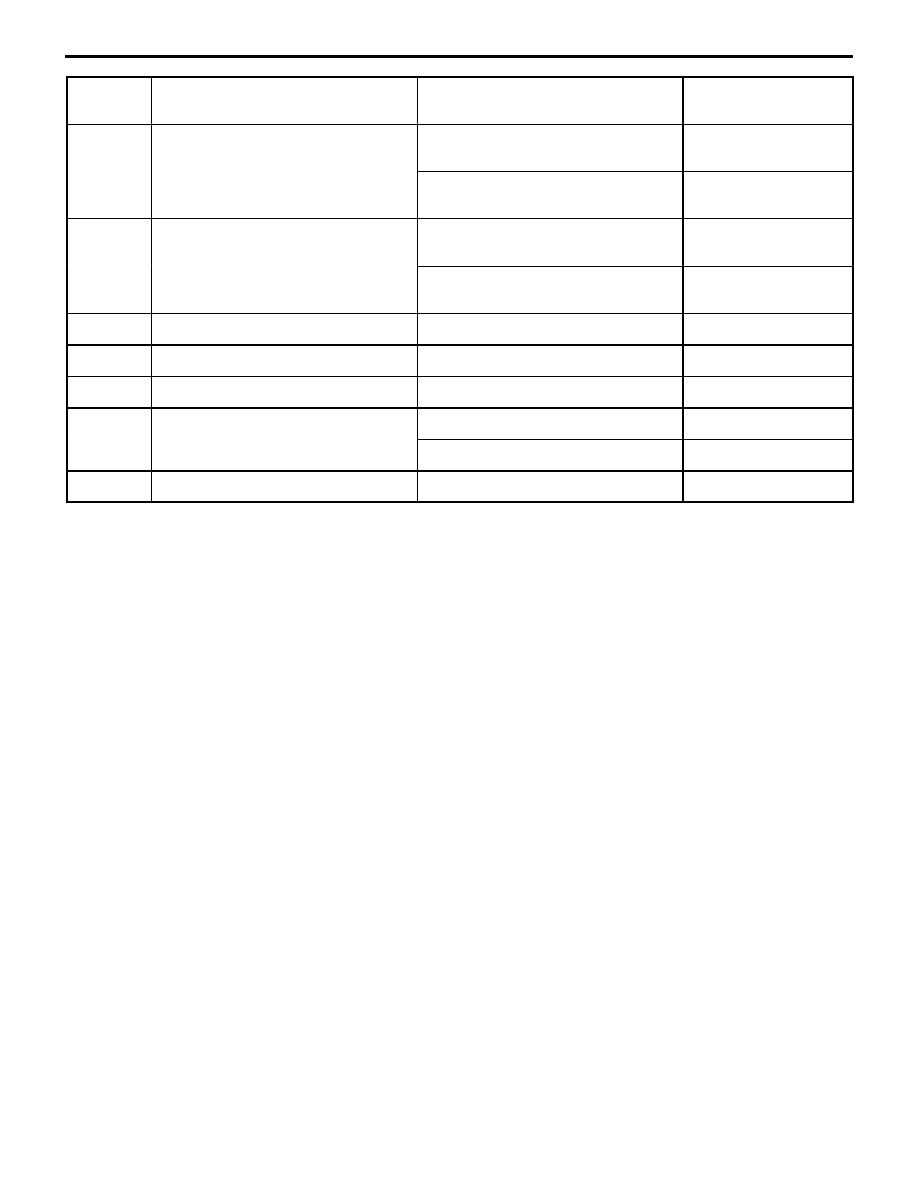

Terminal

No.

Normal condition

Check condition

Check item

25

Air mix damper motor (MAX. HOT)

When damper is moved to MAX.

COOL position

Almost no voltage

(0.5 V)

When damper is moved to MAX. HOT

position

10 V

26

Inside/outside air changeover damper

motor (Outside)

When switch is set to inside air

position

10 V

When switch is set to outside air

position

Almost no voltage

(0.5 V)

28

IG

2

power supply

When ignition switch is ON

System voltage

29

Earth

At all times

Continuity

30

ILL power supply

When lighting switch is at ON

System voltage

34

A/C output

When A/C is OFF

0 V

When A/C is ON

System voltage

35

Earth

At all times

Continuity

ON-VEHICLE SERVICE

REFRIGERANT CHARGING, LEVEL CHECK,

ADDITION AND REMOVAL, PERFORMANCE

TEST, DUAL PRESSURE SWITCH SIMPLE

CHECK

Follow the same procedures as for the heater and manual

air conditioner. (Refer to P.55-6.)