Mitsubishi Lancer Evolution VI. Manual - part 25

ENGINE –

Turbocharger

11-75

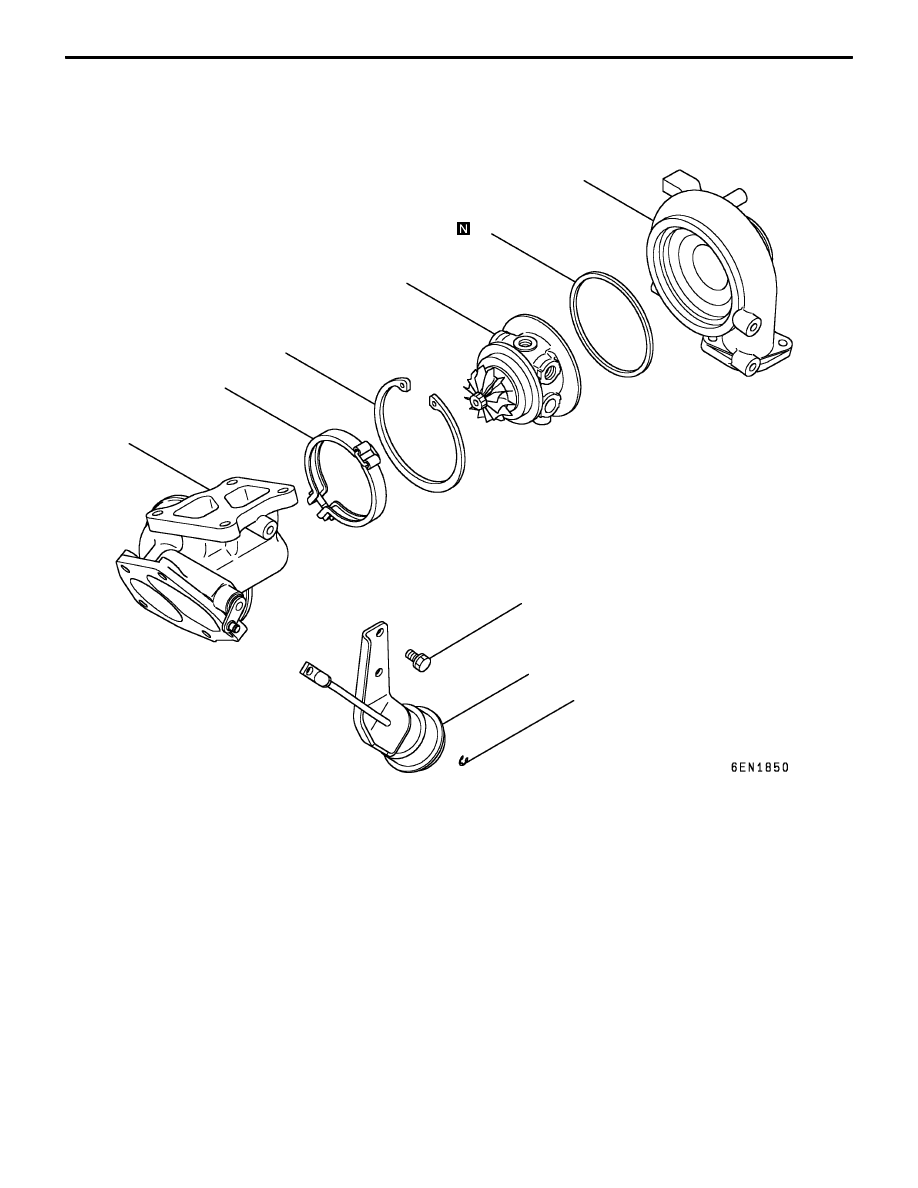

TURBOCHARGER

DISASSEMBLY AND REASSEMBLY

1

2

3

4

5

6

7

8

11 Nm

Disassembly steps

"

F

A D

Inspection of turbocharger waste gate

actuator operation

1. Snap pin

2. Waste gate actuator

"

E

A

3. Coupling

"

D

A

4. Turbine housing

A

A

" "

C

A

5. Snap ring

A

B

" "

B

A

6. Turbine wheel assembly

7. Compressor cover

"

A

A

8. O-ring