Mitsubishi Lancer Evolution VI. Manual - part 12

ENGINE –

Timing Belt

11-23

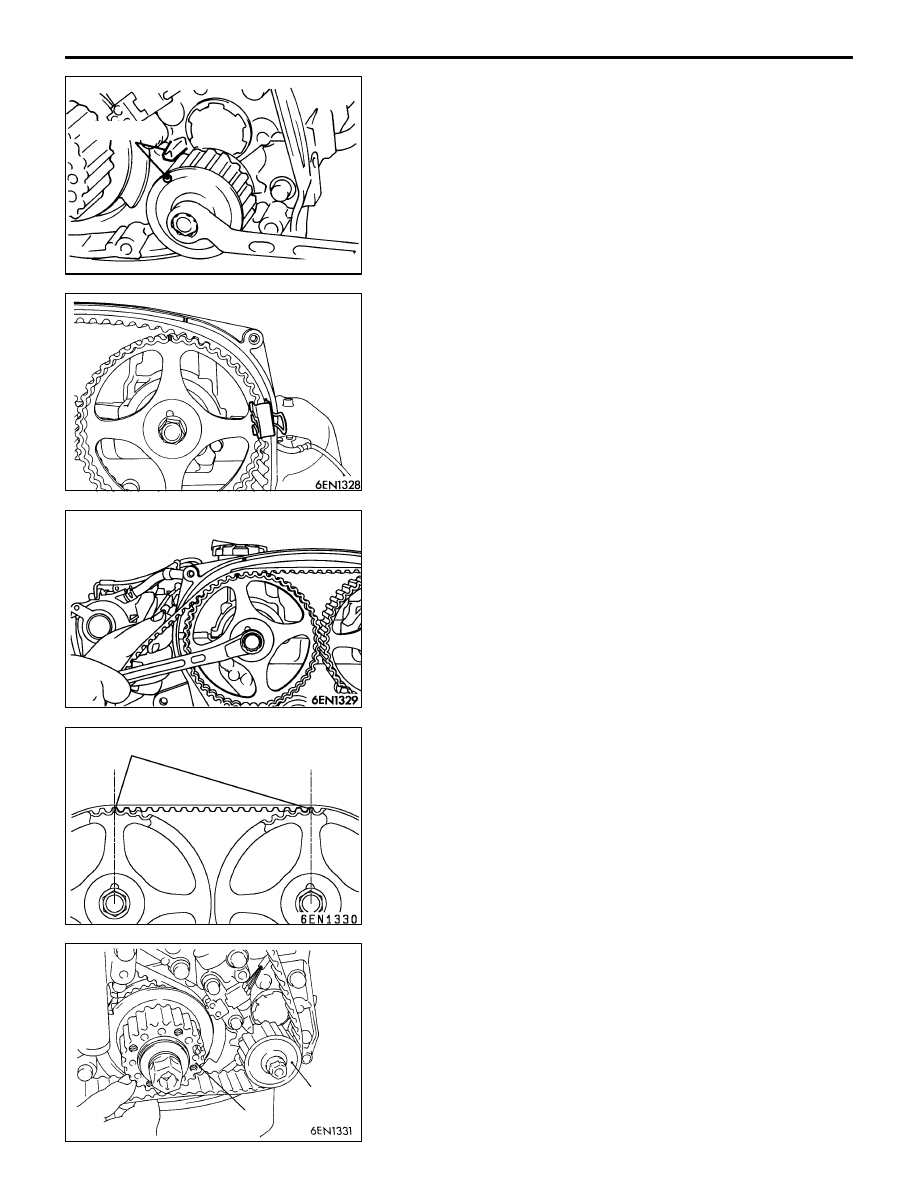

(6) Remove the Phillips screwdriver. Place the oil pump

sprocket in a position where its timing mark is one tooth

offset from the mated timing mark in the counterclockwise

direction.

(7) Fit the timing belt over the exhaust side camshaft sprocket,

and secure it at the illustrated position using a paper

clip.

(8) Turn the intake side camshaft sprocket as shown to a

position where its timing mark is one tooth offset from

the mated timing mark in the counterclockwise direction.

Then, fit the timing belt over the sprocket and secure

it with a paper clip.

NOTE

The intake camshaft will be turned a little clockwise by

the valve spring tension and stabilized in position even

if the belt is clipped at one tooth offset position.

(9) Check to ensure that the timing marks on the intake

camshaft sprocket side are in alignment when the exhaust

camshaft sprocket is turned clockwise to align the timing

marks.

NOTE

The timing belt span between the intake and exhaust

sprockets will have 17 cogs.

(10)Fit the timing belt over the idler pulley, oil pump sprocket

and crankshaft sprocket in this order.

NOTE

Be careful that the belt does not become slack.

Timing mark

6EN1327

Timing mark

Crankshaft

sprocket

Oil pump

sprocket