Mitsubishi Lancer Evolution VI. Manual - part 3

GENERAL –

How to Use Troubleshooting/Inspection Service Points

00-9

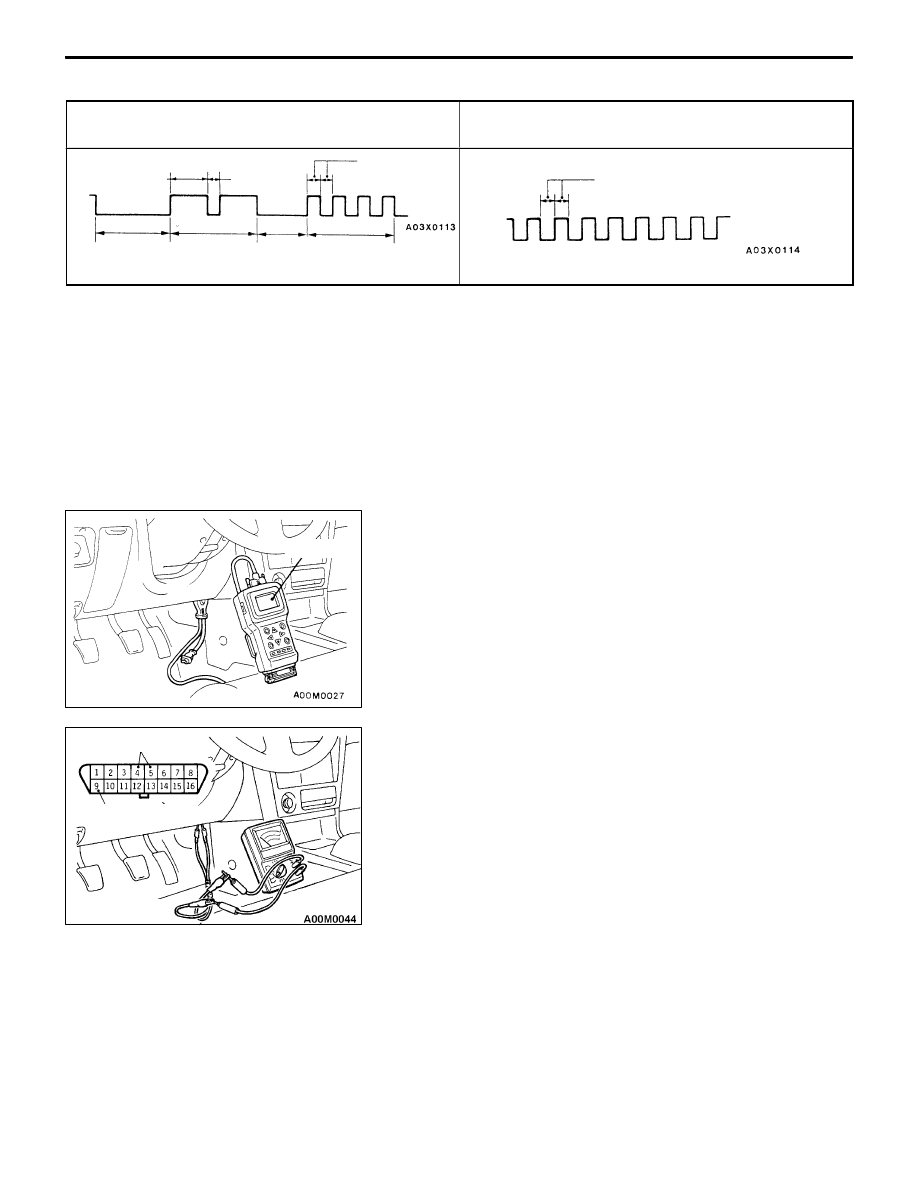

Diagnosis result display method when using a voltmeter

Example of diagnosis code voltage wave pattern for

diagnosis code No. 24

Normal voltage wave pattern

12V

0 V

1.5 secs.

0.5 sec.

0.5 sec.

Pause

time 3

secs.

Tens

signal

Place

division

2 secs.

Units

signal

12 V

0 V

0.5 sec.

METHOD OF ERASING DIAGNOSIS CODES

WHEN USING THE MUT-

II

Connect the MUT-

II

to the diagnosis connector and erase the diagnosis code.

Caution

Turn off the ignition switch before connecting or disconnecting the MUT-

II

.

WHEN NOT USING THE MUT-

II

(1) Turn the ignition switch to OFF.

(2) After disconnecting the battery cable from the battery (–) terminal for 10 seconds or more, reconnect

the cable.

(3) After the engine has warmed up, run it at idle for about 15 minutes.

INPUT SIGNAL INSPECTION POINTS <VEHICLES

WITH ETACS-ECU>

WHEN USING THE MUT-

II

1.

Connect the MUT-

II

to the diagnosis connector.

Caution

The MUT-

II

should be connected or disconnected after

turning the ignition switch to the OFF position.

2.

If buzzer of the MUT-

II

sounds once when the each switch

is operated (ON/OFF), the ETACS-ECU input signal for

that switch circuit system is normal.

WHEN USING VOLTMETER

1.

Use the special tool to connect a voltmeter between

the earth terminal (No. 4 or 5) and the ETACS terminal

(No. 9) of the diagnosis connector.

2.

If the voltmeter indicator deflects once when the each

switch is operated (ON/OFF), the ETACS-ECU input signal

for that switch circuit system is normal.

MUT-

II

Earth terminal

ETACS terminal

MB991529