Mitsubishi L200. Manual - part 396

Bearing type

Bearing

lubrication

Turning torque

New

None (with anti-

rust agent)

0.59

− 0.88 N⋅m

New or reuse

Gear oil applied 0.39

− 0.49 N⋅m

DIFFERENTIAL CARRIER ASSEMBLY

REAR AXLE

27-35

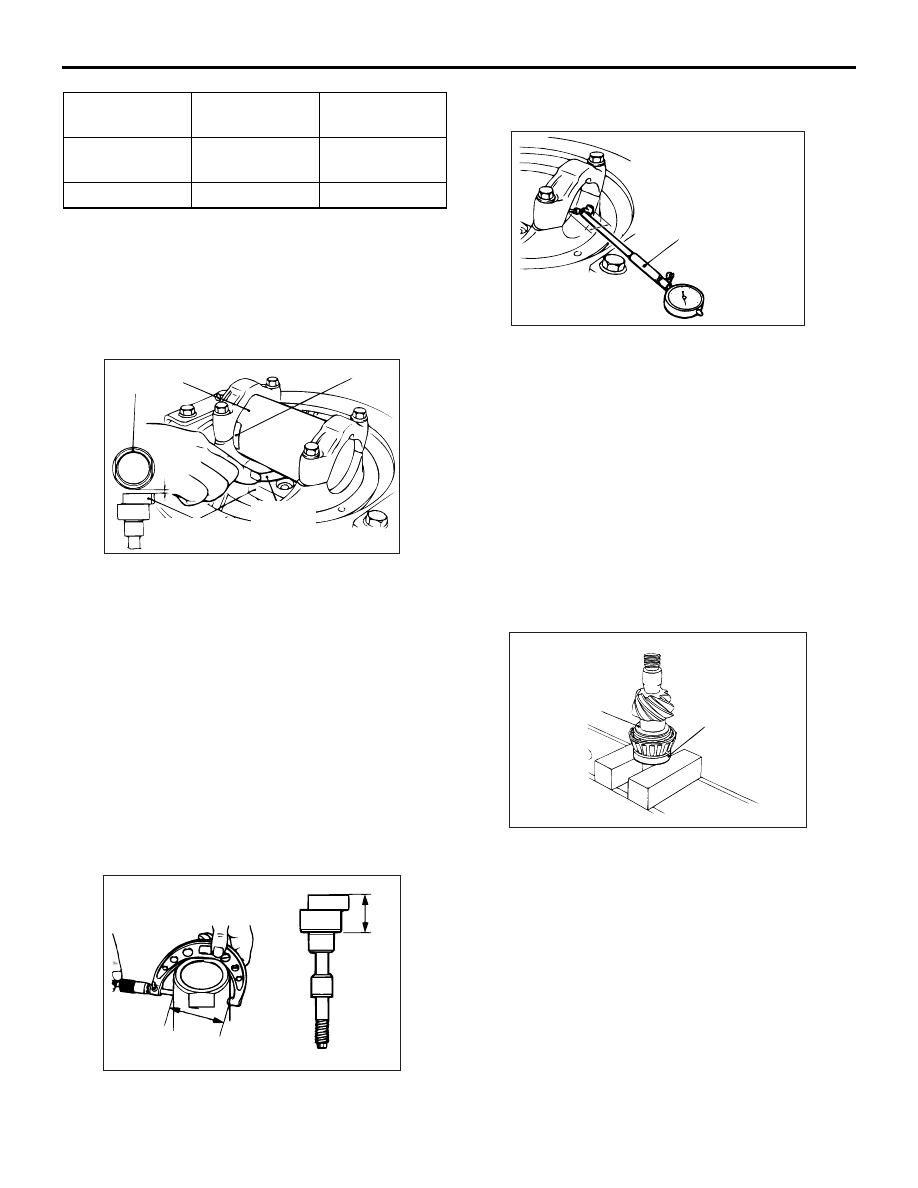

NOTE: Because special tool preload socket

(MB990326) cannot be turned one turn, turn it

several times within the range that it can be

turned; then, after fitting to the bearing, measure

the turning torque.

4. Clean the side bearing hub.

ACX01109 AL

Notch

A

Thickness

gauge

MB990820

(MB990819) or MB991169

MB991170,

MB991534

5. Place the following special tools between the side

bearing hub of the gear carrier, and position the

notch as shown in the illustration. Then tighten

side bearing mounting bolt.

• Cylinder gauge (MB991170) <5A/T or except

vehicles with High power engine>

• Cylinder gauge (MB991534) <Vehicles with High

power engine except 5A/T>

• Pinion [MB990820 (MB990819)] <2WD (except

High rider)>

• Drive pinion gauge attachment (MB991169)

<2WD High rider, 4WD>

6. Use a thickness gauge to measure the clearance

(A) between the special tools.

7. Remove the special tools.

AC102913

C

B

AC

8. Use a micrometer to measure the shown

dimensions (B, C) of special tools.

AC102914

Cylinder gauge

AC

D

9. Install the bearing cap, and then use a cylinder

gauge to measure the inside diameter (D) of the

bearing cap.

10.Calculate thickness (F) of the required drive

pinion rear shim twice by the following formula.

Select a shim which most closely matches this

thickness.

F = A + B + C

− 1/2D − 100.00 mm <2WD

(except High rider)>

F = A + B + C

− 1/2D − 115.00 mm <2WD High

rider, 5A/T or except vehicles with High

power engine>

F = A + B + C

− 1/2D − 120.00 mm <Vehicles

with High power engine except 5A/T>

ACX02428 AE

Drive pinion

rear shim

MB990802

11.Fit the selected drive pinion rear shim(s) to the

drive pinion, and press-fit the drive pinion rear

bearing inner race by using special tool bearing

installer (MB990802).

>>D<< DRIVE PINION PRELOAD ADJUSTMENT

1. Insert the drive pinion into the gear carrier, and

then install the following parts in sequence from

the carrier rear side. Drive pinion spacer, drive

pinion front shim and drive pinion front bearing

inner race, companion flange.

NOTE: Do not install the oil seal.