Mazda Training manual - part 6

Powertrain Engines

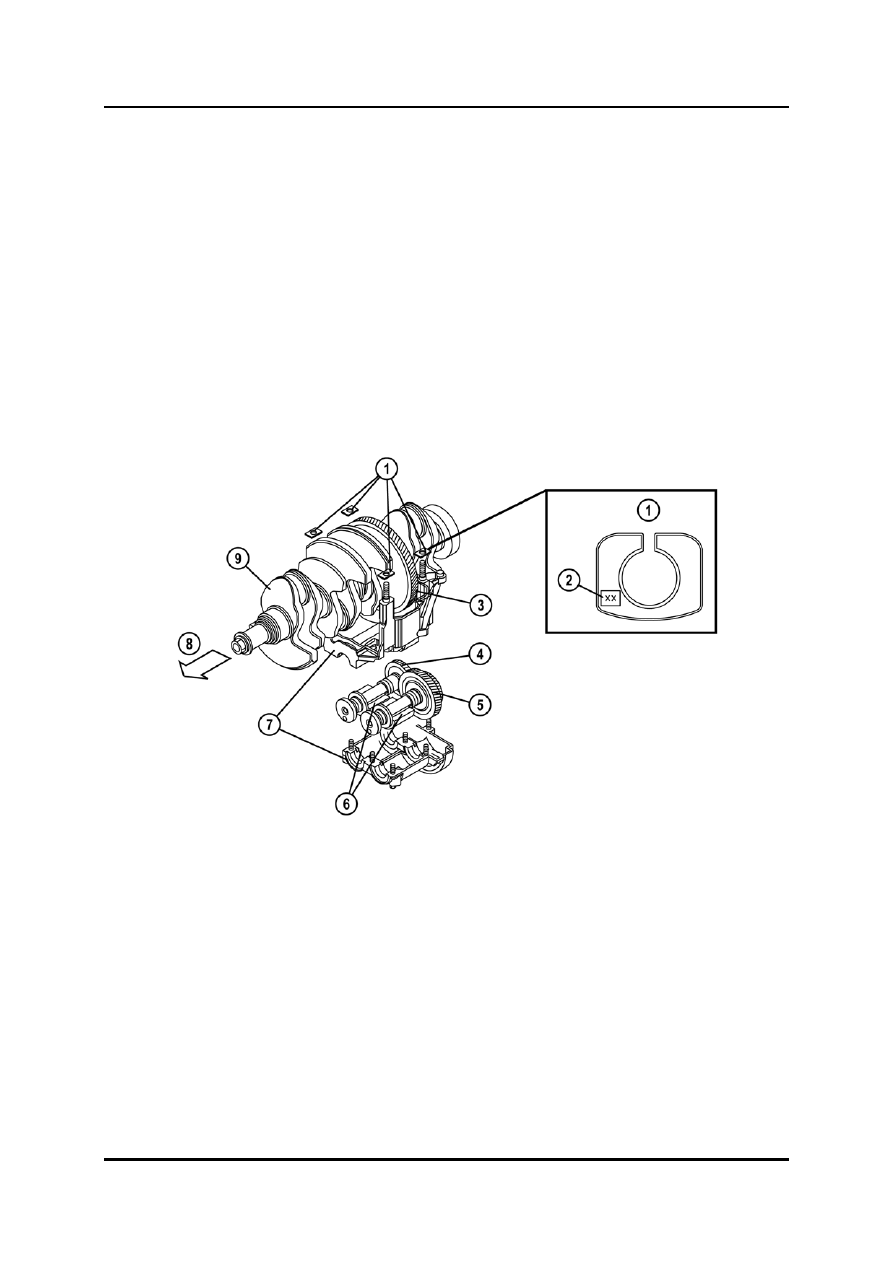

Balancer Shaft Unit

•

The balancer shafts minimize the engine vibrations by rotating at twice the speed of the

crankshaft.

•

The balancer shaft unit features a two-piece housing, which is fixed to the cylinder block

by four bolts.

NOTE: The balancer shaft unit cannot be repaired due to its precise interior construction, i.e.

it must be replaced as a complete unit.

•

If the cylinder block, crankshaft, crankshaft main bearing, or balancer shaft unit have

been replaced, the backlash between the drive gear of the crankshaft and the driven

gear of the balancer shaft unit must be adjusted using shims (refer to the workshop

manual for details).

L1001.4_01006

1

Adjustment shim

6

Counter weights

2

Engraved identification mark

7

Balancer shaft unit housing

3

Drive gear

8

Engine front side

4 Balancer

shaft

no.2

9 Crankshaft

5

Balancer shaft no.1 with driven gear

Curriculum Training

01-11