Mazda engine MZR–CD. Manual - part 12

B–28

ENGINE

VALVE CLEARANCE INSPECTION

AME222412111105

1. Remove the cylinder head cover.

2. Turn the crankshaft and align the timing marks so that the piston of the No.1 or No.4 cylinder is at TDC of

compression.

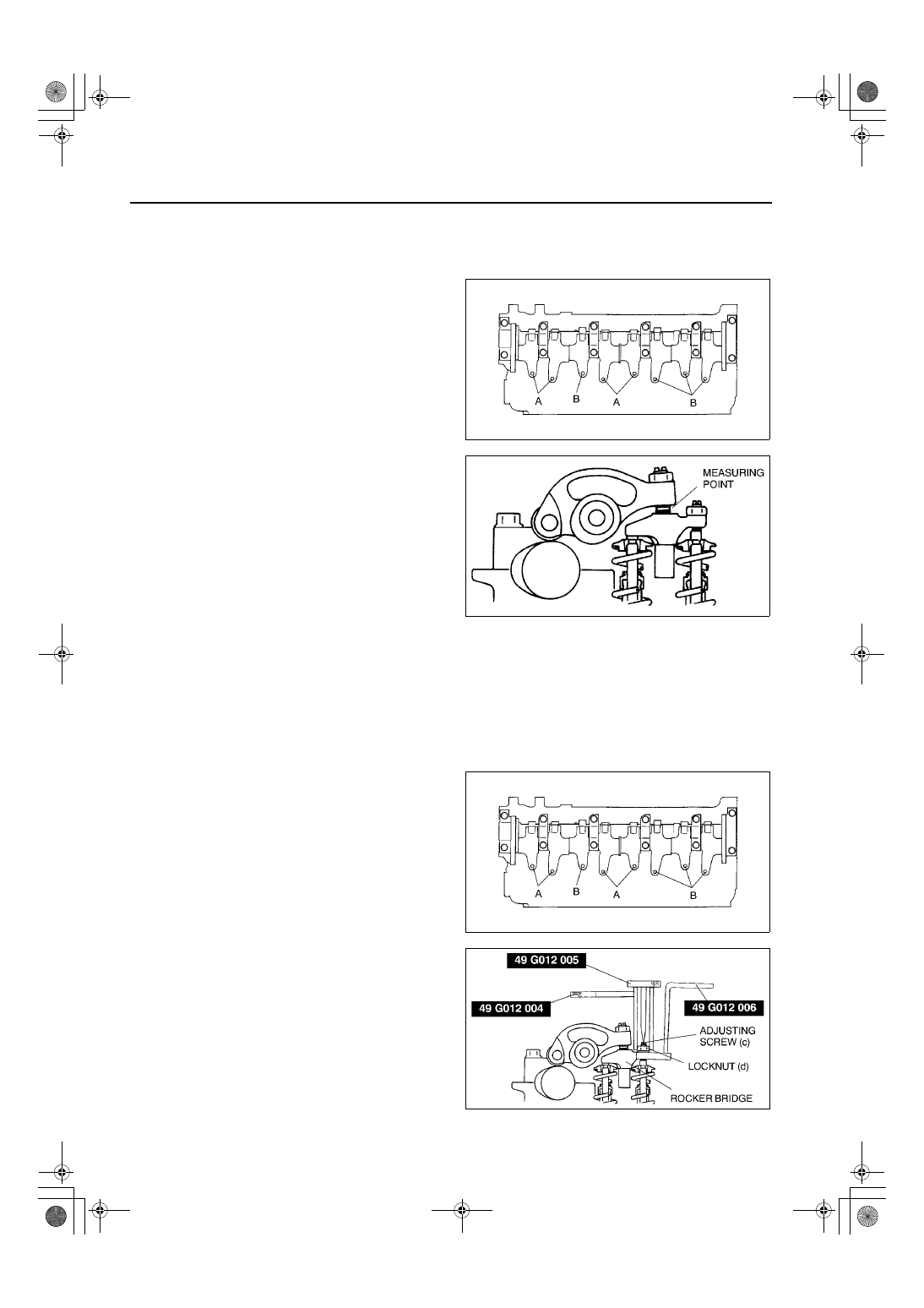

3. Measure the valve clearances A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC of compression.

Standard valve clearance [Engine cold]

IN: 0.12—0.18 mm {0.0048—0.0070 in}

(0.15

±±±±

0.03 mm {0.0059

±±±±

0.0012 in})

EX: 0.32—0.38 mm {0.0126—0.0149 in}

(0.35

±±±±

0.03 mm {0.0138

±±±±

0.0012 in})

4. If the valve clearance is not within the

specification, adjust the valve clearance. (See

5. Turn the crankshaft one full turn and measure the

remaining valve clearances. Adjust the valve

clearance if necessary.

End Of Sie

VALVE CLEARANCE ADJUSTMENT

AME222412111106

1. Remove the injection nozzle bracket.

2. Remove the injection nozzle.

Caution

••••

When removing the injection nozzle bracket, always replace the injection nozzle washer. When

replacing the injection nozzle washer, wipe off any carbon adhering to the nozzle installation

surface of the cylinder head with a clean cloth before installing.

3. Turn the crankshaft clockwise and set the No.1

cylinder to compression TDC.

4. Adjust the valve clearance A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC compression.

(1) Hold the rocker bridge using the SST (49

G012 006).

(2) Loosen the locknut (d) using the SST (49

G012 004), and then turn the adjusting screw

(c) using the SST (49 G012 005) until it is

separated from the valve stem completely.

AME2512E001

AME2512E002

AME2512E001

AME2512E003