Mazda CX 7. Manual - part 250

SYMPTOM TROUBLESHOOTING [AW6A-EL, AW6AX-EL]

05-03–19

05-03

End Of Sie

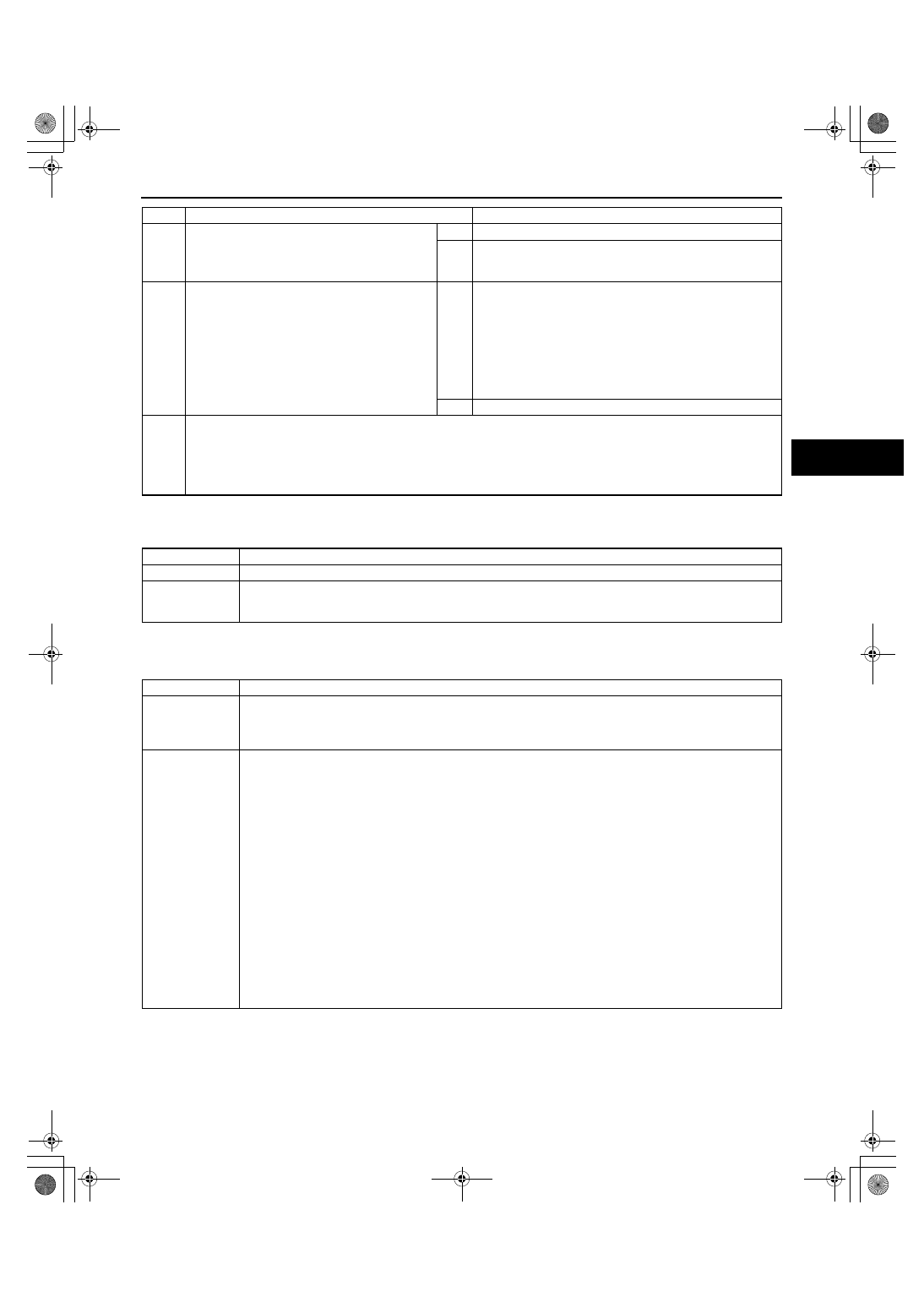

NO.13 NO KICKDOWN[AW6A-EL, AW6AX-EL]

id050310801800

End Of Sie

NO.14 ENGINE FLARES UP OR SLIPS WHEN UPSHIFTING OR DOWNSHIFTING[AW6A-EL, AW6AX-EL]

id050310801900

3

• Inspect the line pressure control solenoid.

(See 05-17-20 SOLENOID VALVE

INSPECTION[AW6A-EL, AW6AX-EL].)

• Is the line pressure control solenoid normal?

Yes

Go to the next step.

No

Replace the control valve body.

(See 05-17-38 CONTROL VALVE BODY REMOVAL/

INSTALLATION[AW6A-EL, AW6AX-EL].)

4

• Remove the torque converter.

(See 05-17-46 TORQUE CONVERTER

REMOVAL/INSTALLATION[AW6A-EL,

AW6AX-EL].)

• Inspect the torque converter.

• Is the torque converter normal?

Yes

Inspect the ATF condition.

• If a large amount of metal specks are found, replace the

transaxle.

(See 05-17-29 AUTOMATIC TRANSAXLE REMOVAL/

INSTALLATION[AW6A-EL, AW6AX-EL].)

• If a large amount of metal specks are not found, replace

the control valve body.

(See 05-17-38 CONTROL VALVE BODY REMOVAL/

INSTALLATION[AW6A-EL, AW6AX-EL].)

No

Replace the torque converter.

5

• Verify test results.

— If normal, return to the diagnostic index to service any additional symptoms.

— If malfunction remains, inspect the related Service Bulletins and/or On-line Repair Information and perform

repair or diagnosis.

• If the vehicle is repaired, troubleshooting completed.

• If the vehicle is not repaired or additional diagnostic information is not available, replace the TCM.

STEP

INSPECTION

ACTION

13

No kickdown

DESCRIPTION

• Does not downshift when accelerator pedal is fully depressed within kickdown range.

POSSIBLE

CAUSE

• If transaxle does not downshift though shifting is normal, the malfunction is in the accelerator pedal

position sensor and accelerator pedal position sensor circuits (including sensor GND, sensor wiring

harness and connector).

14

Engine flares up or slips when upshifting or downshifting

DESCRIPTION

• When the accelerator pedal is depressed for acceleration from standstill, engine speed increases but

the vehicle speed increases slowly.

• When the accelerator pedal is depressed while driving, engine speed increases but the vehicle speed

does not.

POSSIBLE

CAUSE

• There is clutch slippage because the clutch is stuck or the line pressure is low.

— Clutch stuck, slippage (C1 clutch, C2 clutch, C3 clutch, B1 brake)

• Line pressure low

• Incorrect accelerator opening signal

• VSS malfunction

• Input/turbine speed sensor malfunction

• Sensor GND malfunction

• Shift solenoid C malfunction

• Shift solenoid D malfunction

• Shift solenoid E malfunction

• Line pressure control solenoid malfunction

• TCC control solenoid malfunction

• Shift solenoid F malfunction

• Body GND malfunction

• Control valve body malfunction

Note

• Before following the troubleshooting steps, make sure that the Automatic Transaxle On-Board

Diagnostic and Automatic Transaxle Basic Inspection are conducted. (See 05-03-3 BASIC

INSPECTION[AW6A-EL, AW6AX-EL].)

1871-1U-06B(05-03).fm 19 ページ 2006年3月15日 水曜日 午前11時19分