Mazda CX 7. Manual - part 194

ALL WHEEL DRIVE (AWD)

03-19–7

03-19

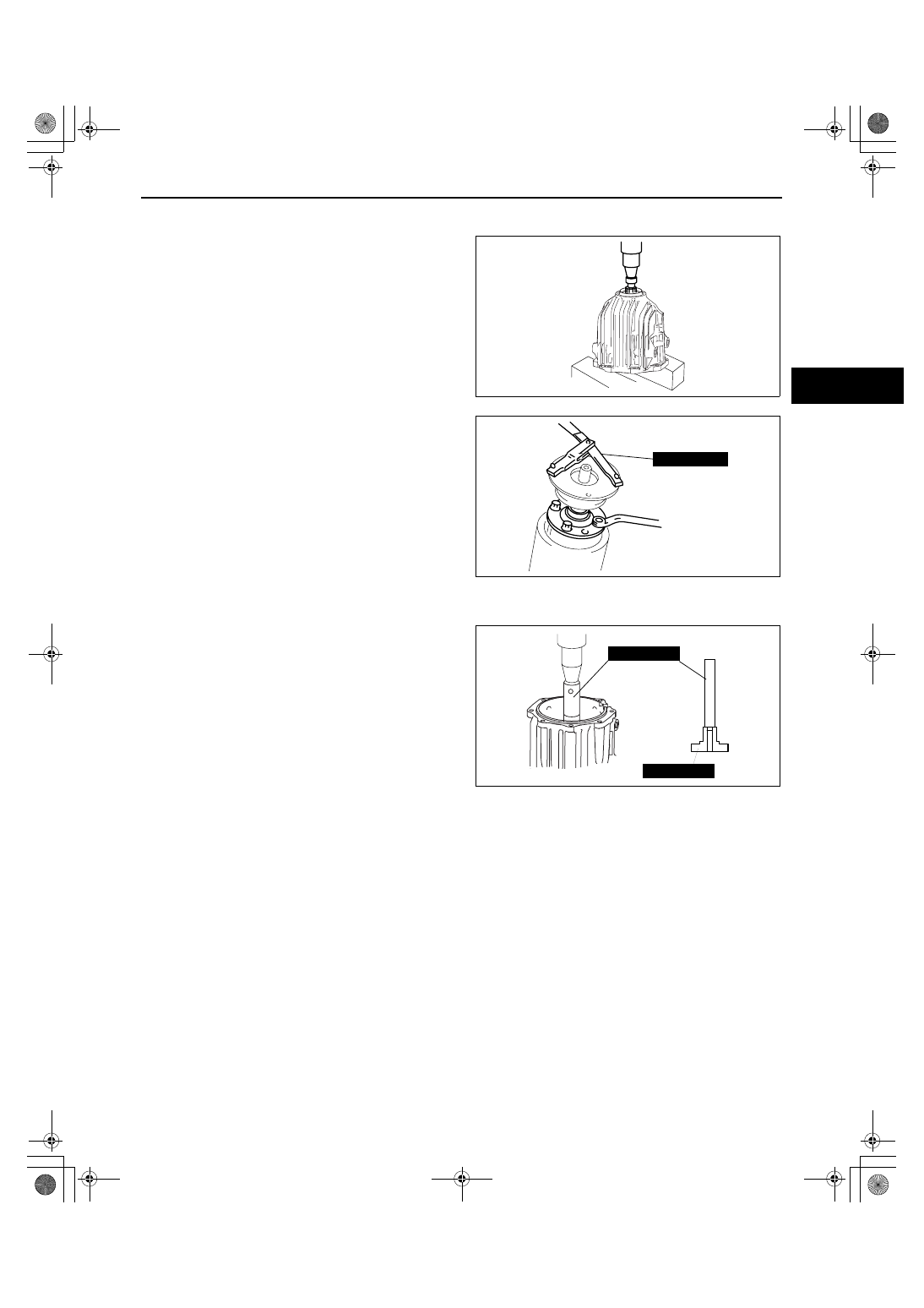

Output Shaft Disassembly Note

1. Remove the coupling unit from the SST.

2. Install the coupling unit to the press as shown,

and remove the output shaft together with the

coupling unit.

3. Install the companion flange to the output shaft.

4. Secure the companion flange using the SST, and

remove the bolts.

5. Remove the output shaft.

Bearing Disassembly Note

1. Remove the bearing using the SSTs and a press.

Substitution SST

• 49 S033 108

Outer diameter: 33— 55 mm {1.30— 2.16 in}

Height: 155 mm {6.10 in} or more

End Of Sie

acxuuw00001448

49 S120 710

acxuuw00001449

49 M005 797

49 S033 108

acxuuw00001450

1871-1U-06B(03-19).fm 7 ページ 2006年3月15日 水曜日 午前11時9分