Mazda Protege 5. Manual - part 210

CONVENTIONAL BRAKE SYSTEM

04–11–9

04–11

3. Invert the SST used in Step 1 and place it on the

power brake unit.

4. Measure the clearance between the end of the

SST and the push rod of the power brake unit.

•

If it is not 0.1—0.4 mm {0.004—0.016 in},

loosen the push rod locknut and turn the push

rod to adjust it using the SSTs.

End Of Sie

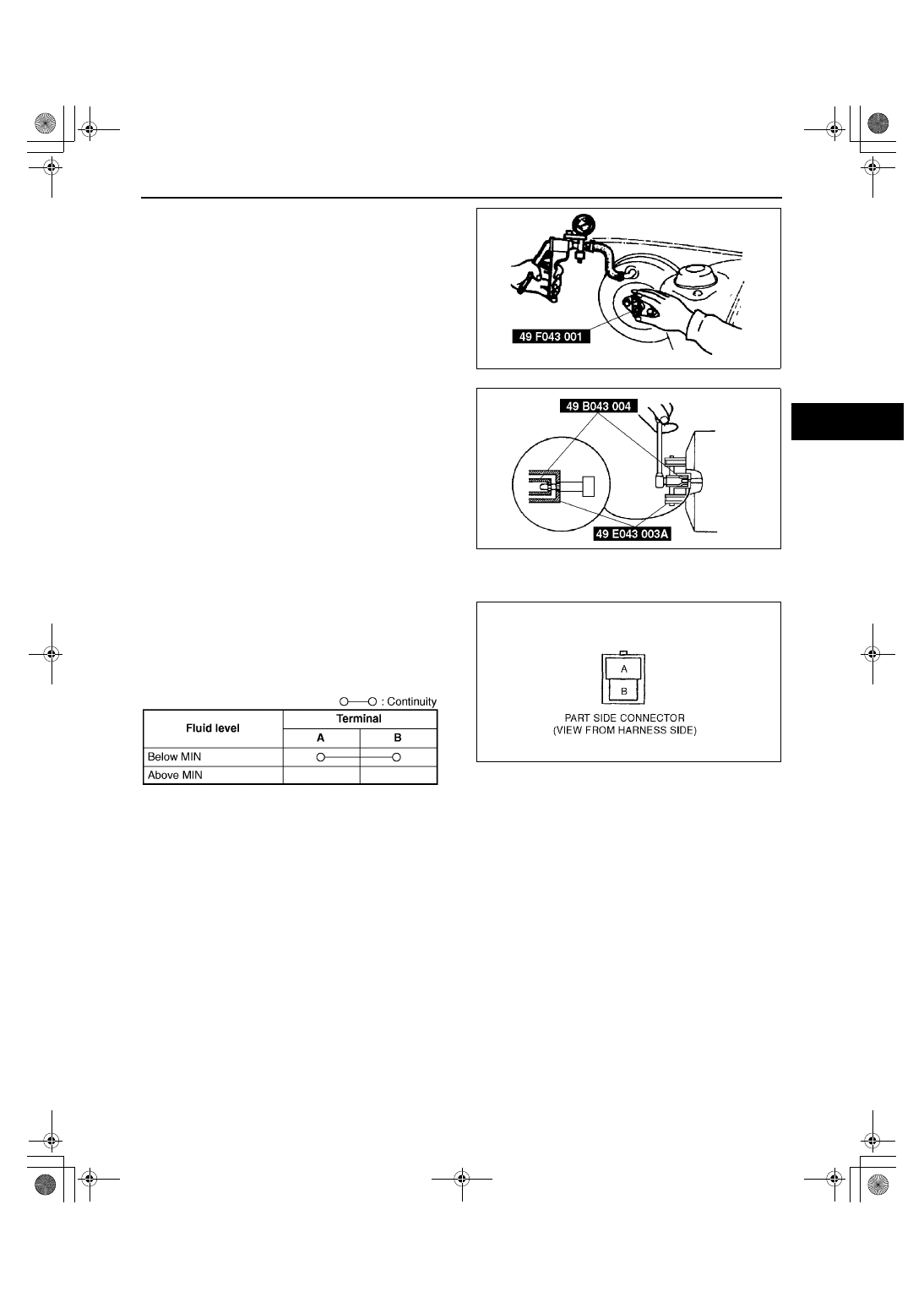

FLUID LEVEL SENSOR INSPECTION

A3U041143540W01

1. Disconnect the sensor connector.

2. Connect an ohmmeter to the connector.

3. Starting with the fluid level above MIN, verify that

there is no continuity.

4. Remove the brake fluid and verify that there is

continuity when the level is below MIN.

•

If not as specified, replace the sensor.

End Of Sie

X3U411WAB

X3U411WAC

Y3U411WA1

X3U411WAD

1712-1U-01G(04-11).fm 9 ページ 2001年6月29日 金曜日 午前10時3分