Mazda Protege 5. Manual - part 149

FUEL SYSTEM

01–14–21

01–14

15. Reconnect the fuel main hose to the fuel main pipe until a click is heard.

16. Pull the quick release connector by hand and verify that it is installed securely.

17. Complete the “AFTER REPAIR PROCEDURE”. (See 01–14–5 AFTER REPAIR PROCEDURE.)

End Of Sie

FUEL FILTER (HIGH-PRESSURE) REMOVAL/INSTALLATION

A3U011434801W01

1. Remove and install the fuel filter (high-pressure). (See 01–14–15 FUEL PUMP UNIT DISASSEMBLY/

ASSEMBLY.)

End Of Sie

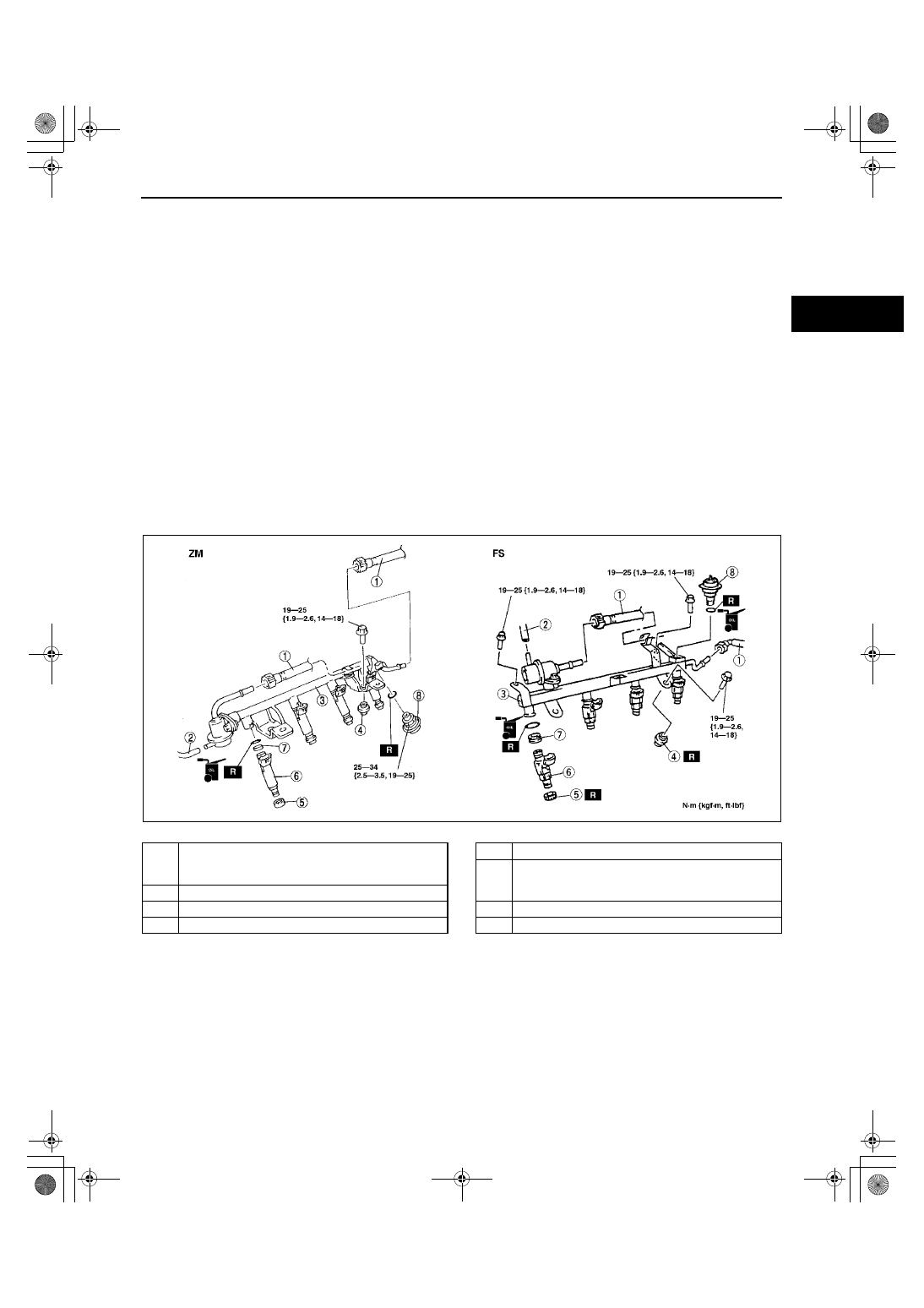

FUEL INJECTOR REMOVAL/INSTALLATION

A3U011413250W01

Caution

••••

Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

1. Complete the “BEFORE REPAIR PROCEDURE”. (See 01–14–4 BEFORE REPAIR PROCEDURE.)

2. Disconnect the battery negative cable.

3. Remove the accelerator cable bracket. (See 01–13A–5 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION

[ZM].) (See 01–13B–6 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [FS].)

4. Disconnect the fuel injector connectors and remove the harness from the fuel distributor.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”. (See 01–14–5 AFTER REPAIR PROCEDURE.)

.

Z3U0114W995

1

Plastic fuel hose

(See 01–14–22 Plastic Fuel Hose Removal Note)

(See 01–14–23 Plastic Fuel Hose Installation Note)

2

Vacuum hose

3

Fuel distributor

4

Fuel distributor insulator

5

Fuel injector insulator

6

Fuel injector

(See 01–14–23 Fuel Injector Installation Note (FS

only))

7

Grommet

8

Pulsation damper

1712-1U-01G(01-14).fm 21 ページ 2001年6月29日 金曜日 午前9時43分