Engine JAC HFC4DA1-2C. Manual - part 15

Maintenance manual for sunray hfc4da1-2c china-IV diesel engines

59

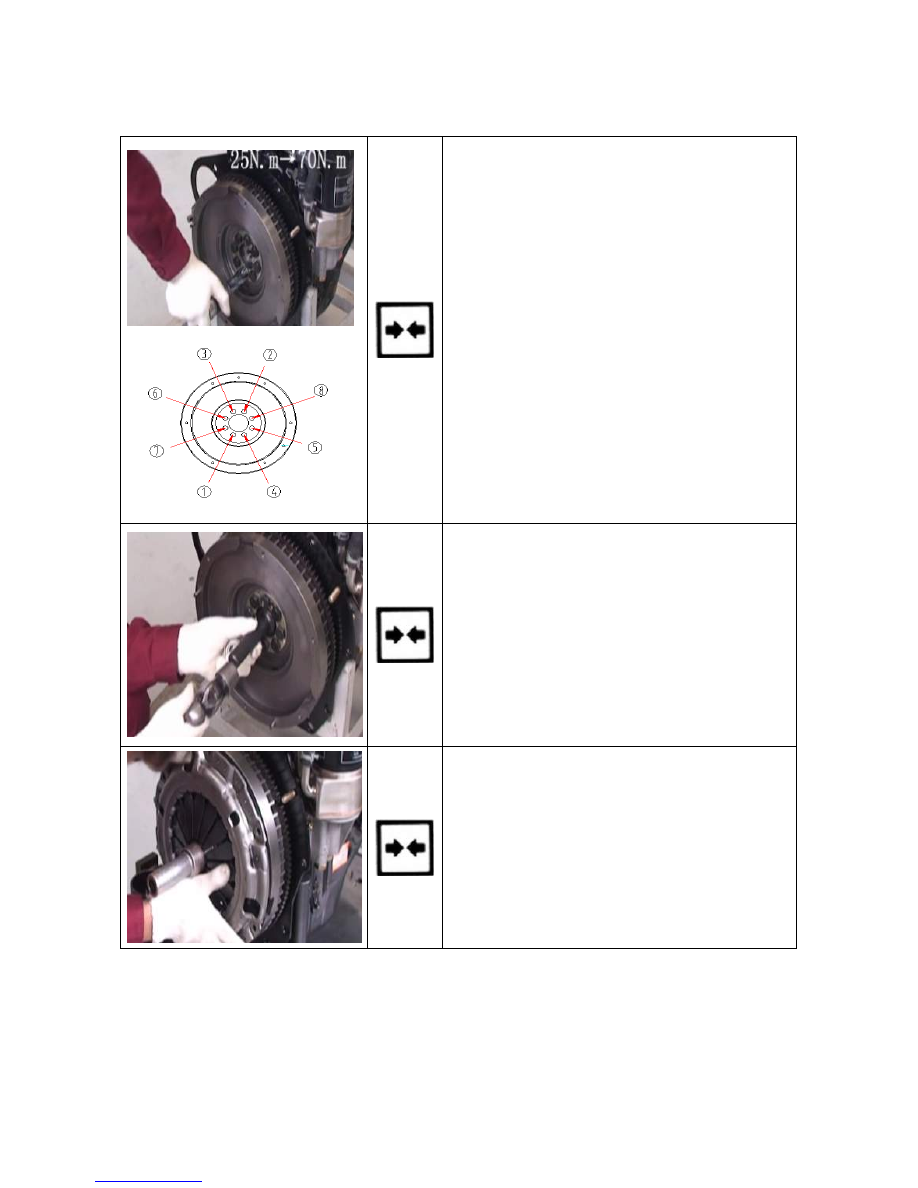

c. Install the flywheel.

d. Install the flywheel fixing gasket and install and

pre-tighten the fixing bolts of flywheel.

e. As per the specified sequence, tighten the fixing bolts

of flywheel to 25N.m→70N.m →140N.m by steps,

in order to prevent the occurrence of false tightening

torque. This tightening torque is really high and will

easily lead to thread failure of the bolts.

f. Install the lubricated guide ball bearings into the

installation jig and knock with steel hammer

uniformly into the rear end of crankshaft.

g. Insert the clutch guide into the driven disc and install

to the rear end of flywheel. Install the clutch cover

and install and tighten the fixing bolts of clutch

cover.