Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 848

6E–416

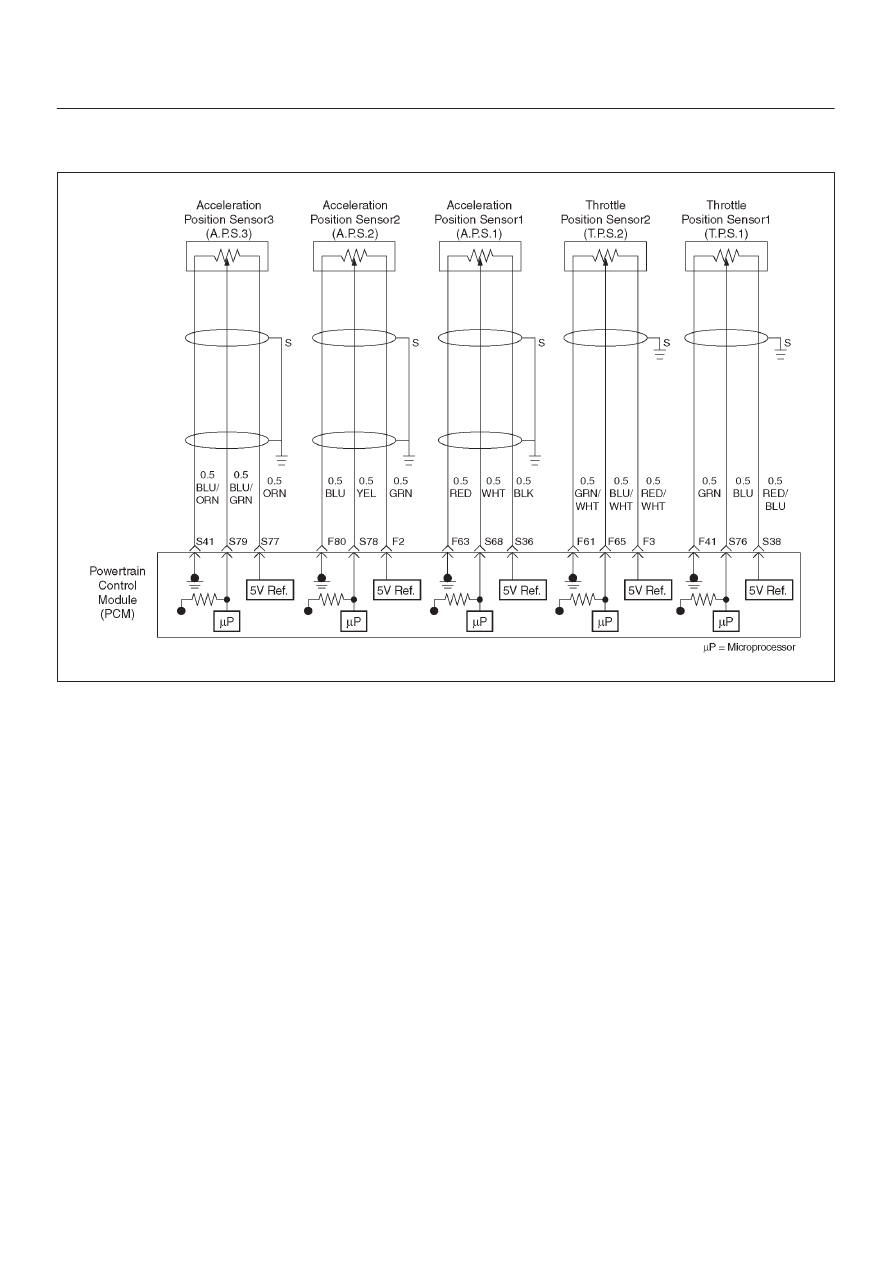

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis Truble Code(DTC)

P1221 TPS1 – TPS2 correlation(Circuit Performance)

D06RY00157

Circuit Description

D

The powertrain control module (PCM) controls engine

speed by adjusting the position of the throttle control

valve (DC motor). The throttle motor is a DC motor

driven by one coil. The PCM applies current to DC

motor coil in steps (%) to adjustment the valve into a

passage in the throttle body to air flow.

This method allows highly accurate control of engine

speed and quick response to changes in engine

load.

D

The acceleration position (AP) sensor circuit provides

a voltage signal relative to acceleration pedal angle.

The acceleration pedal angle (AP1) will vary about

13% at idle position to about 87% at open

throttle(WOT).

APS signal is used to determine which DC will

adjusting throttle position.

After the APS signal has been processed by the

PCM, it will command DC motor to allow a move of

throttle position.

D

Acceleration pedal – Check for objects blocking the AP

sensor or pedal arm with spring, and excessive

deposits in the acceleration pedal arm and on the

acceleration pedal.

Diagnostic Aids

D

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness. Inspect the PCM harness and

connector for improper mating, broken locks,

improperly formed or damaged terminals, poor

terminal-to-wire connection, and damaged harness.

D

Throttle body – Check for objects blocking the DC

motor or throttle bore, excessive deposits in the ETC

passage and on the valve spring, and excessive

deposits in the throttle bore and on the throttle valve

plate.