Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 783

6E–156

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0118 – ECT Sensor Circuit High Voltage

(Cont'd)

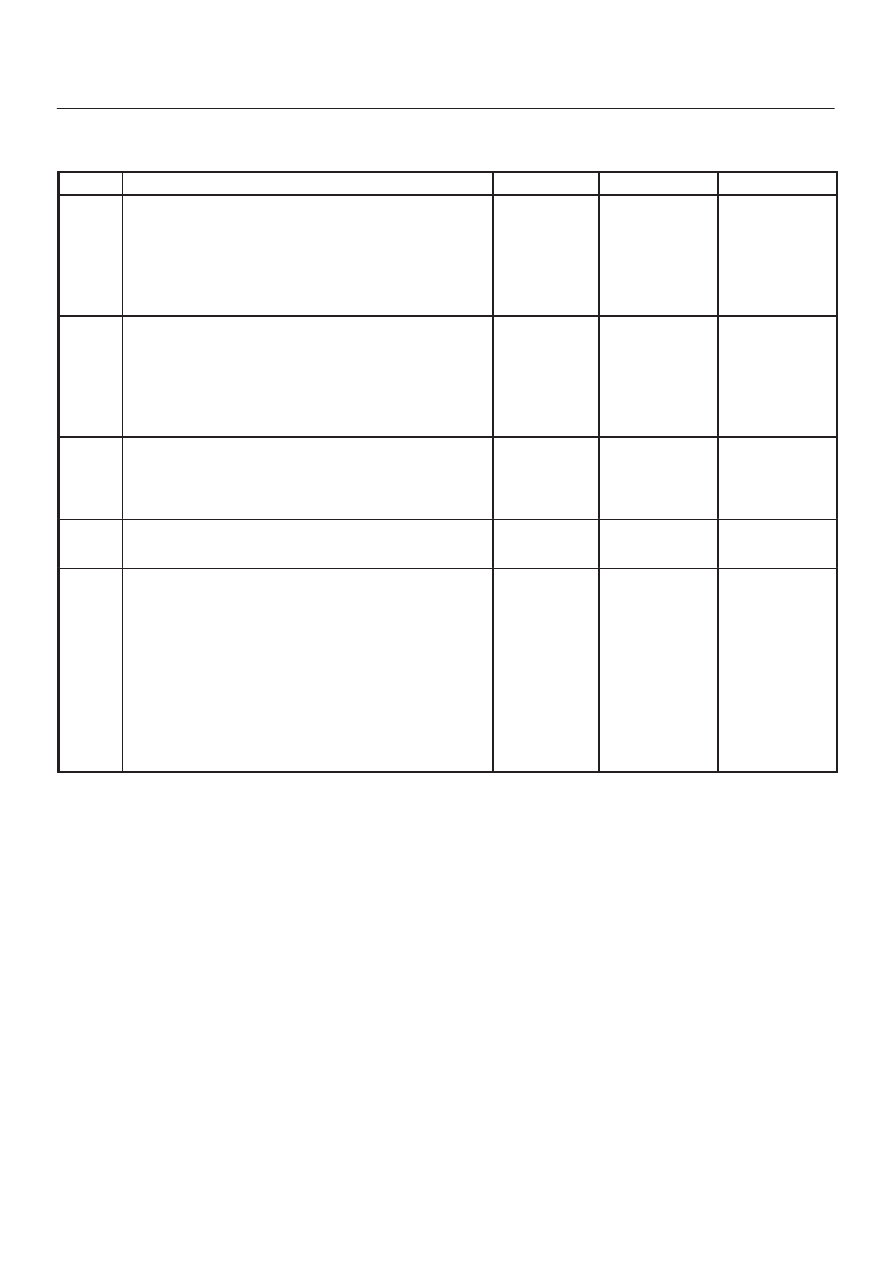

Step

No

Yes

Value(s)

Action

7

1. Ignition “OFF”.

2. Disconnect the PCM, and check the ECT sensor

ground circuit for an open.

3. If the ECT sensor ground circuit is open, repair it as

necessary.

Was the ECT sensor ground circuit open?

—

Verify repair

Go to

Step 9

8

1. Ignition “OFF”.

2. Disconnect the PCM, and check the ECT signal

circuit for an open.

3. If the ECT sensor signal circuit is open, repair it as

necessary.

Was the ECT signal circuit open?

—

Verify repair

Go to

Step 9

9

Check for a poor sensor ground or ECT signal circuit

terminal connection at the PCM and replace

terminal(s) if necessary.

Did any of the terminals need to be replaced?

—

Verify repair

Go to

Step 11

10

Replace the ECT sensor.

Is the action complete?

—

Verify repair

—

11

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to

On-Vehicle Service in

Powertrain Control Module and Sensors for

procedures.

And also refer to latest Service Bulletin.

Check to see if the Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Verify repair

—