Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 743

6D3–22 STARTING AND CHARGING SYSTEM

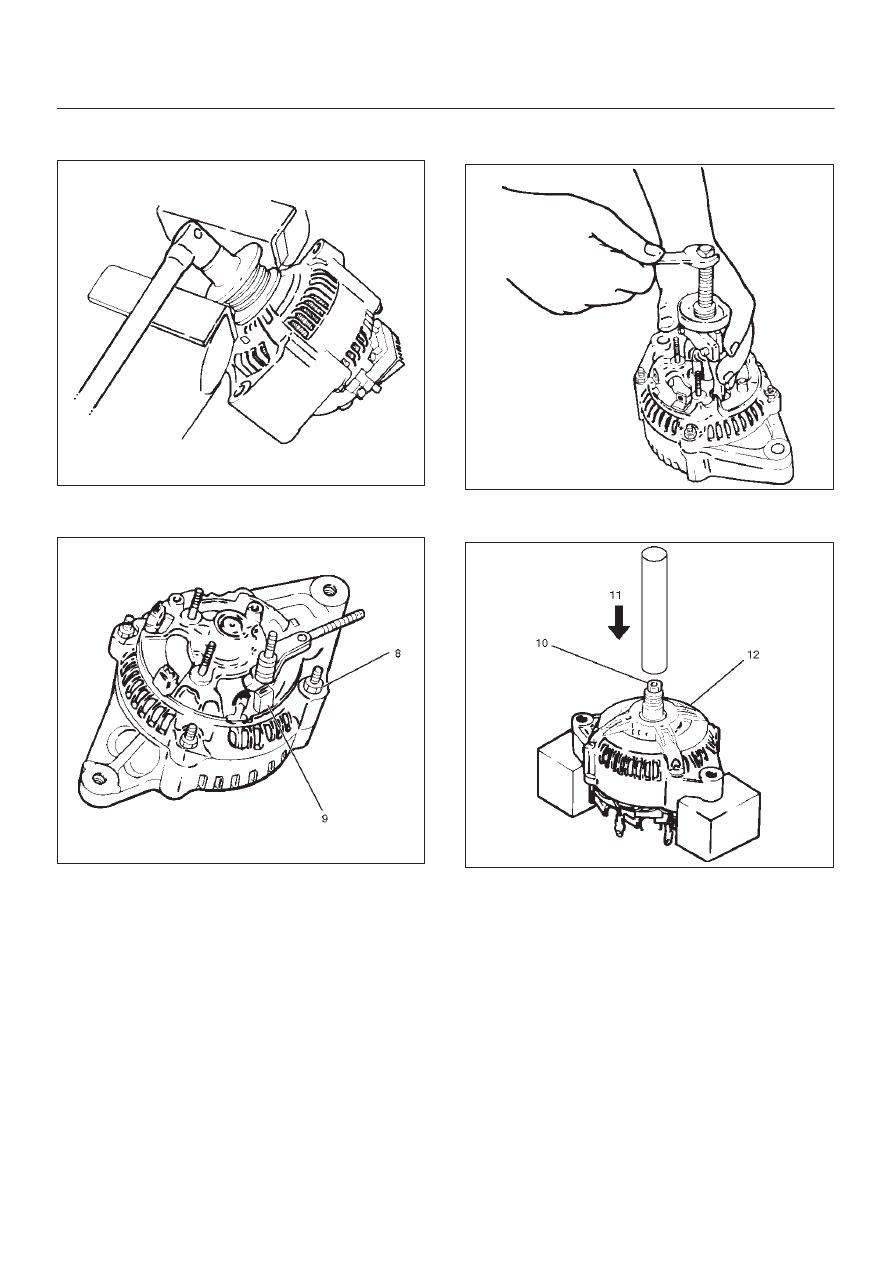

6. Secure the pulley directly in the vise between two

copper plates, and remove the nut and pulley.

066RS010

7. Remove four nuts(8) that secure the front cover

assembly and rear end cover, and an insulator(9).

066RW005

8. Use the puller to remove the rear end cover.

9. Rotor assembly

066RS012

10. Pull the rotor assembly(10) off the front cover

assembly(12) using a bench press(11).

066RW006