Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 740

6D3–10 STARTING AND CHARGING SYSTEM

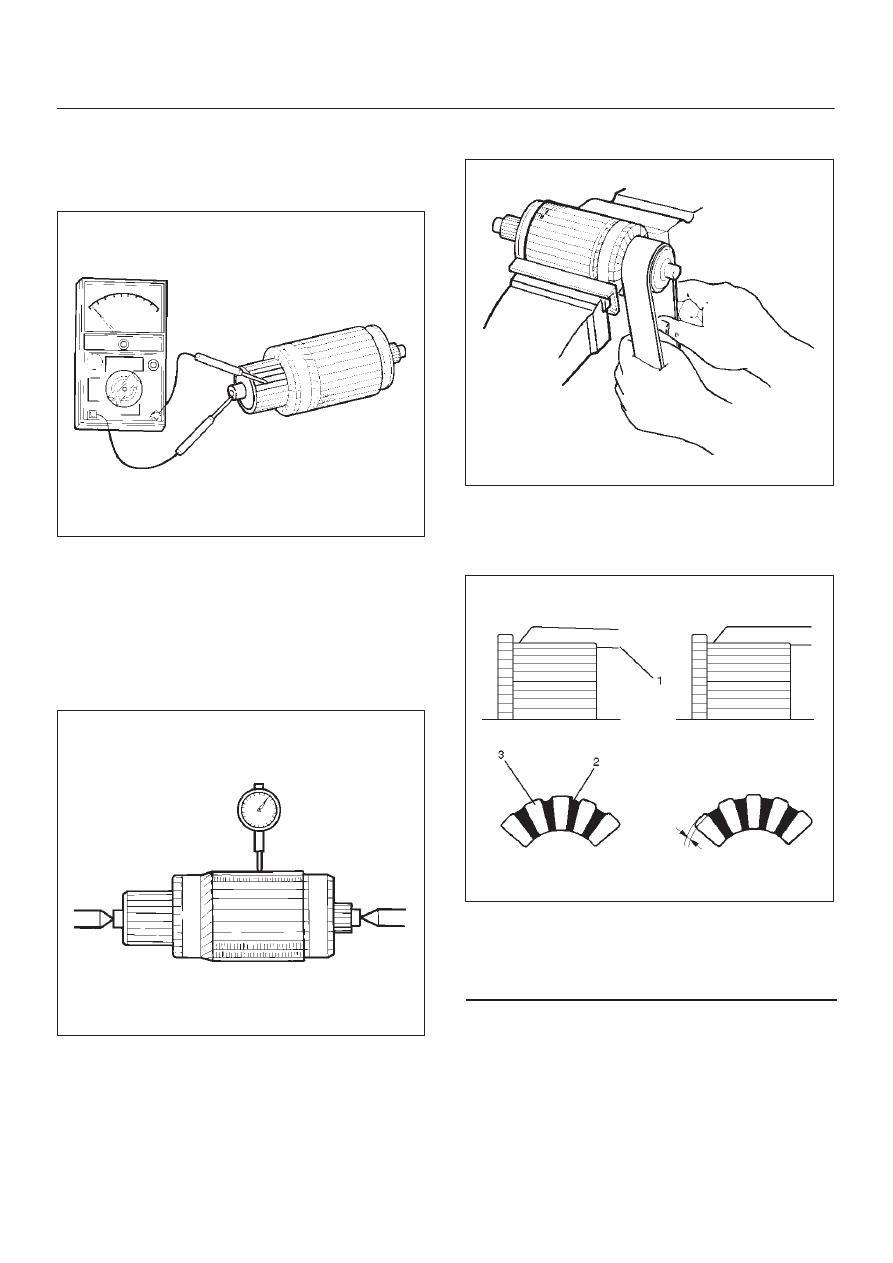

Check for continuity between commutator and shaft.

Also, check for continuity between commutator and

armature core,armature core and shaft. Replace

commutator if there is continuity (i.e., internally

grounded).

065RS016

Measure runout of armature core and commutator with a

dial gauge. Repair or replace, if it exceeds the limit.

Armature

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

Commutator

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

065RS017

Polish the commutator surface with sandpaper #500 to

#600 if it is rough.

065RW012

Measure the depth of insulator in commutator. Repair, if it

is below the limit.

Standard: 0.5 mm to 0.8 mm (0.02 in to 0.03 in)

Limit: 0.2 mm (0.008 in)

065RW013

Legend

(1) Steel Saw

(2) Insulator

(3) Commutator Segments