Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 710

6A–21

ENGINE MECHANICAL

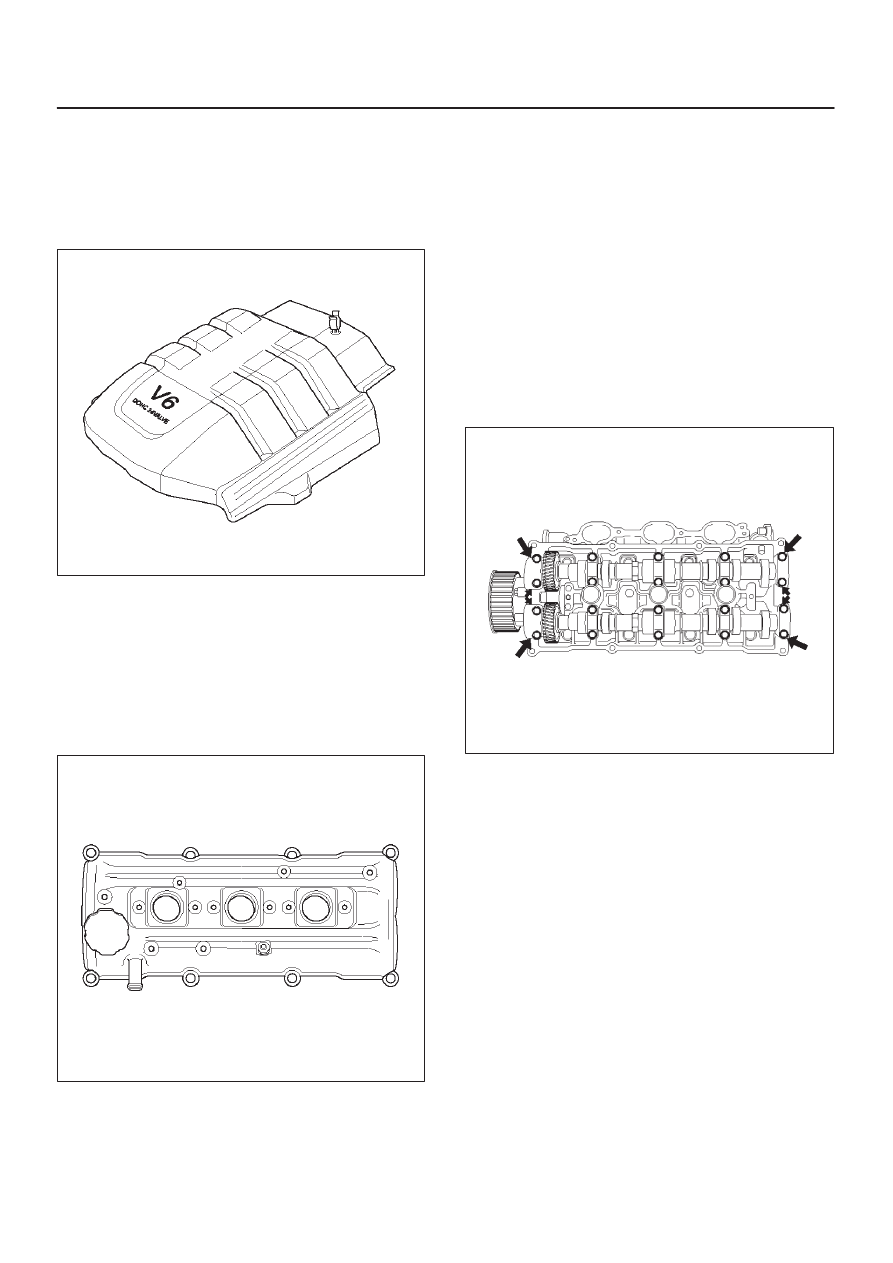

Cylinder Head Cover RH

Removal

1. Disconnect battery ground cable.

2. Remove engine cover from the dowels on the

common chamber.

F06RY001

3. Disconnect ventilation hose from cylinder head cover.

4. Disconnect three ignition coil connectors from ignition

coils and remove harness bracket bolts on cylinder

head cover then remove ignition coil fixing bolts on

ignition coils and remove ignition coils.

5. Disconnect fuel injector harness connector then

remove fuel injector harness bracket bolt.

6. Remove eight fixing bolts then the cylinder head

cover.

010RW002

Installation

1. Install cylinder head cover.

D

Clean the sealing surface of cylinder head and

cylinder head cover to remove oil and sealing

materials completely.

Apply sealant (TB-1207B or equivalent) bead

(diameter 2-3 mm) at eight places of arched areas

of camshaft bracket on front and rear sides.

D

The cylinder head cover must be installed within 5

minutes after sealant application to prevent

premature hardening of sealant.

D

Tighten bolts to the specified torque.

Torque : 9 N·m (78 lb in)

014RW019

2. Tighten fuel injector harness bracket bolts to

specified torque then reconnect fuel injector harness

connector.

Torque : 9 N·m (78 lb ft)

3. Connect ignition coil connector and tighten ignition

coil fixing bolts to specified torque.

Torque : 4 N·m (35 lb in)

4. Connect ventilation hose to cylinder head.

5. Install engine cover mating with the dowels.