Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 597

3E–10

WHEEL AND TIRE SYSTEM

Tire

Tire Replacement

When replacement is necessary, the original metric the

size should be used. Most metric tire sizes do not have

exact corresponding alphanumeric tire sizes. It is

recommended that new tires be installed in pairs on the

same axle. If necessary to replace only one tire, it should

be paired with tire having the most tread, to equalize

braking traction.

CAUTION: Do not mix different types of tires such

as radial, bias and bias-belted tires except in

emergencies, because vehicle handling may be

seriously affected and may result in loss of control.

Tire Dismounting

Remove valve cap on valve step and deflate the tire. Then

use a tire changing machine to mount or dismount tires.

Follow the equipment manufacturer’s instruction. Do not

use hand tools or tire lever alone to change tires as they

may damage the tire beads or wheel rim.

Tire Mounting

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, and light rust.

Before mounting a tire, the bead area should be well

lubricated with an approved tire lubricant.

After mounting, inflate the tire to 196kPa (28 psi) so that

beads are completely seated. Inflate the air to specified

pressure and install valve cap to the stem.

WARNING: NEVER STAND OVER TIRE WHEN

INFLATING. BEAD MAY BREAK WHEN BEAD SNAPS

OVER RIM’S SAFETY HUMP AND CAUSE SERIOUS

PERSONAL INJURY.

NEVER EXCEED 240 KPA (35 PSI) PRESSURE WHEN

INFLATING. IF 240 KPA (35 PSI) PRESSURE WILL

NOT SEAT BEADS, DEFLATE, RE-LUBRICATE AND

RE-INFLATE. OVER INFLATION MAY CAUSE THE

BEAD TO BREAK AND CAUSE SERIOUS PERSONAL

INJURY.

Tire Repair

There are many different materials on the market used to

repair tires.

Manufacturers have published detailed instructions on

how and when to repair tires. These instructions can be

obtained from the tire manufacturer if they are not

included with the repair kit.

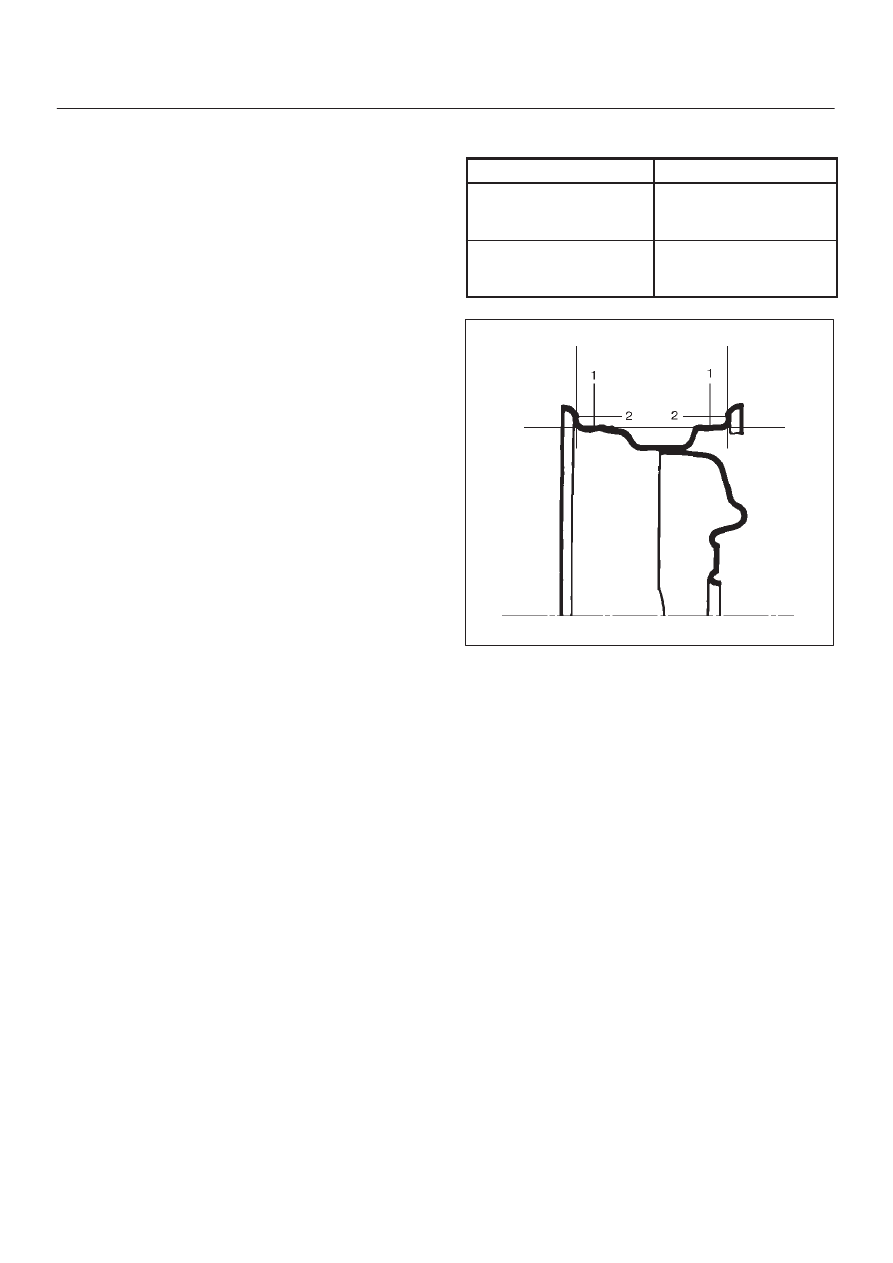

Wheel Inspection

Damaged wheels and wheels with excessive run-out

must be replaced.

Wheel run out at rim (Base on hub Bore):

Steel

Aluminum

1– Vertical play:

Less than

1.5 mm (0.059 in)

1– Vertical play:

Less than

0.7 mm (0.028 in)

2– Horizontal play:

Less than

1.5 mm (0.059 in)

2– Horizontal play:

Less than

0.7 mm (0.028 in)

480RS012

General Balance Procedure

Deposits of mud, etc. must be cleaned from the inside of

the rim.

The tire should be inspected for the following: match

mount paint marks, bent rims, bulges, irregular tire wear,

proper wheel size and inflation pressure. Then balance

according to the equipment manufacturer’s

recommendations.

There are two types of wheel and tire balance.

Static balance is the equal distribution of weight around

the wheel.

Assemblies that are statically unbalanced cause a

bouncing action called tramp. This condition will

eventually cause uneven tire wear.