Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 577

POWER ASSISTED SYSTEM

2A–37

Removal

1. Remove wheel and tire assembly. Refer to Wheel

Replacement in Suspension section.

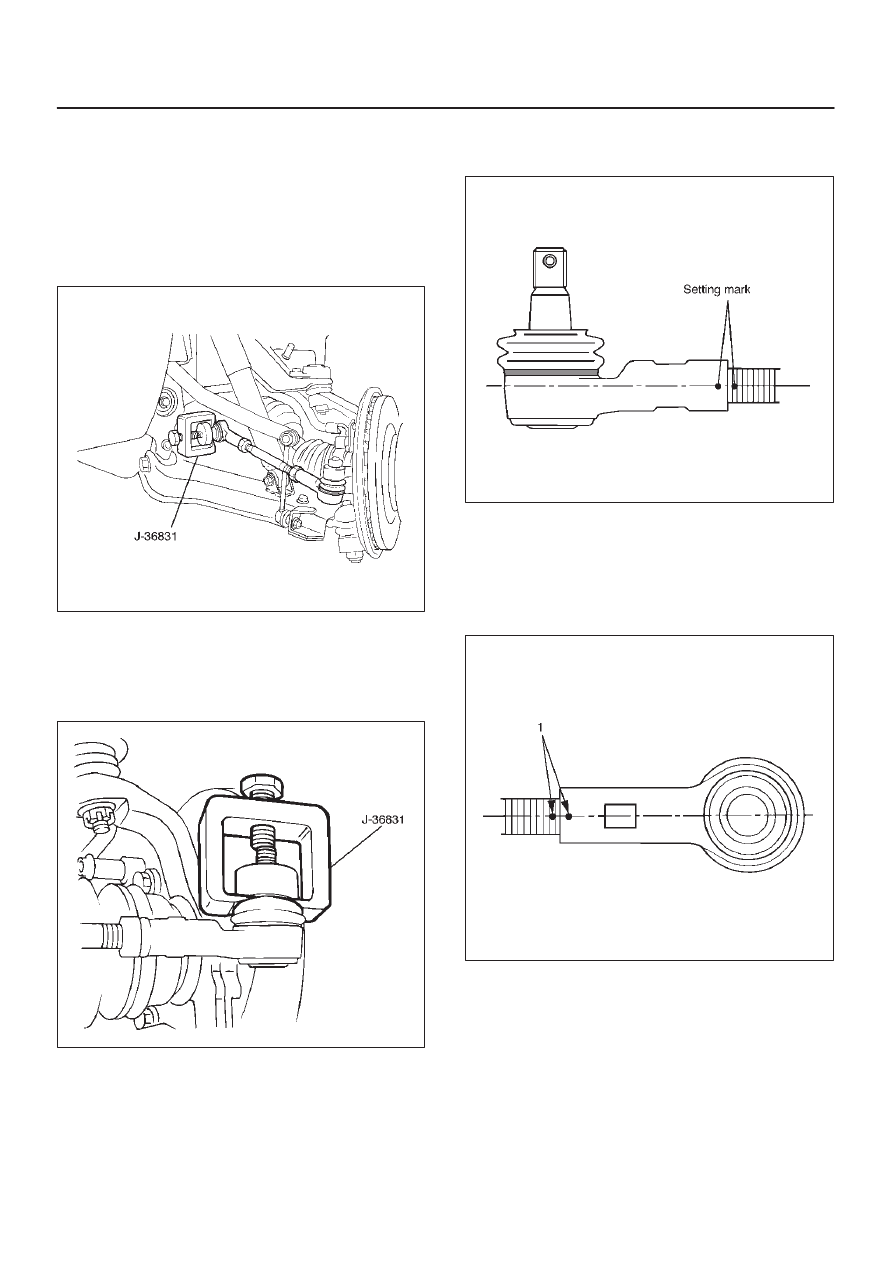

2. Remove nut and cotter pin, then use remover

J–36831 to disconnect outer track rod assembly at

the center track rod.

CAUTION: Be careful not to damage the ball joint

boot.

433RS009

3. Remove nut and cotter pin then use remover J–36831

to remove outer track rod assembly from the knuckle

arm.

CAUTION: Be careful not to damage the ball joint

boot.

433RS013

4. Remove outer lock nut.

5. Apply setting marks (1) to ensure reassembly of the

parts in their original position, then remove outer rod

end assembly.

433RS014

6. Remove inner lock nut.

NOTE: For either outer rod, the screw on the right side of

the vehicle is threaded counterclockwise.

7. Apply setting marks (1) to ensure reassembly of the

parts in their original position, then remove inner rod

end.

433RS015

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion, bending, deteriorations or any other

abnormal condition are found through inspection.

Check the following parts:

D

Rod end assembly

D

Ball joint (Boot, screws and tapered surfaces)