Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 507

SUPPLEMENTAL RESTRAINT SYSTEM

9J–11

Air Bag Assembly Shipping Procedure For

Live (Undeployed) Air Bag Assemblies

Service personnel should refer to the latest Service

Bulletins for proper SRS air bag assembly shipping

procedures.

Deployed Air Bag Assembly

You should wear gloves and safety glasses. After the air

bag assembly has been deployed, the surface of the air

bag may contain a powdery residue. This powder

consists primarily of cornstarch (used to lubricate the bag

as it inflates) and by products of the chemical reaction.

Sodium hydroxide dust (similar to lye soap) is produced

as a by product of the deployment reaction. The sodium

hydroxide then quickly reacts with atmospheric moisture

and is converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikely that

sodium hydroxide will be present.

Air Bag Assembly Scrapping Procedure

During the course of a vehicle’s useful life, certain

situations may arise which will necessitate the disposal of

a live (undeployed) air bag assembly. This information

covers proper procedures for disposing of a live air bag

assembly.

Before a live air bag assembly can be disposed of, it must

be deployed. Alive air bag assembly must not be

disposed of through normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDPLOYED AIR

BAG ASSEMBLY MUST NOT BE DISPOSED OF

THROUGH NORMAL REFUSE CHANNELS. THE

UNDEPLOYED AIR BAG ASSEMBLY CONTAINS

SUBSTANCES THAT CAN CAUSE SEVERE ILLNESS

OR PERSONAL INJURY IF THE SEALED CONTAINER

IS DAMAGED DURING DISPOSAL. DISPOSAL IN

ANY MANNER INCONSISTENT WITH PROPER

PROCEDURES MAY BE A VIOLATION OF FEDERAL,

STATE, AND / OR LOCAL LAW.

In situations which require deployment of a live air bag

assembly module, deployment may be accomplished

inside or outside the vehicle. The method employed

depends upon the final disposition of the particular

vehicle, as noted in “Deployment Outside Vehicle” and

“Deployment Inside Vehicle” in this section.

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

air bag assembly is replaced. Deployment and disposal

of a malfunctioning air bag assembly is, of course, subject

to any required retention period.

For deployment of a live (undeployed) air bag assembly

outside the vehicle, the deployment procedure must be

followed exactly. Always wear safety glasses during this

deployment procedure until a deployed air bag assembly

is scrapped or until an undeployed air bag assembly is

shipped. Before performing the procedures you should

be familiar with servicing the SRS and with proper

handling of the air bag assembly. Procedures should be

read fully before they are performed.

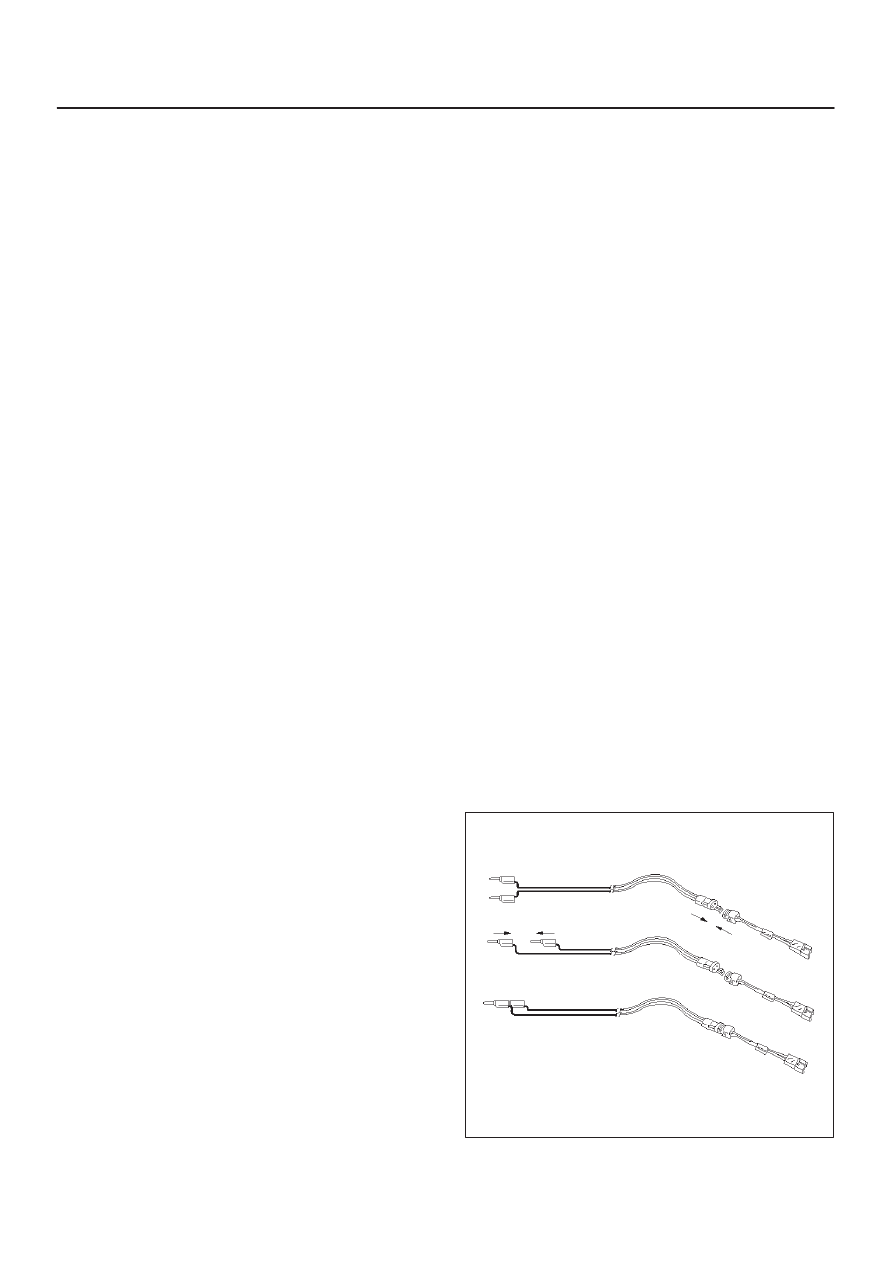

The following procedure requires use of J–41434 SRS

deployment harness with appropriate pigtail adapter. Do

not attempt procedure without J–41434 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

DRIVER AIR BAG ASSEMBLY. DEPLOYMENT

HARNESS SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE AIR

BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED TO

IT. WEAR SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

NOTE: This information applies only to driver air bag

assembly . Refer to “Deployment Outside Vehicle

(Passenger Air Bag Assembly)” in this section for

information on passenger air bag assembly scrapping.

1. Turn ignition switch to “LOCK”, remove key and put

on safety glasses.

2. Inspect J–41434 SRS Deployment Harness and

appropriate pigtail adapter for damage. If harness or

pigtail adapter is damaged, discard and obtain a

replacement.

3. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the air

bag is to be deployed.

827RS004