Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 427

7A1–18 TRANSMISSION CONTROL SYSTEM (4L30–E)

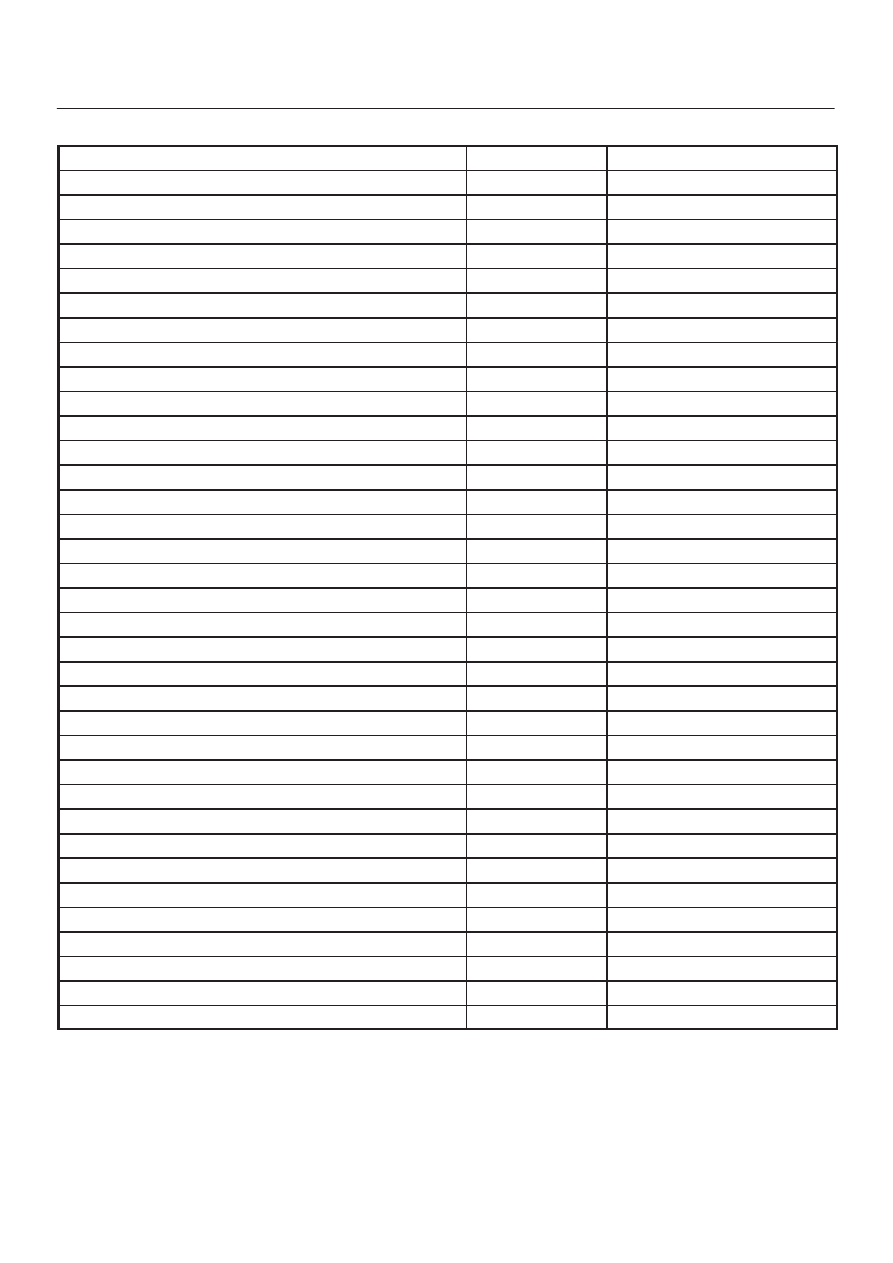

Transmission Data

Tech 2 string

Unit

Engine running at idle

Ignition Voltage

V

12.8

∼

14.1 V

Engine Speed

RPM

750

∼

900 RPM

Vehicle Speed

km/h, MPH

0 MPH

AT Output Speed (Automatic Transmission)

RPM

0 RPM

AT Input Speed Ratio (Automatic Transmission)

0.0

Throttle Position

%

0 %

AT Oil Temperature (Automatic Transmission)

°

C,

°

F

70

∼

80

°

C (158

∼

176

°

F)

Transmission Temperature

°

C,

°

F

75

∼

110

°

C (167

∼

230

°

F)

AT Oil Temperature Lamp (Automatic Transmission)

On/Off

Off

AT Oil Life Monitor (Automatic Transmission)

%

100 %

AT Oil Life Lamp (Automatic Transmission)

On/Off

(Not used)

Commanded Gear

1

Current Gear

1

Mode Switch A

Inactive/Active

Active

Mode Switch B

Inactive/Active

Inactive

Mode Switch C

Inactive/Active

Inactive

Mode Switch G

Inactive/Active

Active

Selector Position

Park

1–2 Shift Solenoid A

On/Off

Off

2–3 Shift Solenoid B

On/Off

On

Solenoid Brake Band

On/Off

Off

TCC Slip Speed

RPM

750

∼

900 RPM

TCC Solenoid

On/Off

Off

TCC Duty Cycle

%

0 %

PCS Current (Pressure Control Solenoid)

A

approx. 1.0 A

PCS Duty Cycle (Pressure Control Solenoid)

%

approx. 45

∼

60 %

Desired PCS Pressure (Pressure Control Solenoid)

kPa

43

∼

52 kPa

Shift Pressure

kPa

43

∼

52 kPa

Brake Switch

On/Off

On

Winter Switch

On/Off

Off

Winter Drive Lamp

On/Off

Off

Power Switch

Normal

Normal

Power Drive Lamp

Off/On

Off

Emergency Mode

Inactive/Active

Inactive

ABS Status

On/Off

(Not used)