Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 389

6E–586

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Electrical Components

The electrical components that make up the enhanced

EVAP system are:

D

Fuel Tank (Vapor) Pressure Sensor. The fuel tank

pressure sensor is a three-wire strain gauge sensor

similar to a common MAP sensor. However, the fuel

tank pressure sensor has very different electrical

characteristics due to its pressure differential design.

The sensor measures the difference between the air

pressure (or vacuum) in the fuel tank and the outside

air pressure.

The sensor mounts at the top of the fuel pump

assembly. A three-wire electrical harness connects it to

the PCM. The PCM supplies a five-volt reference

voltage and a ground to the sensor. The sensor will

return a voltage between 0.1 and 4.9 volts. When the

air pressure in the fuel tank is equal to the outside air

pressure, such as when the fuel cap is removed, the

output voltage of the sensor will be 1.3 to 1.7 volts.

When the air pressure in the fuel tank is 4.5 in. H2O

(1.25 kPa), the sensor output voltage will be 0.5

±

0.2 V.

When there is neither vacuum nor pressure in the fuel

tank, the sensor voltage will be 1.5 V. At –14 in. H2O

(–3.75 kPa), the sensor voltage will be 4.5

±

0.2 V.

D

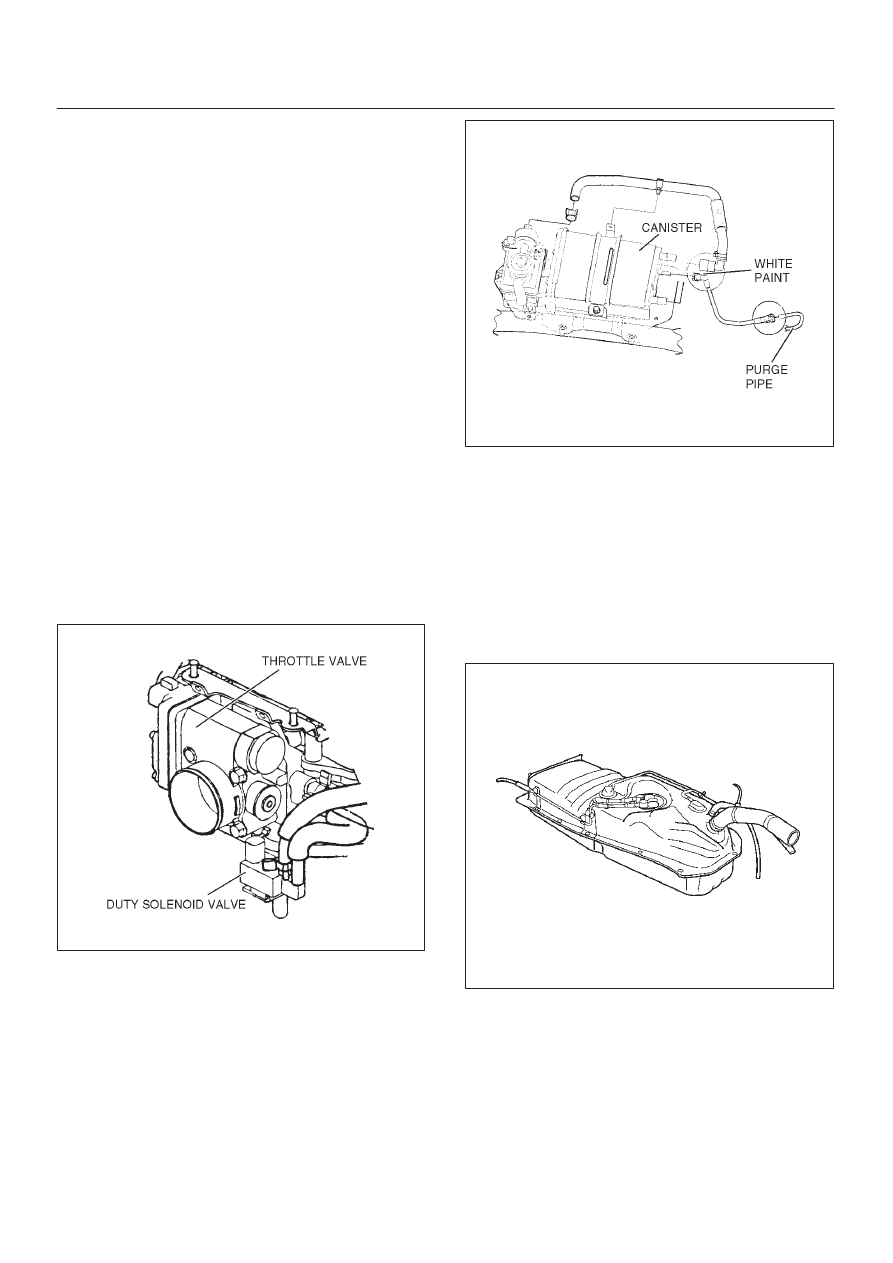

EVAP Canister Purge Solenoid. Normally closed, the

purge solenoid opens upon the PCM’s signal to allow

engine vacuum to purge gasoline fumes from the

canister. Mounted on the water pipe to front of the

engine assembly.

060R200080

D

EVAP Canister Vent Solenoid. Located next to the

canister, the vent solenoid opens to allow air into the

EVAP system. Fresh air is necessary to completely

remove gasoline fumes from the canister during

purge. The EVAP vent solenoid closes to seal off the

evaporative emissions system for leak testing.

060R200081

D

Fuel Level Sensor. The fuel level sensor is an

important input to the PCM for the enhanced EVAP

system diagnostic. The PCM needs fuel level

information to know the volume of fuel in the tank.

The fuel level affects the rate of change of air

pressure in the EVAP system. Several of the

enhanced EVAP system diagnostic sub-tests are

dependent upon correct fuel level information. The

diagnostic will not run when the tank is less than 15%

or more than 85% full. Be sure to diagnose any Fuel

Level Sensor DTCs first, as they can cause other

DTCs to set.

014RW114

D

Manifold Absolute Pressure (MAP) Sensor. The

PCM compares the signals from the fuel tank

pressure sensor and the MAP sensor to ensure that a

relative vacuum is maintained the EVAP system.