Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 384

6E–566

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Positive Crankcase Ventilation

(PCV) Valve

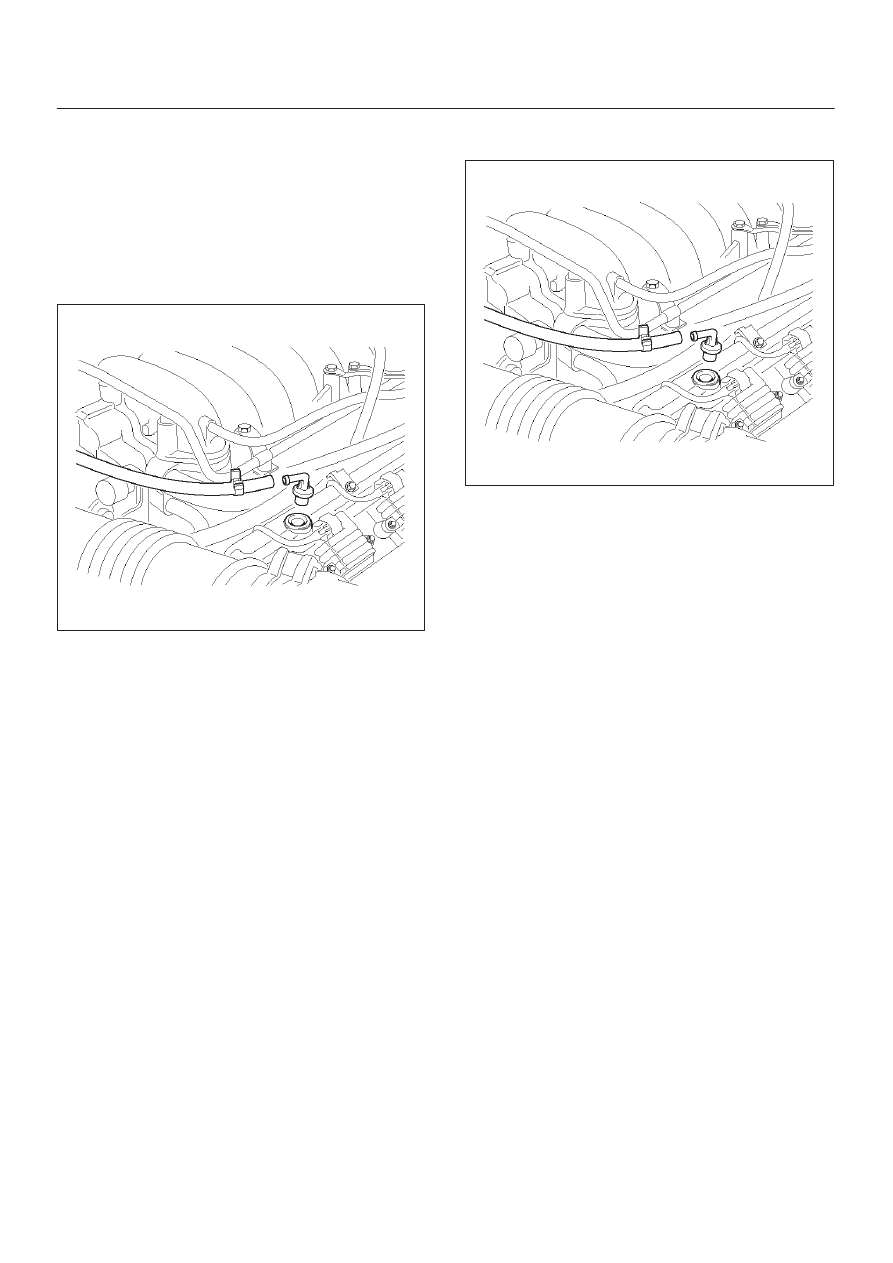

Removal Procedure

1. Remove the vacuum hose at the PCV valve.

D

Slide the clamp back to release the hose.

2. Pull the PCV valve from the rubber grommet in the

right valve cover.

014RW097

Inspection Procedure

Before inspecting the PCV valve, make sure that the

hoses are connected properly and are in good condition.

Also check that the oil pan and rocker cover gaskets are

sealing properly.

PCV Valve

1. Run the engine at normal operating temperature.

2. Disconnect the valve from the rocker cover.

RESULT: A hissing noise should be heard from the

valve. If no noise is heard, the PCV valve or hose is

plugged.

3. Remove the PCV valve from the engine.

a. Blow air into the rocker cover side of the valve.

RESULT: Air should pass freely.

b. Blow air into the air cleaner side of the valve.

RESULT: Air should not pass through the valve.

4. Re-install the PCV valve and remove the oil filler cap.

RESULT: A small vacuum should be felt at the oil filler

hole.

Installation Procedure

1. Push the PCV valve into the rubber grommet in the

left valve cover.

2. Install the vacuum hose on the PCV valve and secure

the vacuum hose with the clamp.

014RW097

Wiring and Connectors

Wiring Harness Service

The control module harness electrically connects the

control module to the various solenoids, switches and

sensors in the vehicle engine compartment and

passenger compartment.

Replace wire harnesses with the proper part number

replacement.

Because of the low amperage and voltage levels utilized

in powertrain control systems, it is essential that all wiring

in environmentally exposed areas be repaired with crimp

and seal splice sleeves.

The following wire harness repair information is intended

as a general guideline only. Refer to

Chassis Electrical

section for all wire harness repair procedures.

Connectors and Terminals

Use care when probing a connector and when replacing

terminals. It is possible to short between opposite

terminals. Damage to components could result. Always

use jumper wires between connectors for circuit

checking. NEVER probe through Weather-Pack seals.

Use an appropriate connector test adapter kit which

contains an assortment of flexible connectors used to

probe terminals during diagnosis. Use an appropriate

fuse remover and test tool for removing a fuse and to

adapt the fuse holder to a meter for diagnosis.

Open circuits are often difficult to locate by sight because

oxidation or terminal misalignment are hidden by the

connectors. Merely wiggling a connector on a sensor, or

in the wiring harness, may temporarily correct the open

circuit. Intermittent problems may also be caused by

oxidized or loose connections.

Be certain of the type of connector/terminal before

making any connector or terminal repair. Weather-Pack

and Com-Pack III terminals look similar, but are serviced

differently.