Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 356

6E–454

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

DTC P1295 - ETC Power Management Mode

(Cont'd)

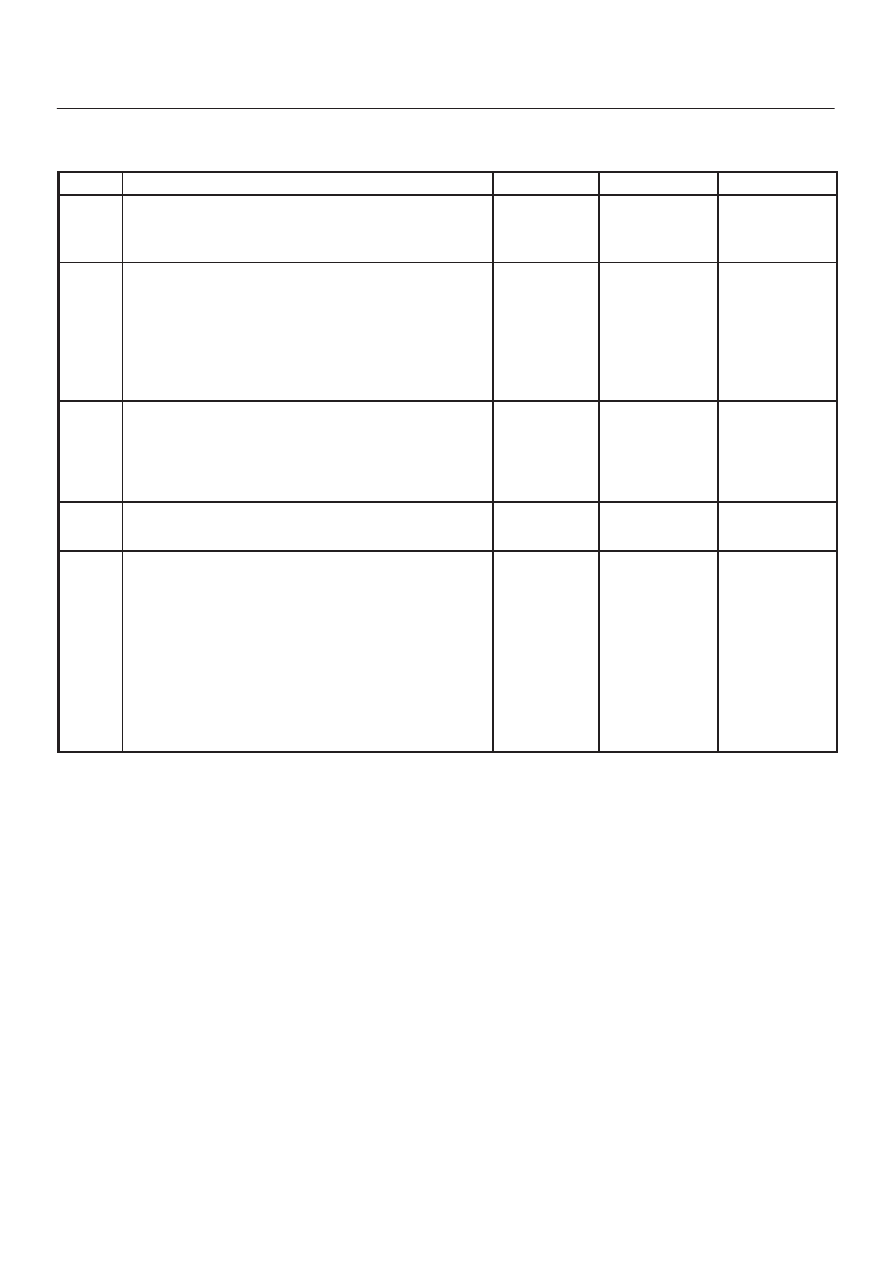

Step

No

Yes

Value(s)

Action

19

1. Ignition “ON”, engine not running.

2. Observe the MAP reading on the Tech 2.

Is the MAP reading less than the specified value?

65kPa

Go to

Step 20

Go to

Step 23

20

1. Disconnect the MAP sensor.

2. Connect a test 5 volt reference circuit and the MAP

signal at the MAP sensor harness connector.

3. Observe the MAP reading on the Tech 2.

Is the MAP reading less than the specified value? (If no,

start with diagnosis chart for other sensors in the circuit

and see if 5V returns.)

5V

Go to

Step 22

Go to

Step 21

21

1. Check the MAP signal circuit between the PCM and

MAP ground circuit.

2. If the MAP signal circuit is open or shorted, repair it

as necessary.

Was the MAP signal circuit open or shorted?

—

Verify repair

Go to

Step 23

22

Replace the MAP sensor.

Is the action complete?

—

Verify repair

—

23

Replace the PCM.

IMPORTANT:

The replacement PCM must be programmed. Refer to

ON-Vehicle Service in Power Control Module and

Sensors for procedures.

And also refer to latest Service Bulletin. Check to see if

the latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Verify repair

—