Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 350

6E–430

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis Trouble Code(DTC)

P1221 TPS1 – TPS2 Correlation(Circuit Performance)

060R200069

Circuit Description

D

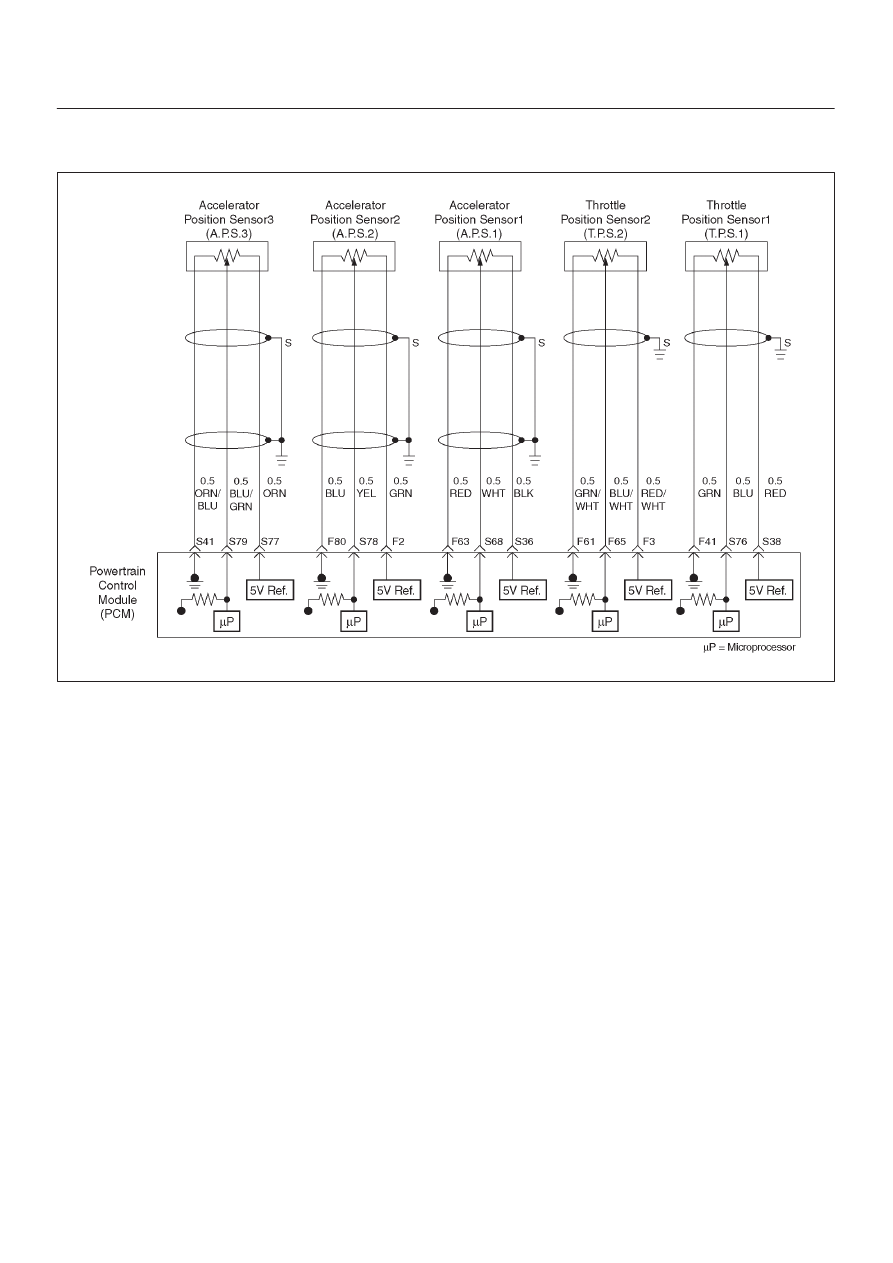

The powertrain control module (PCM) controls engine

speed by adjusting the position of the throttle control

valve (DC motor). The throttle motor is a DC motor

driven by one coil. The PCM applies current to DC

motor coil in duty (%) to adjustment the valve into a

passage in the throttle body to air flow.

This method allows highly accurate control of engine

speed and quick response to changes in engine

load.

D

The accelerator position (AP) sensor circuit provides a

voltage signal relative to accelerator pedal angle.

The accelerator pedal angle (AP1) will vary from

about 13% at idle position to about 87% at open

throttle(WOT).

APS signal is used to determine which DC will adjust

throttle position.

After the APS signal has been processed by the

PCM, it will command the DC motor to move the

throttle position.

D

Accelerator pedal – Check for objects blocking the AP

sensor or pedal arm with spring, and excessive

deposits in the accelerator pedal arm and on the

accelerator pedal.

Conditions for Setting the DTC

D

The ignition is “ON”.

D

A difference of between TPS1 and TPS2 correlation of

over 6.5% within 125 milliseconds.

Action Taken When the DTC Sets

D

The PCM will not turn the malfunction indicator lamp

(MIL) “ON”.

D

The PCM will store conditions which were present

when the DTC was set as Failure Records only. This

information will not be stored as Freeze Frame data.

Condition for Clearing the MIL/DTC

D

A history DTC 1221 will clear after 40 consecutive trip

cycles during which the warm up cycles have occurred

without a fault.

D

DTC 1221 can be cleared using the Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Visually/physically inspect for the following throttle

valve conditions.

3.Visually/physically inspect for the following

accelerator pedal conditions.

5.Check the following circuits for throttle valve and DC

moter. Check the following TP sensor resistance

and DC motor.