Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 289

6E–186

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

D

Evaporative emissions (EVAP) canister purge – Check

for fuel saturation. If full of fuel, check the canister

control and hoses. Refer to

Evaporative Emission

(EVAP) Control System.

D

MAF sensor –The system can go rich if the MAF

sensor signal indicates an engine airflow

measurement that is not correct. Disconnect the MAF

sensor to see if the rich condition is corrected. If so,

replace the MAF sensor.

D

Check for a leak in fuel pressure regulator diaphragm

by checking the vacuum line to the regulator for the

presence of fuel. There should be no fuel in the

vacuum line.

D

TP sensor – An intermittent TP sensor output will

cause the system to go rich, due to a false indication

of the engine accelerating.

D

Shorted Heated Oxygen Sensor (HO2S) – If the HO2S

is internally shorted the HO2S voltage displayed on the

Tech 2 will be over 1 volt. Try disconnecting the

affected HO2S with the key “ON”, engine “OFF”. If the

displayed HO2S voltage changes from over 1000 mV

to around 450 mV, replace the HO2S. Silicon

contamination of the HO2S can also cause a high

HO2S voltage to be indicated. This condition is

indicated by a powdery deposit on the portion of the

HO2S exposed to the exhaust stream. If

contamination is noticed, replace the affected HO2S.

D

Open HO2S Signal Circuit of Faulty HO2S – A poor

connection or open in the HO2S signal circuit can

cause the DTC to set during deceleration fuel mode.

An HO2S which is faulty and not allowing a full voltage

swing between the rich and lean thresholds can also

cause this condition. Operate the vehicle while

monitoring the HO2S voltage with a Tech 2. If the

HO2S voltage is limited within a range between

300 mV to 600 mV, check the HO2S signal and wiring

and associated terminal connections.

D

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. DTC P0138 being set during deceleration fuel mode

operation may indicate a condition described in the

“Diagnostic Aids” above. If the DTC P0138 test

passes while the Failure Records conditions are

being duplicated, an intermittent condition is

indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

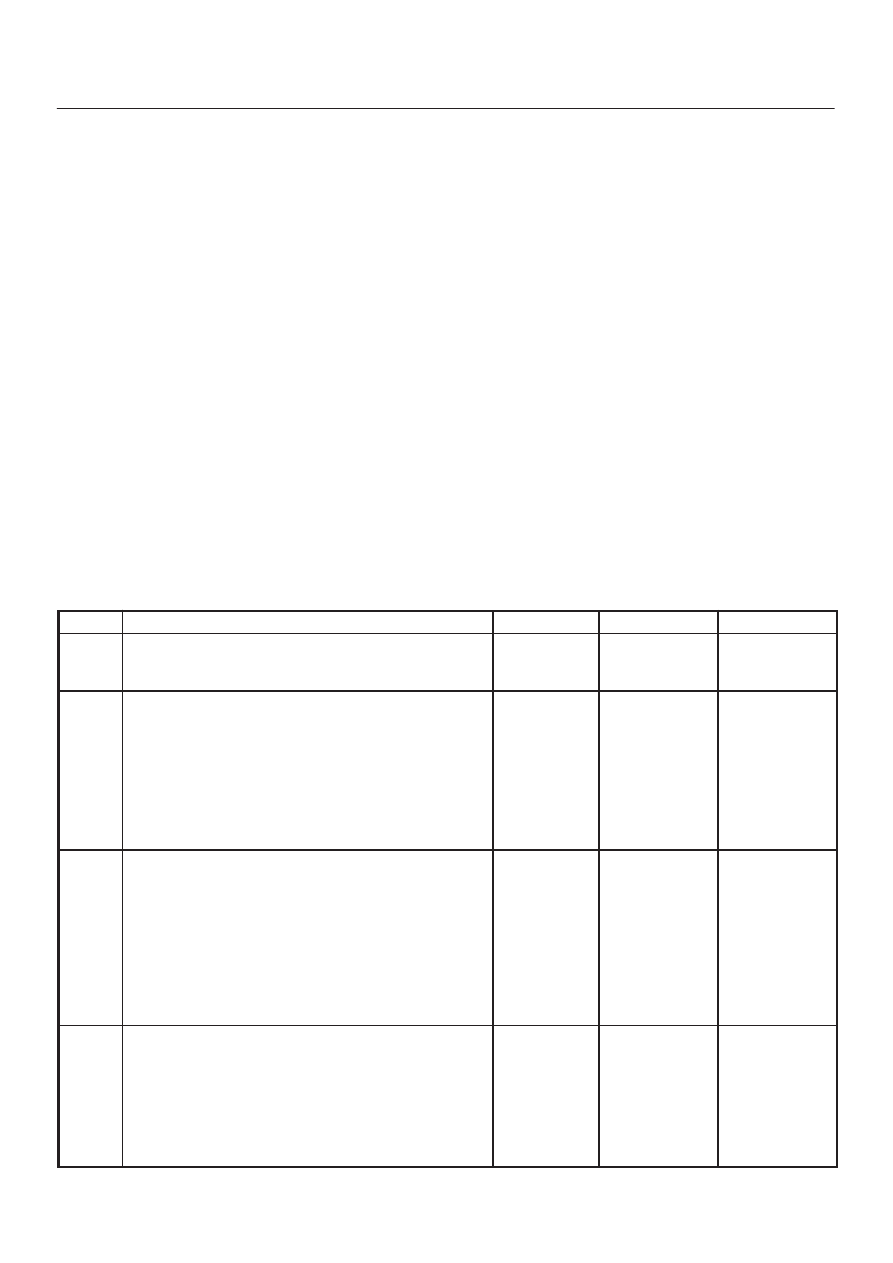

DTC P0138 – HO2S Circuit High Voltage Bank 1 Sensor 2

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Install the Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using a Tech 2, monitor Bank 1 HO2S 2 voltage.

Does the Bank 1 HO2S voltage remain above the

specified value?

952 mV

(500 mV in

deceleration

fuel cutoff

mode)

Go to

Step 4

Go to

Step 3

3

1. Ignition “ON”, review and record Tech 2 Failure

Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC” info for DTC P0138

until the DTC P0138 test runs.

4. Note the test result.

Does the Tech 2 indicate DTC P0138 failed this

ignition?

—

Go to

Step 4

Refer to

Diagnostic

Aids

4

1. Ignition “OFF”.

2. Disconnect Bank 1 HO2S 1.

3. Ignition “ON”.

4. At the HO2S Bank 1 Sensor 2 connector (PCM

side), use a DVM to measure voltages at the high

and low signal terminals.

Are the voltages above the specified range?

3-4 V

Go to

Step 5

Go to

Step 6