Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 242

6D3–23

STARTING AND CHARGING SYSTEM (6VE1 3.5L)

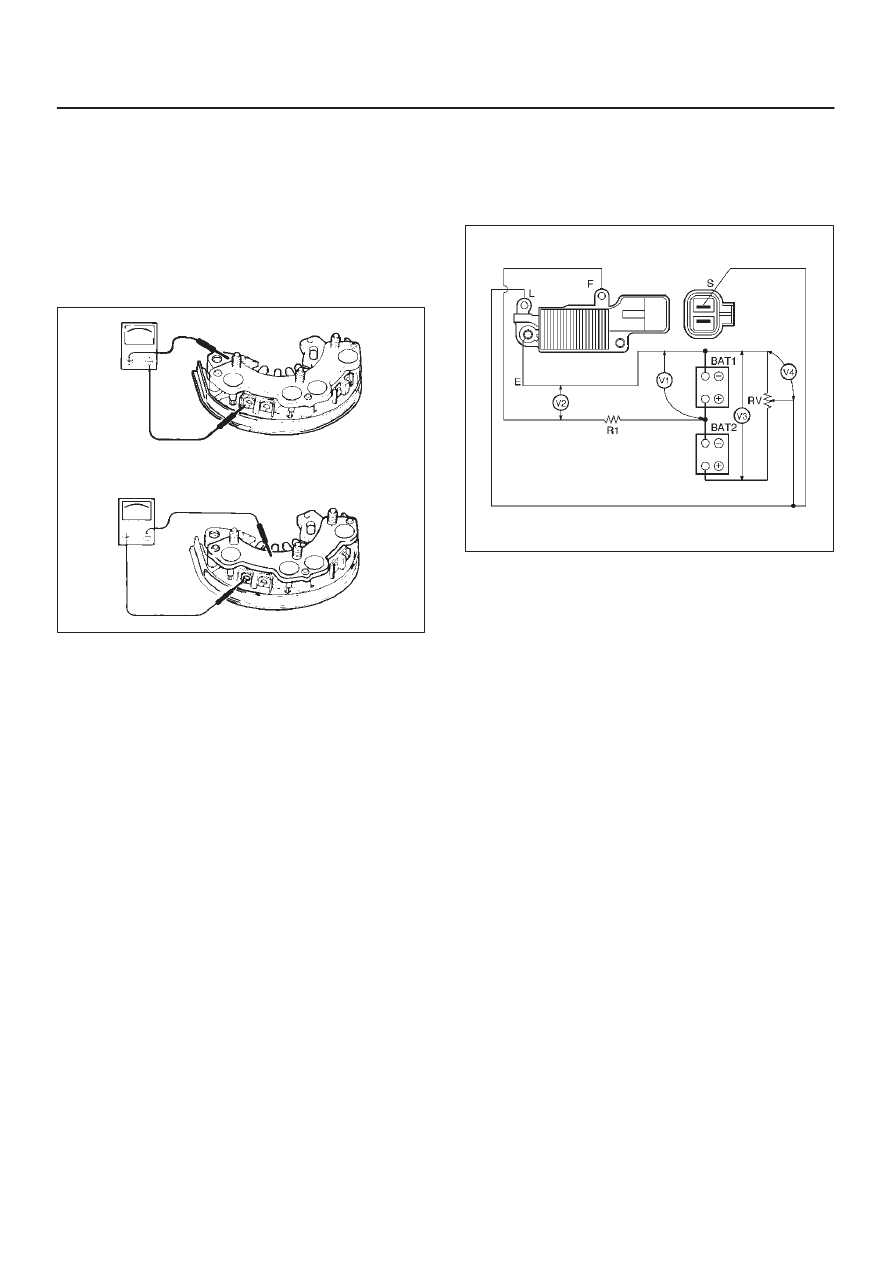

Rectifier Assembly

1. Measure the resistance between each diode terminal

and aluminum diode fin in forward and reverse

directions with the connection of the tester leads

switched. The diodes are normal if resistance is

nearly zero ohms in one direction and is infinitely high

in the other direction.

2. If a diode has no resistance or equal resistance in

both directions, it is defective and should be replaced

together with the holder.

066RS036

IC Regulator Assembly

Connect a variable resistor, two 12V batteries, a fixed

resistor, and a voltmeter to the IC regulator as shown in

illustration.

a. Measuring equipment specifications

1. Fixed resistor (R1) : 10 Ohms /3W

2. Variable resistor (Rv) : 0-300 Ohms/12W

3. Batteries (BAT1, BAT2) : 12V (2 Batteries)

4. DC voltmeter : 0-50V/0.5 steps (4 Check points)

b. Measuring procedure

1. Measure the voltage “V1” across the first battery

(BAT1). If the reading is between 10 and 13 volts,

the battery is normal.

2. Measure the voltage “V3” across both the batteries

(BAT1, BAT2). If the reading is between 20 and 26

bolts, the batteries are normal.

3. Gradually increase the resistance of the variable

resistor from zero. Measure the voltage “V2” (the

voltage across the F and E terminals).

Check to see that the voltage across “V1” changes at

this time. If there is no change, the voltage regulator

is faulty and must be replaced.

4. Measure the voltage at “V4” (the voltage across the

variable resistor center tap and terminal E with the

variable resistor resistance held constant). The

measured voltage should be within the specified

(14.4

±

0.3 volts) limits. If it is not, the regulator must

be replaced.

066RX003

Reassembly

To reassemble, follow the disassembly steps in the

reverse order, noting the following points:

NOTE:

D

Never make battery connections with polarities

reversed, or battery will be shorted via the diodes.

This will cause damage to the diodes.

D

Do not connect generator B terminal to ground; it is

connected directly to the battery.

This cable will burn if it is connected to ground.

D

Make sure to disconnect the positive (+) terminal of

the battery when quick-charging battery .

Diodes may be damaged due to abnormal pulse

voltage generated by the quick charger.

D

When reassembling the front section to rear section,

insert a stiff wire into hole in the rear face of the rear

cover from the outboard side to support the brush in

raised position, then insert the front section to which

rotor is assembled.

D

Reassemble parts carefully to be sure they fit into

their original position, paying attention to the

insulated portions.

D

Wipe insulating tubes, washers and plates clean and

install them in position carefully to avoid getting oil or

grease on them.