Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 206

6A–11

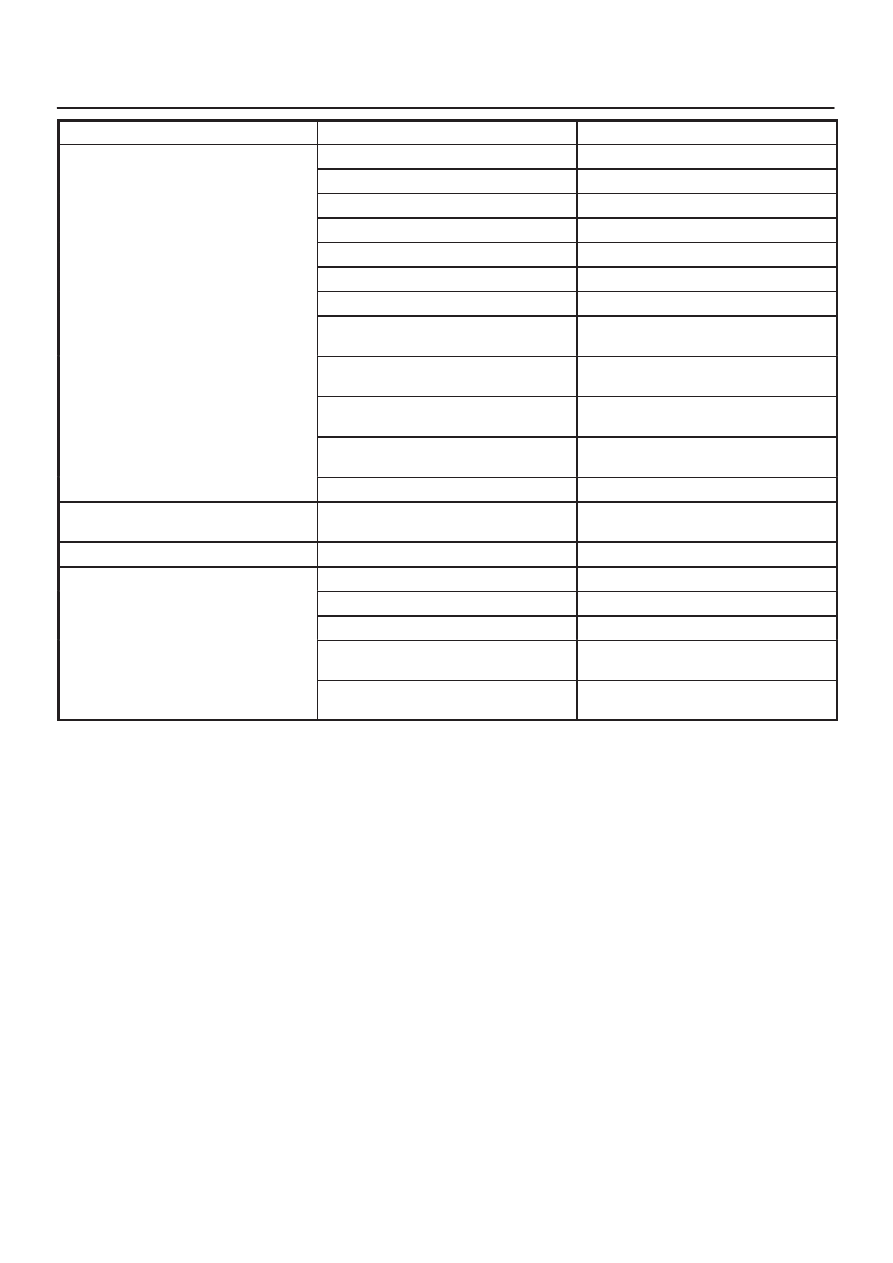

ENGINE MECHANICAL (6VE1 3.5L)

Condition

Correction

Possible cause

Engine overheating

Level of Engine Coolant too low

Replenish

Fan clutch defective

Replace

Incorrect fan installed

Replace

Thermostat defective

Replace

Engine Coolant pump defective

Correct or replace

Radiator clogged

Clean or replace

Radiator filler cap defective

Replace

Level of oil in engine crankcase too

low or wrong engine oil

Change or replenish

Resistance in exhaust system

increased

Clean exhaust system or replace

defective parts

Throttle Position Sensor adjustment

incorrect

Replace with Throttle Valve ASM

Throttle Position Sensor circuit open

or shorted

Correct or replace

Cylinder head gasket damaged

Replace

Engine overcooling

Thermostat defective

Replace (Use a thermostat set to

open at 82

°

C (180

°

F))

Engine lacks compression

————

Refer to Hard Start

Others

Tire inflation pressure abnormal

Adjust to recommended pressures

Brake drag

Adjust

Clutch slipping

Adjust or replace

Level of oil in engine crankcase too

high

Correct level of engine oil

Exhaust Gas Recirculation Valve

defective

Replace