Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 185

5C–57

POWER–ASSISTED BRAKE SYSTEM

Machining The Drum

If a drum is to be machined, only enough metal should be

removed to obtain a true, smooth braking surface. If a

drum does not clean-up when machined to a maximum

diameter, it must be replaced. Removal of more metal will

affect dissipation of heat and may cause distortion of the

drum.

After refinishing, replace any drum that exceeds a

maximum inside diameter of 296.5 mm (11.673 in). Do

not use a brake drum that is not within the specification.

Maximum inside diameter: 296.5 mm (11.673 in)

Wheel Cylinder Assembly (4

×

2 Model)

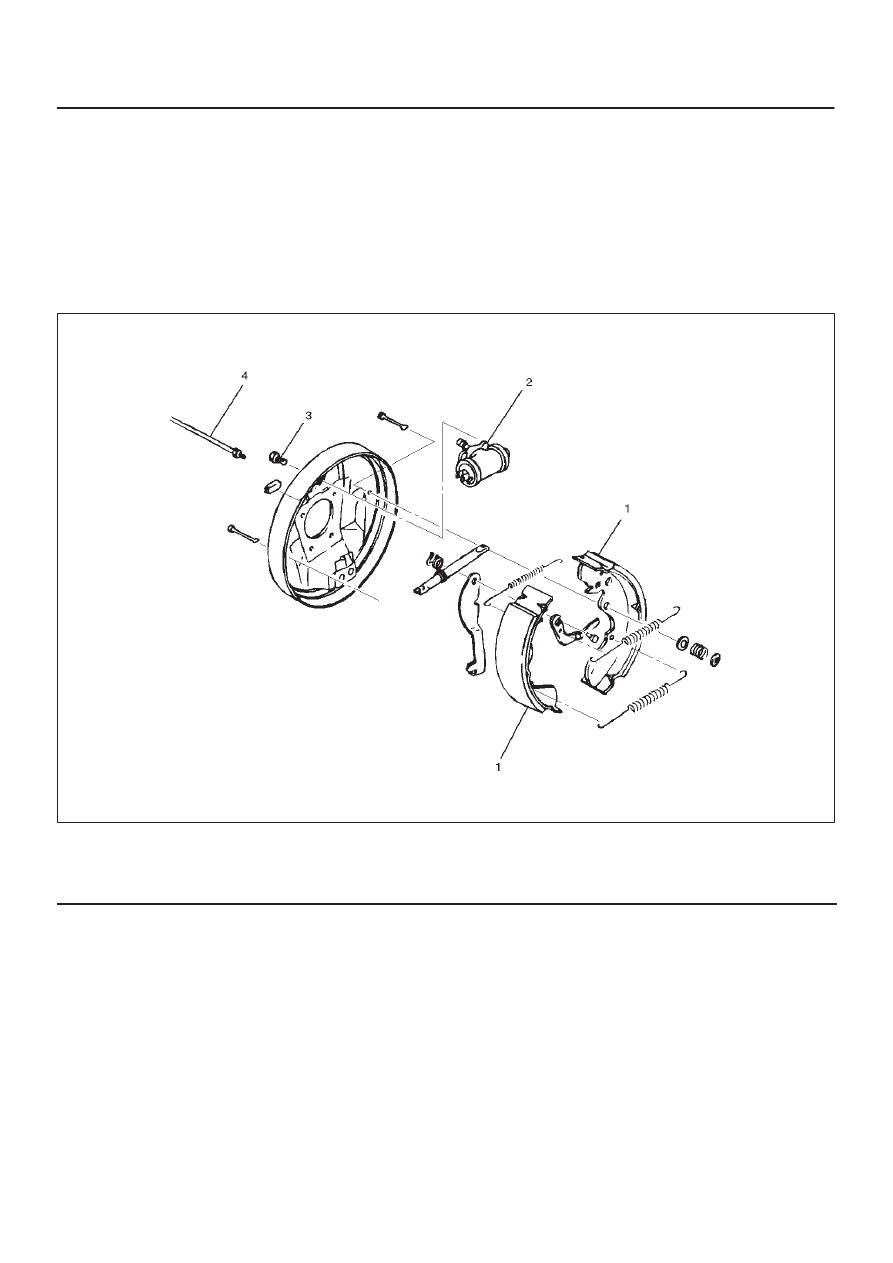

Wheel Cylinder Assembly and Associated Parts

305RW003

Legend

(1) Brake Linings

(2) Wheel Cylinder

(3) Bolts

(4) Brake Pipe

Removal

1. Remove brake linings (1).

D

Refer to

Brake Lining and Associated Parts in this

section.

2. Remove brake pipe (4).

D

Plug the opening in the line to prevent fluid loss and

contamination.

3. Remove bolts (3) and wheel cylinder (2).

Installation

1. Install wheel cylinder (2) and tighten bolts (3) to the

specified torque.

Torque: 10 N·m (8 lb ft)

2. Install brake pipe (4) and tighten the nut to the

specified torque.

Torque: 16 N·m (12 lb ft)

3. Install brake linings (1).

D

Refer to

Brake Lining Replacement in this section.

D

Bleed brake system. Refer to

Hydraulic Brake in

this section.