Content .. 1686 1687 1688 1689 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1688

SUPPLEMENTAL RESTRAINT SYSTEM

9J–9

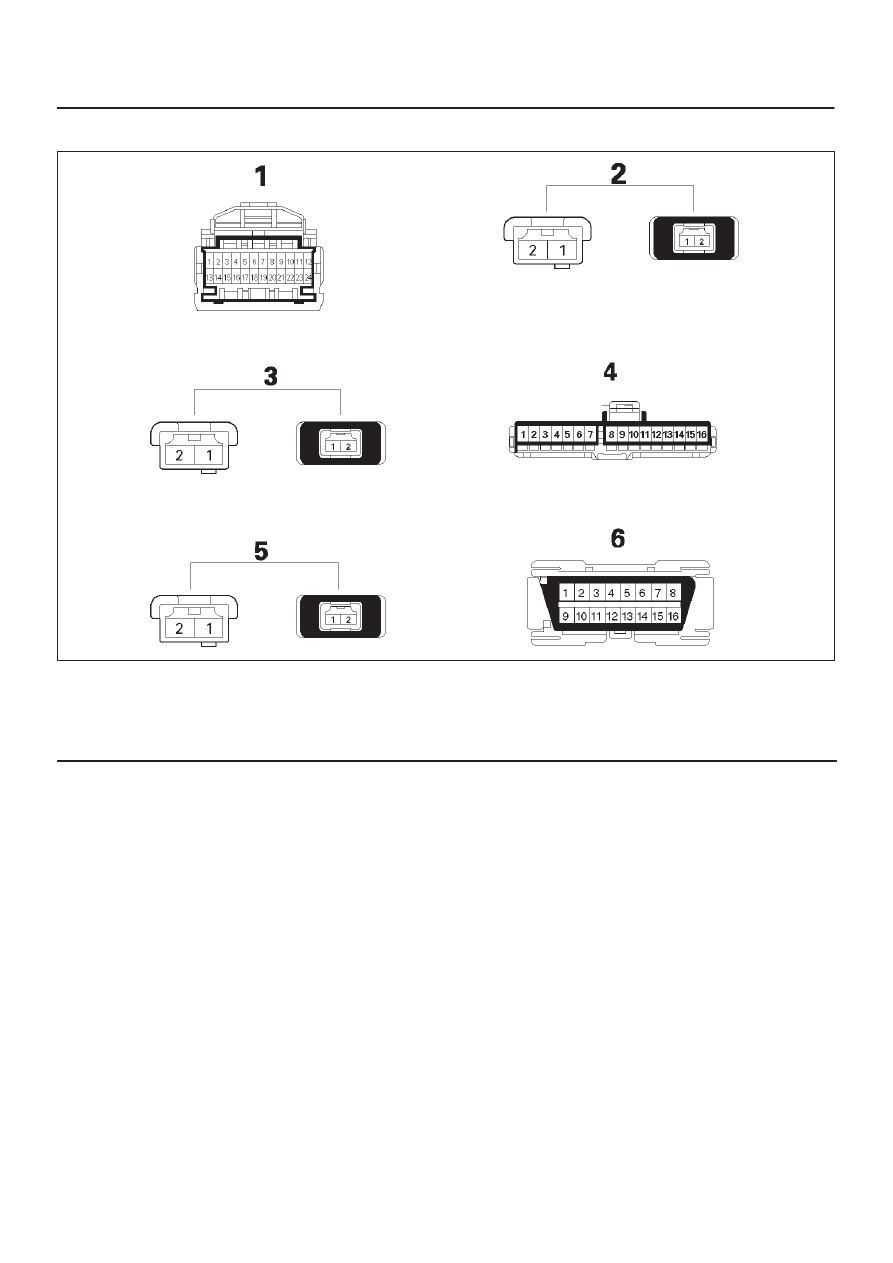

SRS Connector Body Face Views

D09RW003

Legend

(1) Sensing and Diagnostic Module (SDM)

(2) Driver Air Bag Assembly

(3) Passenger Air Bag Assembly

(4) “Air Bag” Warning Lamp

(5) Supplemental Restraint System (SRS) Coil

Assembly

(6) Data Link Connector (DLC)

Repairs and Inspections Required

After an Accident

NOTE: If any SRS components are damaged, they must

be replaced. If SRS component mounting points are

damaged, they must be replaced.

D

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from an

authorized dealer; they may be used for SRS repairs.

D

Do not attempt to service the SDM, the SRS coil

assembly, or the air bag assembly. Service of these

items is by replacement only.

D

Verify the part number of replacement air bag

assembly.

CAUTION: Never use the air bag assembly from

another vehicle.

Use only the air bag assembly for UE models.

CAUTION: Proper operation of the sensors and

Supplemental Restraint System (SRS) requires that

any repairs to the vehicle structure return it to the

original production configuration. Deployment

requires, at a minimum, replacement of the SDM, air

bag assembly and dimensional inspection of the

steering column. Any visible damage to the SDM

mounting bracket (s) requires replacement, and the

steering column must be dimensionally inspected,

whether deployment occurred or not.

Accident With Deployment – Component

Replacement and Inspections

Certain SRS components must be replaced or inspected

for damage after a frontal crash involving air bag

deployment. Those components are:

D

Air bag assembly

D

SDM

CAUTION: Refer to “SDM Replacement Guidelines”

below for important information on Sensing and

Diagnostic Module (SDM) replacement in both

deployment and non deployment crashes.