Content .. 1467 1468 1469 1470 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1469

6E2–327

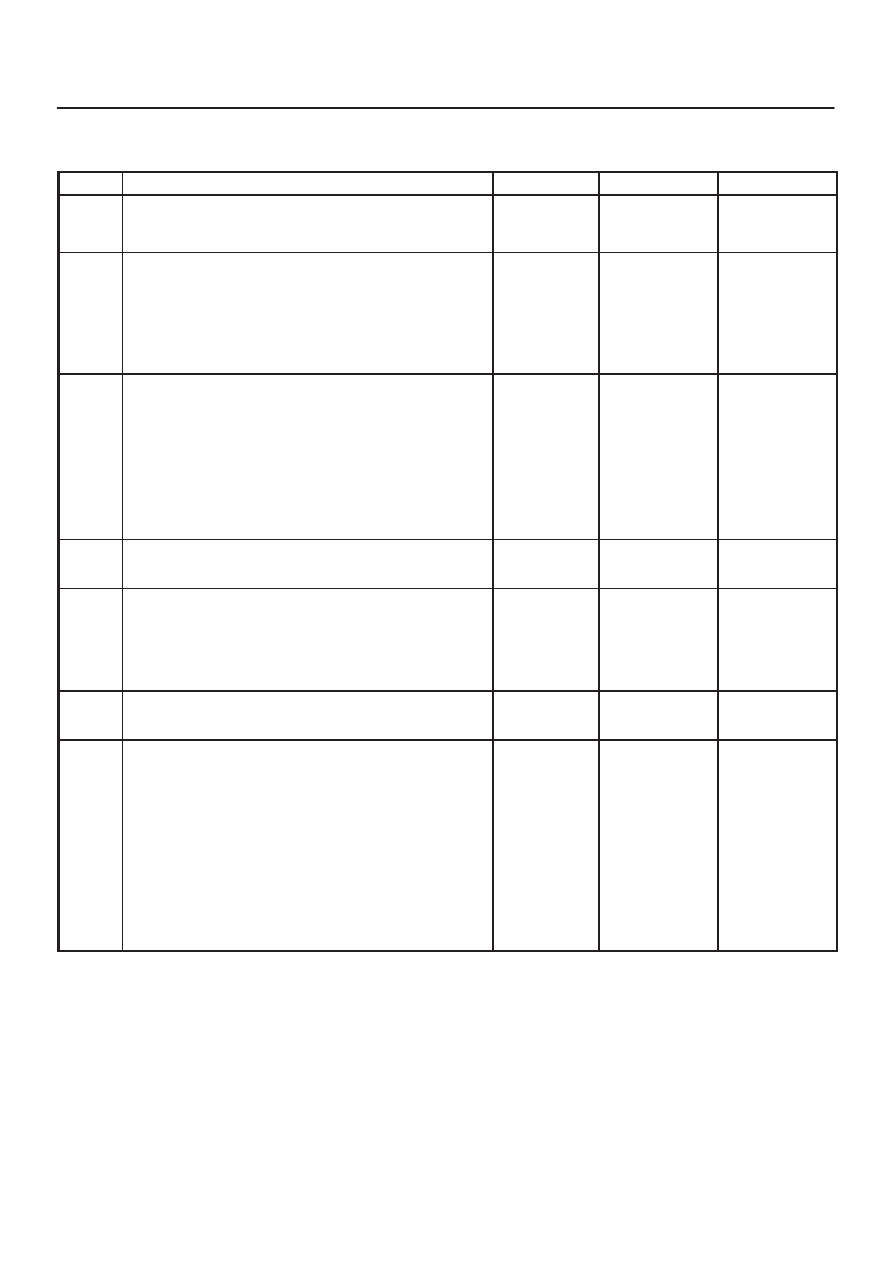

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0445 EVAP Purge Control Circuit Short

Step

Action

Value(s)

Yes

No

1

Was the “On-Board (OBD) System Check” performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Install the Tech 2.

2. Ignition is “ON”,

3. Observe the EVAP purge solenoid reading on the

Tech 2.

Is the EVAP purge solenoid reading near the specified

value?

0%

Refer to

Diagnostic

Aids

Go to

Step 3

3

Check the signal circuit for canister purge solenoid

valve.

1. Ignition is “OFF”.

2. Disconnect the canister purge solenoid valve.

3. Disconnect the PCM.

4. Check the circuit between EVAP purge solenoid

connector and PCM connector.

Is the problem found?

—

Go to

Step 4

Go to

Step 5

4

Repair the circuit as necessary. Is the action complete?

—

Verify repair

—

5

Check the canister purge solenoid valve.

Using a DVM, measure resistance for purge solenoid

valve connector terminal.

Is the purge solenoid valve resistance within the

specified values?

25–30 (at

68

°

F{20

°

C})

Go to

Step 7

Go to

Step 6

6

Replace the canister purge solenoid valve.

Is the action complete?

—

Verify repair

—

7

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed.

Refer to

ON-Vehicle Service in Power Control Module

and Sensors for procedures.

And also refer to latest Service Bulletin.

Check to see if the latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Verify repair

—