Content .. 1453 1454 1455 1456 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1455

6E2–271

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0306 – Cylinder Misfire Detected

(Cont'd)

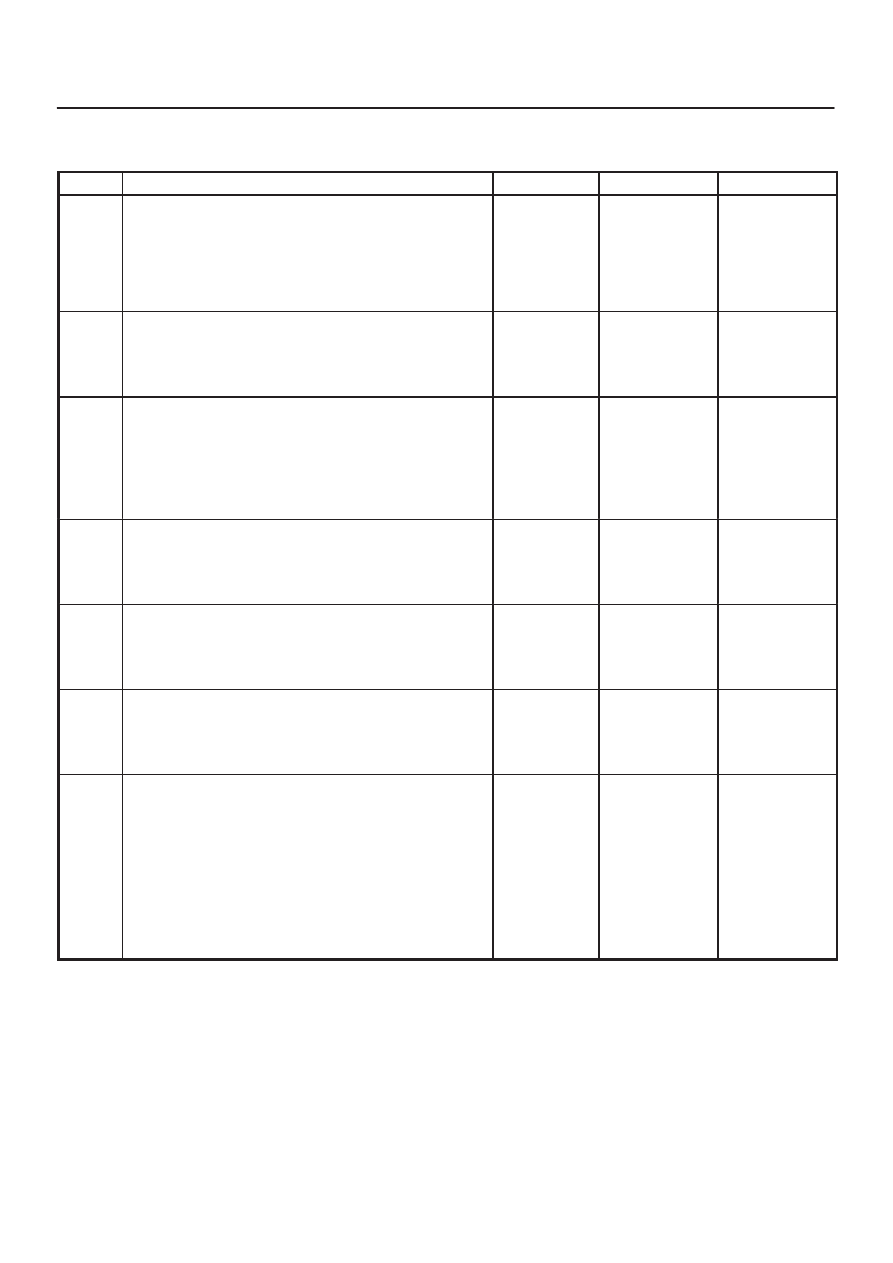

Step

No

Yes

Value(s)

Action

6

1. Remove and visually/physically inspect the ignition

coil associated with cylinder #6. Ensure that the coil

is free of cracks and carbon tracking.

2. If a problem is found, replace the damaged ignition

coil as necessary.

Did the visual inspection reveal a problem?

—

Verify repair

Go to

Step 7

7

1. Measure the ignition coil primary resistance.

2. If resistance is not within the specified value,

replace the faulty ignition coil.

Did the ignition coil require replacement?

2.6-2.7 K

W

Verify repair

Go to

Step 12

8

Remove the cylinder #6 spark plug and visually inspect

the spark plug electrode.

Does the inspection reveal excessive fouling?

—

Go to

Contaminatio

n Diagnosis

chart in

Engine

Mechanical

Diagnosis

Go to

Step 9

9

1. Visually inspect the spark plug insulator for cracks,

carbon tracking, or other damage.

2. If the spark plug is damaged, replace the spark plug.

Did the inspection reveal a problem?

—

Verify repair

Go to

Step 10

10

1. Perform the “Injector Coil/Balance Test”.

2. If any faulty injectors are found, replace them as

necessary.

Did any of the injectors require replacement?

—

Verify repair

Go to

Step 11

11

1. Inspect the intake manifold and the injector O-rings

for a vacuum leak.

2. If a problem is found, repair it as necessary.

Did the inspection reveal a problem?

—

Verify repair

Go to

Step 12

12

Check for an engine mechanical problem. Refer to

Engine Mechanical Diagnosis to diagnose and repair

the following conditions:

D

A faulty or incorrect camshaft

D

Leaking or sticky valves or rings

D

Excessive valve deposits

D

Weak valve springs

D

A leaking head gasket

Was a basic engine mechanical problem found?

—

Verify repair

Refer to

Diagnostic

Aids