Content .. 1416 1417 1418 1419 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1418

6E2–123

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

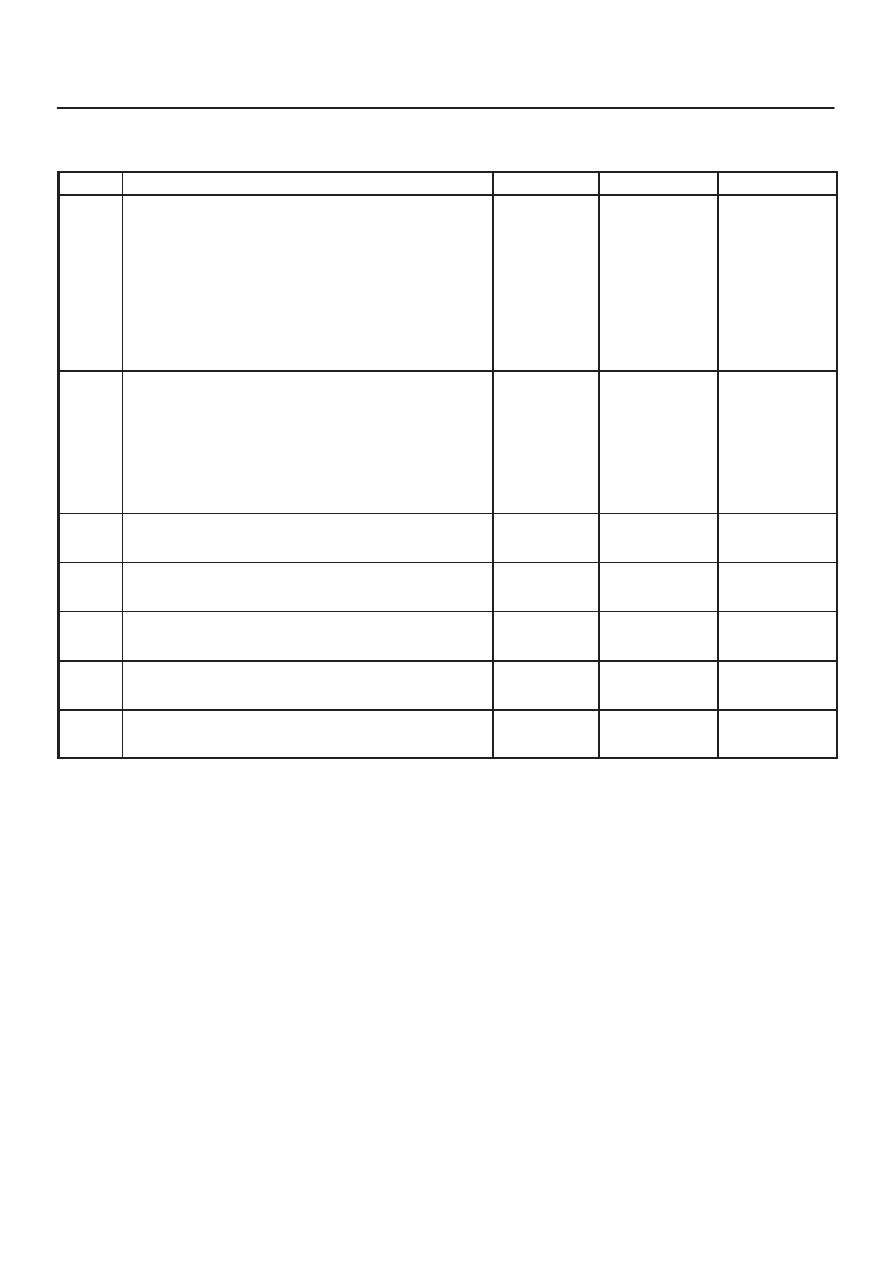

Manifold Absolute Pressure (MAP) Output Check

Step

Action

Value(s)

Yes

No

1

1. Turn the ignition “OFF” and leave it “OFF” for 15

seconds.

2. Ignition “ON”. Don’t crank engine.

3. The Tech 2 should indicate a manifold absolute

pressure (MAP) sensor voltage.

4. Compare this scan reading to scan reading of a

known good vehicle obtained using the exact same

procedure as in Steps 1-4.

Is the voltage reading the same +/–0.40 volt?

—

Go to

Step 2

Go to

Step 5

2

1. Disconnect the vacuum hose at the MAP sensor

and plug the hose.

2. Connect a hand vacuum pump to the MAP sensor.

3. Start the engine.

4. Apply 34 kPa (10 in.Hg) of vacuum and note the

voltage change.

Is the voltage change 1.5-2.1 volts less than Step 1?

—

Go to

Step 3

Go to

Step 4

3

Check the sensor cover for leakage or restriction.

Does the hose supply vacuum to the MAP sensor only?

—

Go to

Step 5

Go to

Step 4

4

Repair the hose blockage.

Is the action complete?

—

Verify repair

—

5

Check the sensor connection.

Is the sensor connection good?

—

Go to

Step 6

Go to

Step 7

6

Refer to

On-Vehicle Service, MAP Sensor.

Is the action complete?

—

Verify repair

—

7

Repair the poor connection.

Is the action complete?

—

Verify repair

—