Content .. 1377 1378 1379 1380 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1379

6D1–4

ENGINE ELECTRICAL (6VD1 3.2L)

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the air conditioning

compressor bracket or the generator mounting

bracket) of the vehicle with the discharged battery.

The ground connection must be at least 450 mm (18

in.) from the battery of the vehicle whose battery is

being charged.

WARNING: NEVER ATTACH THE END OF THE

JUMPER CABLE DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories

have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in reverse order.

Be sure to first disconnect the negative cable from the

vehicle with the discharged battery.

Battery Removal

061RX002

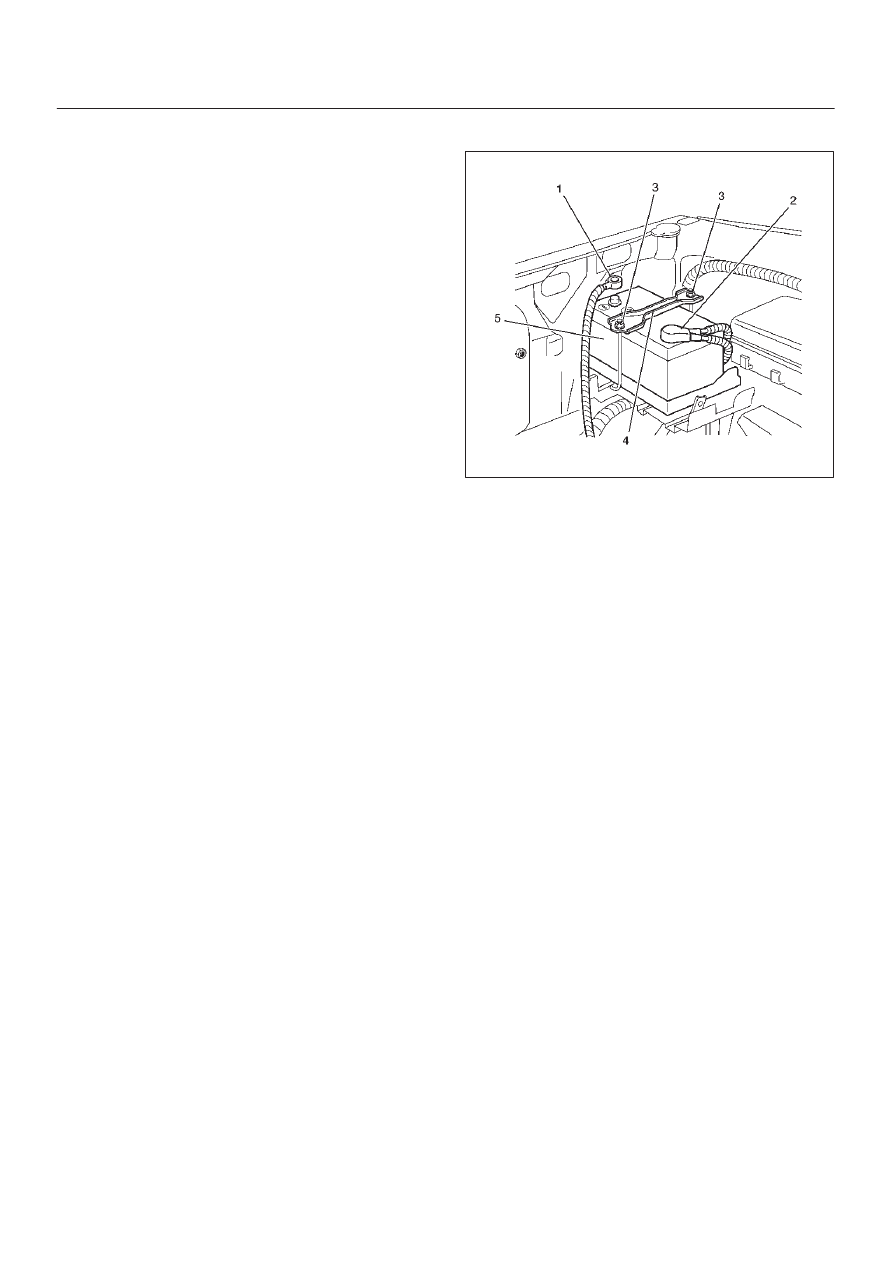

1. Remove negative cable (1).

2. Remove positive cable (2).

3. Remove retainer screw and rods (3).

4. Remove retainer (4).

5. Remove battery (5).

Battery Installation

1. Install battery (5).

2. Install retainer (4).

3. Install retainer screw and rods (3).

NOTE: Make sure that the rod is hooked on the body

side.

4. Install positive cable (2).

5. Install negative cable (1).