Content .. 1341 1342 1343 1344 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1343

6E1–448

RODEO Y22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

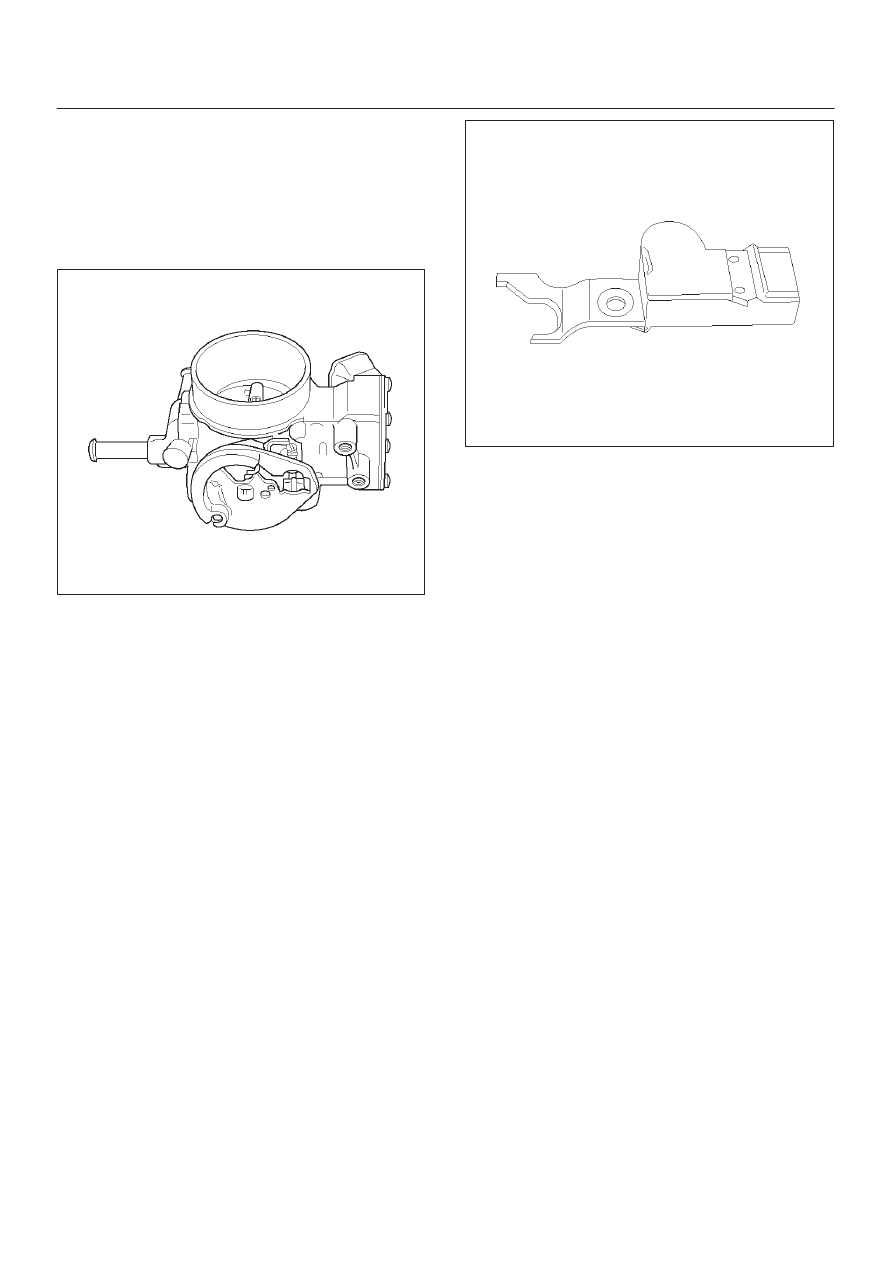

Throttle Body Unit

The throttle body has a throttle plate to control the amount

of air delivered to the engine. The TP sensor and IAC

valve are also mounted on the throttle body.

Vacuum ports located behind the throttle plate provide the

vacuum signals needed by various components. Engine

coolant is directed through a coolant cavity in the throttle

body to warm the throttle valve and to prevent icing.

014RX040

GENERAL DESCRIPTION —

ELECTRONIC IGNITION SYSTEM

Camshaft Position (CMP) Sensor

The camshaft position (CMP) sensor sends a signal to

the PCM. The PCM uses this signal as a ”sync pulse” to

trigger the injectors in the proper sequence. The PCM

uses the CMP signal to indicate the position of the #1

piston during its power stroke. The CMP allows the PCM

to calculate true sequential fuel injection (SFI) mode of

operation. If the PCM detects an incorrect CMP signal

while the engine is running, DTC P0341 will set.

If the CMP signal is lost while the engine is running, the

fuel injection system will shift to a calculated sequential

fuel injection mode based on the last fuel injection pulse,

and the engine will continue to run. It will run in the

calculated sequential mode with a 1–in–4 chance of the

injector being correct.

For additional information, refer to DTC P0342.

014RX007

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor provides a signal

used by the powertrain control module (PCM) to calculate

the ignition sequence. The sensor initiates the 58X

reference pulses which the PCM uses to calculate RPM

and crankshaft position. For additional information, refer

to Electronic Ignition System.

Electronic Ignition

The electronic ignition system controls fuel combustion

by providing a spark to ignite the compressed air/fuel

mixture at the correct time. To provide optimum engine

performance, fuel economy, and control of exhaust

emissions, the PCM controls the spark advance of the

ignition system. Electronic ignition has the following

advantages over a mechanical distributor system:

D

No moving parts.

D

Less maintenance.

D

Remote mounting capability.

D

No mechanical load on the engine.

D

More coil cooldown time between firing events.

D

Elimination of mechanical timing adjustments.

D

Increased available ignition coil saturation time.